4

05.01

4.1 Technical data

4-83

Siemens AG 2001 All rights reserved

SIMODRIVE 611 Planning Guide (PJU) – 05.01 Edition

4.1 Technical data

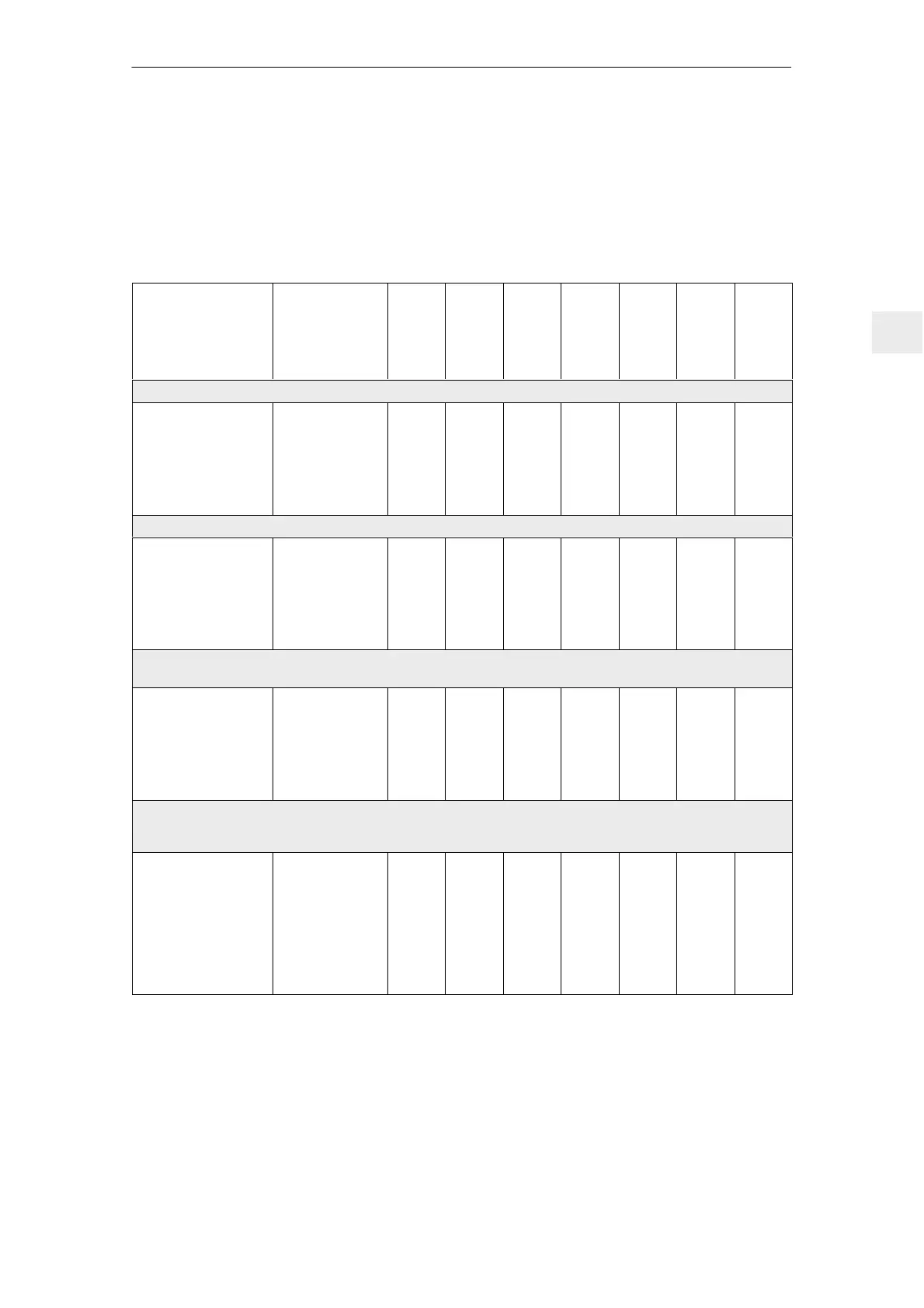

4.1.1 Technical data, power modules

Table 4-1 Technical data/power module, 1–axis version

Internal cooling

External cooling

Hose cooling

Cooling type

6SN 1123–1AA0.–

6SN 1124–1AA0.–

6SN 1123–1AA0.–

0HA1

0HA1

–

Non–

ventila-

ted

0AA1

0AA1

–

Non–

ventila-

ted

0BA1

0BA1

–

Force

ventila-

ted

0CA1

0CA1

–

Force

ventila-

ted

0DA1

0DA1

–

Force

ventila-

ted

0EA1

0EA1

–

Force

ventila-

ted

0FA1

0FA1

0FA1

Force

ventila-

ted

To use 1FT5 motors with control module 6SN11 18–0Ax11–xxxx

Rated current

Peak current

A

A

4

8

7.5

15

12.5

25

25

50

40

80

80

160

100

200

Power loss, total/

internal/external

3)

W 35 / 14 /

21

45 / 18 /

27

90 / 35 /

55

180 / 62

/ 118

300 / 30

/ 270

655 / 30

/ 625

740 / 90

/ 650

f

o

1)

X1

1)

kHz

%

3.3

55

3.3

55

3.3

55

3.3

40

3.3

50

3.3

55

3.3

55

To use 1FT6 motors/1FK6 motors with control module 6SN11 18–0Bx11–xxxx

Rated current

Peak current

A

A

3

6

5

10

9

18

18

36

28

56

56

112

70

140

Power loss, total/

internal/external

3)

W 35 / 14 /

21

50 / 19 /

31

90 / 35 /

55

190 / 65

/ 125

300 / 30

/ 270

645 / 25

/ 620

730 / 90

/ 640

f

o

1)

X1

1)

kHz

%

3.3

55

3.3

55

3.3

55

3.3

40

3.3

50

3.3

55

3.3

55

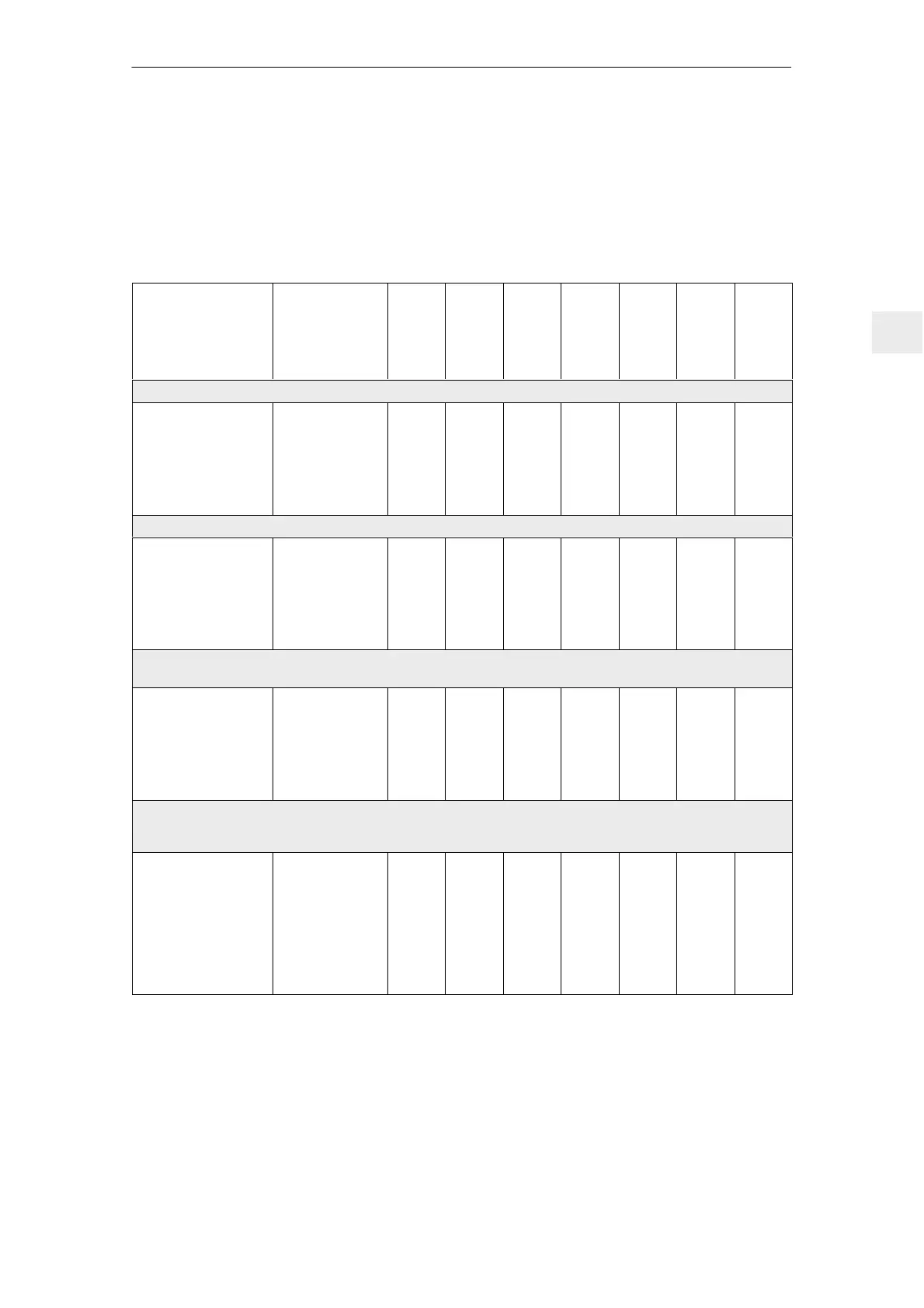

To use 1FT6 motors/1FK6 motors/1FN motors

with control module 6SN11 18–0Dx11–xxxx, 6SN11 18–xNxxx–xxxx

Rated current

Peak current

A

A

3

6

5

10

9

18

18

36

28

56

56

112

70

140

Power loss, total/

internal/external

3)

W 35 / 14 /

21

50 / 19 /

31

90 / 35 /

55

190 / 65

/ 125

300 / 30

/ 270

645 / 25

/ 620

730 / 90

/ 640

f

o

1)

X1

1)

kHz

%

4

55

4

55

4

55

4

50

4

50

4

55

4

55

To use 1PH and 1FE1 motors and induction motors

with control module 6SN11 21–0BA11–xxxx, 6SN11 22–0BA11–xxxx

To use 1PH and 1FE1 motors with control module 6SN11 18–0Dxxx–xxxx

Rated current

Current for S6–40%

Peak current

A

A

A

3

3

3

5

5

8

8

10

16

24

32

32

30

40

51

60

80

102

85

110

127

Power loss, total/

internal/external

3)

W 30 / 12 /

18

40 / 16 /

24

74 / 29 /

45

260 / 89

/ 171

320 / 32

/ 288

685 / 30

/ 655

850 /

100 /

750

f

o

1)

X1

1)

kHz

%

3.2

50

3.2

50

3.2

50

3.2

50

3.2

55

3.2

50

3.2

50

fo = inverter clock frequency

1) X1 = reduction factor of the current, current de–rating from the inverter clock frequency f

0

of the power transistors (Fig. 4-2)

2) The 1st number is valid for cable lugs, the 2nd number is valid for finely–stranded conductors without conn. sleeves.

3) If internal cooling or hose cooling is used, then only Pv

tot

should be considered.

4) For UL certification

:

only use copper cables designed for an operating temperature of w 60

4 Power Modules

Loading...

Loading...