1A-192 Engine General Information and Diagnosis:

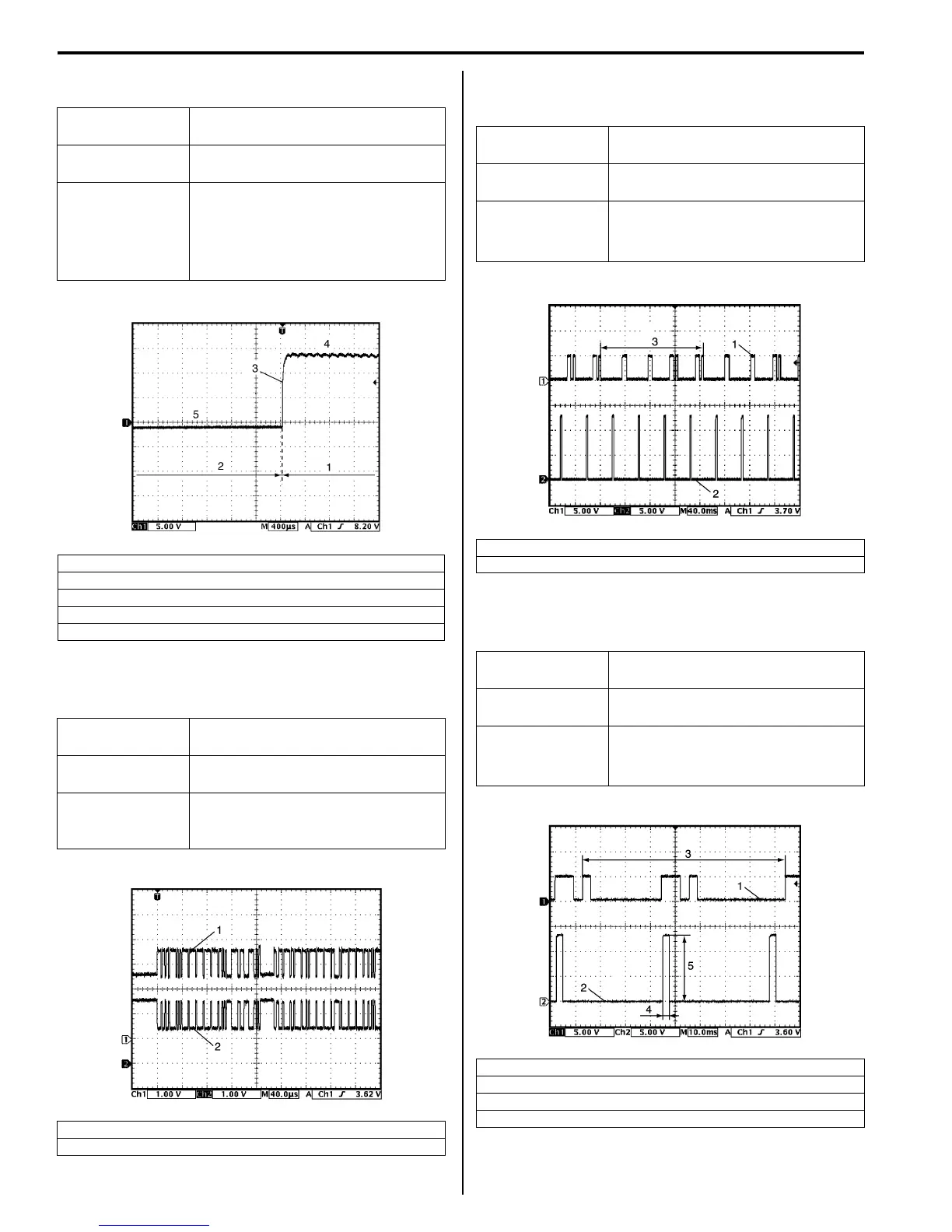

Reference waveform No.28

Oil control valve signal with engine racing

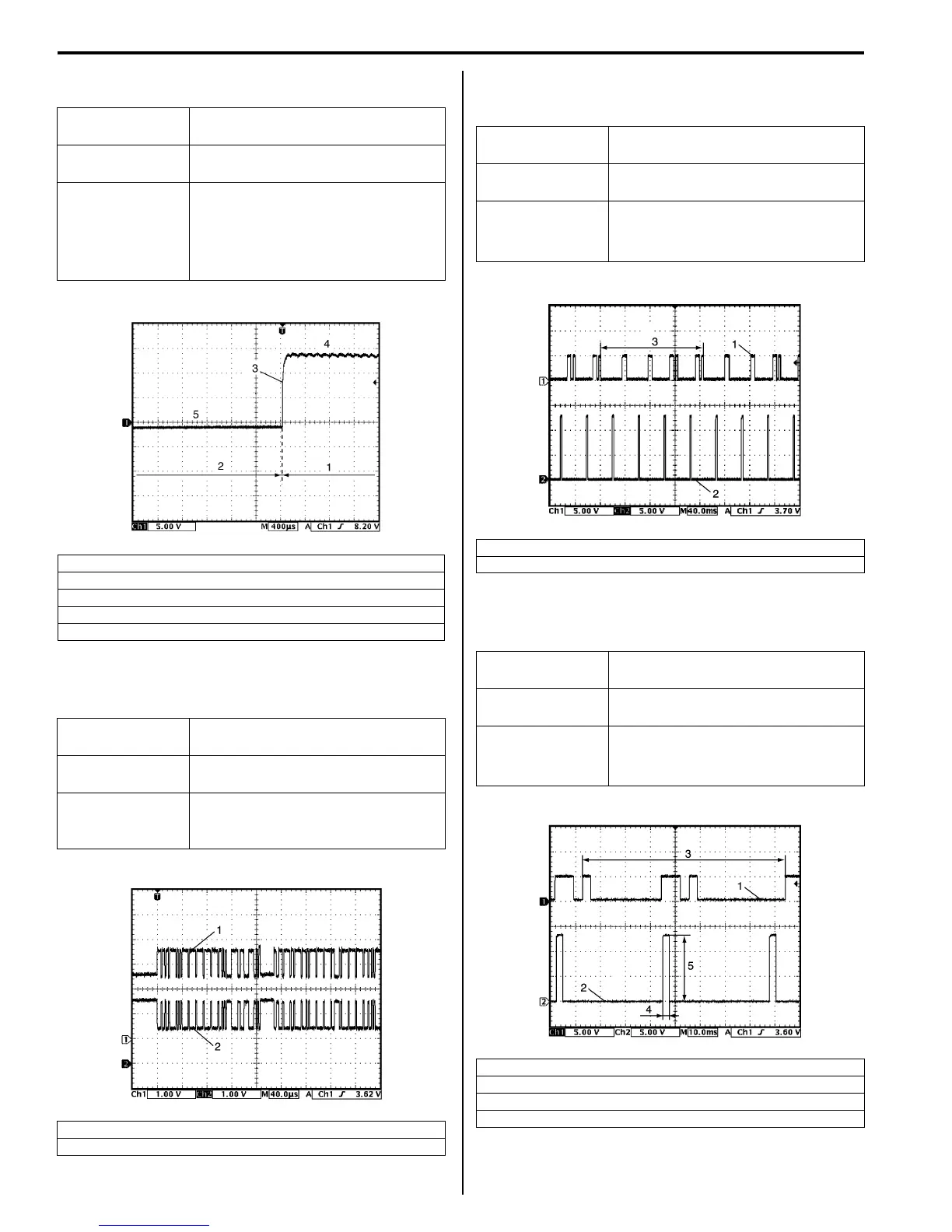

Reference waveform No.29

CAN communication line signal from each control

module with ignition switch turned ON

Reference waveform No.30

Ignition pulse (engine revolution) signal (2) with engine

idling

Reference waveform No.31

Ignition pulse (engine revolution) signal (2) with engine

idling

Measurement

terminal

CH1: “C37-60” to “C37-59”

Oscilloscope

setting

CH1: 5 V/DIV

TIME: 400 µs/DIV

Measurement

condition

• After warmed up to normal

operating temperature

• Vehicle driving at 20 km/h (12

mph) and depress accelerator

pedal fully

1. Accelerator pedal depressed fully

2. Accelerator pedal depressed partially

3. Oil control valve signal

4. ON signal

5. OFF signal

Measurement

terminal

CH1: “E23-3” to “C37-58”

CH2: “E23-18” to “C37-58”

Oscilloscope

setting

CH1: 1 V/DIV, CH2: 1 V/DIV

TIME: 40 µs/DIV

Measurement

condition

Ignition switch turned ON

(Signal pattern is depending on

engine condition)

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

I4RS0B110075-01

I4RS0B110076-01

Measurement

terminal

CH1: “C37-20” to “C37-58”

CH2: “E23-4” to “C37-58”

Oscilloscope

setting

CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 40 ms/DIV

Measurement

condition

• After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 720° crank angle

Measurement

terminal

CH1: “C37-20” to “C37-58”

CH2: “E23-4” to “C37-58”

Oscilloscope

setting

CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 10 ms/DIV

Measurement

condition

• After warmed up to normal

operating temperature

• Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 360° crank angle

4. 2 to 4 msec.

5. 10 – 14 V

I6RS0C110036-01

I6RS0C110037-01

Loading...

Loading...