5

05.01

5.6 Drive control with digital setpoint interface

5-126

Siemens AG 2001 All rights reserved

SIMODRIVE 611 Planning Guide (PJU) – 05.01 Edition

Notice

When using non–PELV circuits connected to terminals AS1, AS2, the connec-

tor must be prevented from being incorrectly inserted using plug coding (refer

to EN60204–1, Section 6.4).

Order No. of the coding, refer to Catalog NC 60.

!

Warning

Only PELV circuits may be connected to terminal 19.

5.6.1 Interface overview, drive control

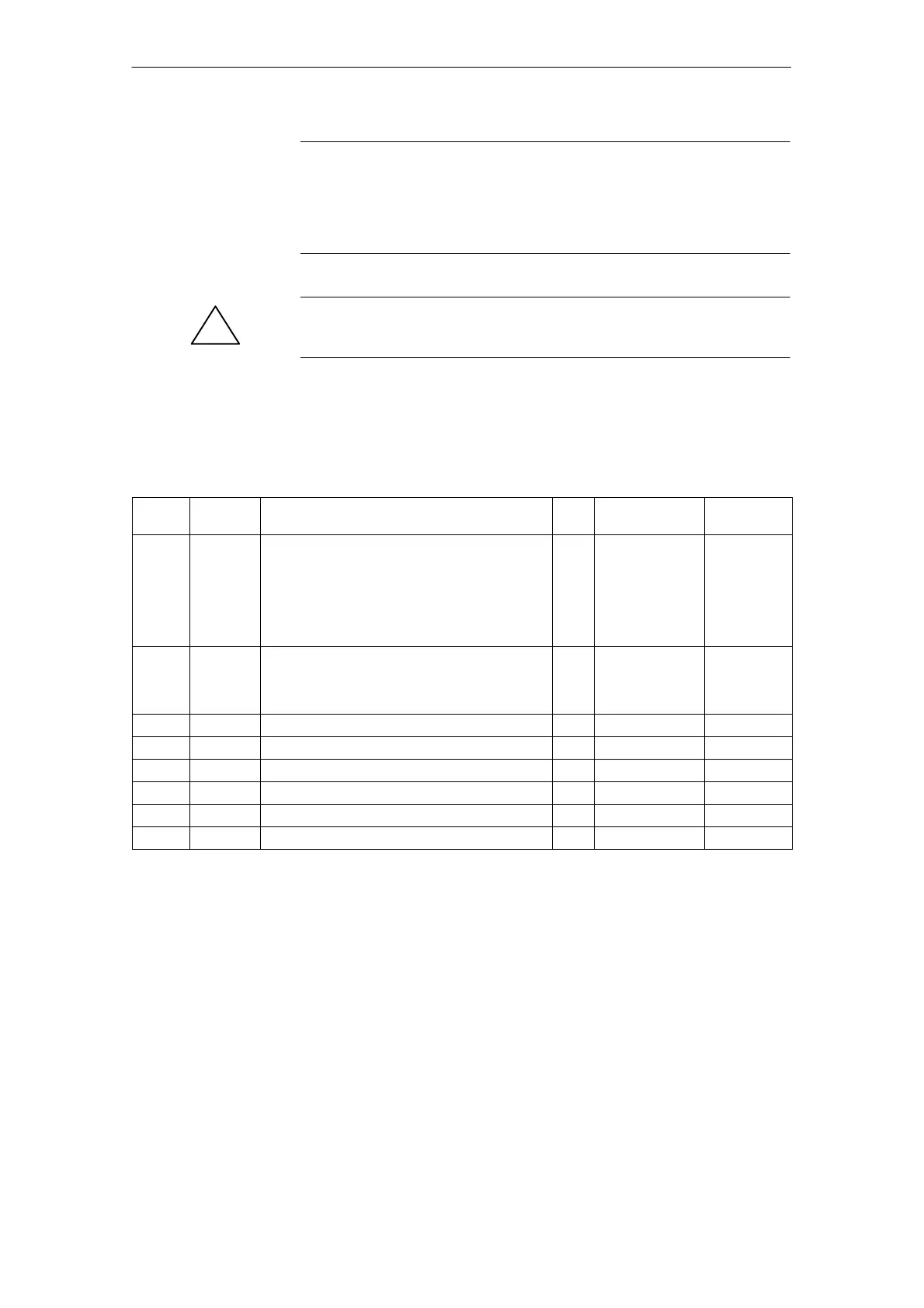

Table 5-16 Interface overview, drive control

Term.

No.

Desig. Function

Type

1)

Typ. voltage/

limit values

Max. cross–

sect.

9

663

AS1

AS2

X431

X431

X431

X431

Enable potential 2)

Pulse enable: The ”start inhibit” relay is switched

using terminal 663; when it opens, the gating pulses

are inhibited and the motor is switched into a no–

torque condition.

Relay, start inhibit (feedback signal. term. 663)

Relay, start inhibit (feedback signal, term. 663)

O

I

NC

+24 V

+21 V ... 30 V

max. 250VAC/1A

30 VDC/2 A

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

B1

19

B2

9

X432

X432

X432

X432

Input, external zero mark (BERO) axis 1

negative enable potential

Input, external zero mark (BERO) axis 2

positive enable potential 2)

I

O

I

O

+13 ... 30 V

0 V

+13 ... 30 V

+24 V

1.5 mm

2

1.5 mm

2

1.5 mm

2

1.5 mm

2

X411 Motor encoder, axis 1

X412 Motor encoder, axis 2

X421 Direct position encoder axis 1

X422 Direct position encoder axis 2

X151 Equipment bus (not labeled on the front panel)

X141/341 Drive bus

1) I=Input; O=Output; NC=NC contact; NO=NO contact (for signal NO=High/NC=Low)

2) The terminal may only be used to enable the associated drive group.

5 Control Modules

Loading...

Loading...