Maintenance

1903−1/A1

Winterthur Gas & Diesel Ltd.

1/ 3

Pre-tension Checks and Tie Rod Replacement

Tools:

1 Feeler gauge 94122 1 Pressure gauge 94934A

2 Pre-tensioning jacks 94180 3 HP hoses 94935

1 Connection block 94934 1 Hydraulic unit 94942

1. General

We recommend that you check the tension of all the tie rods one year after

commissioning. If necessary, tension them to the specified value. After that follow the

maintenance schedule 0380−1.

2. Pre-tension Check

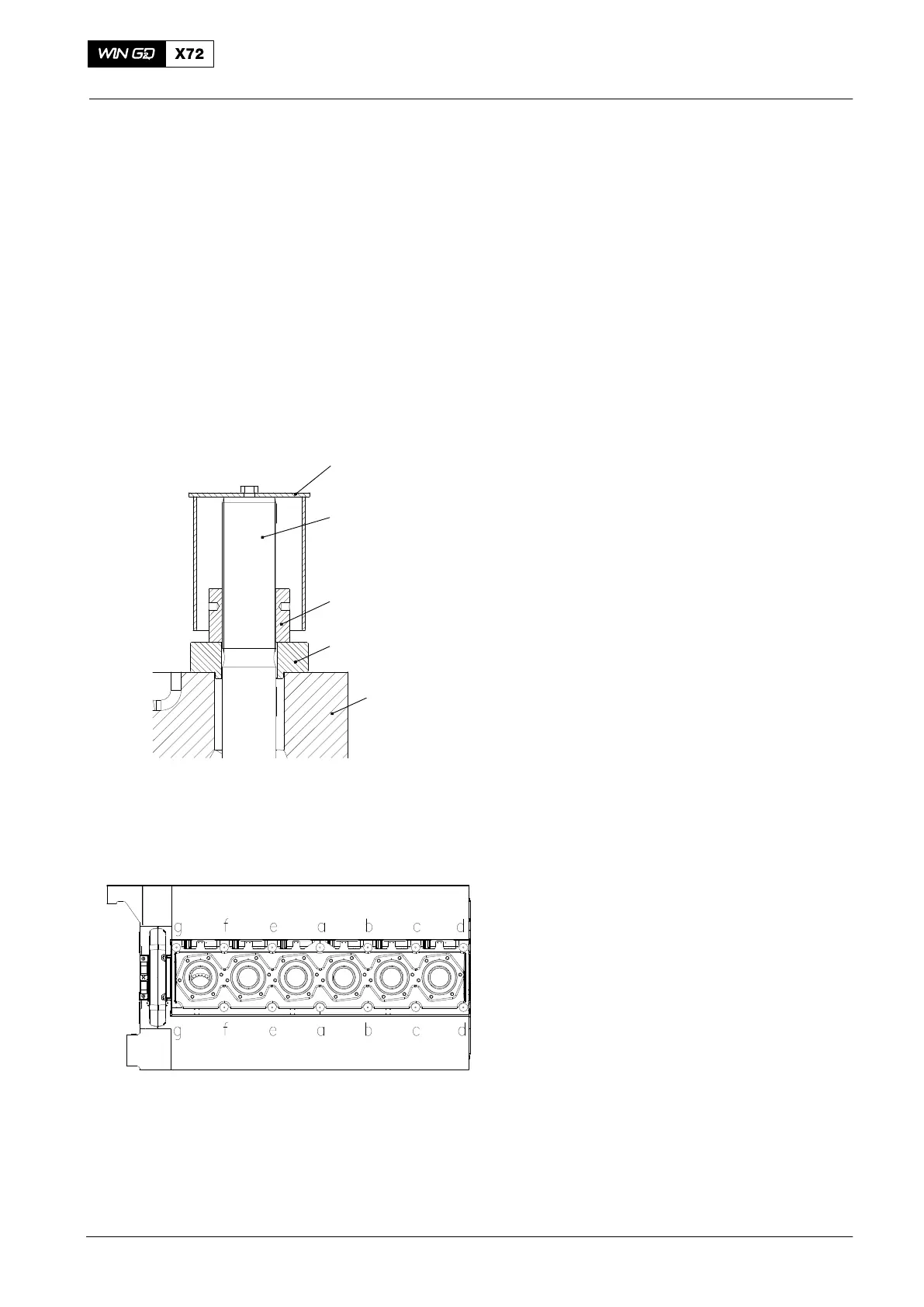

1) Remove the protection cover (5) from

all tie rods (4, Fig. 1).

2) Clean the surfaces of the intermediate

rings (2).

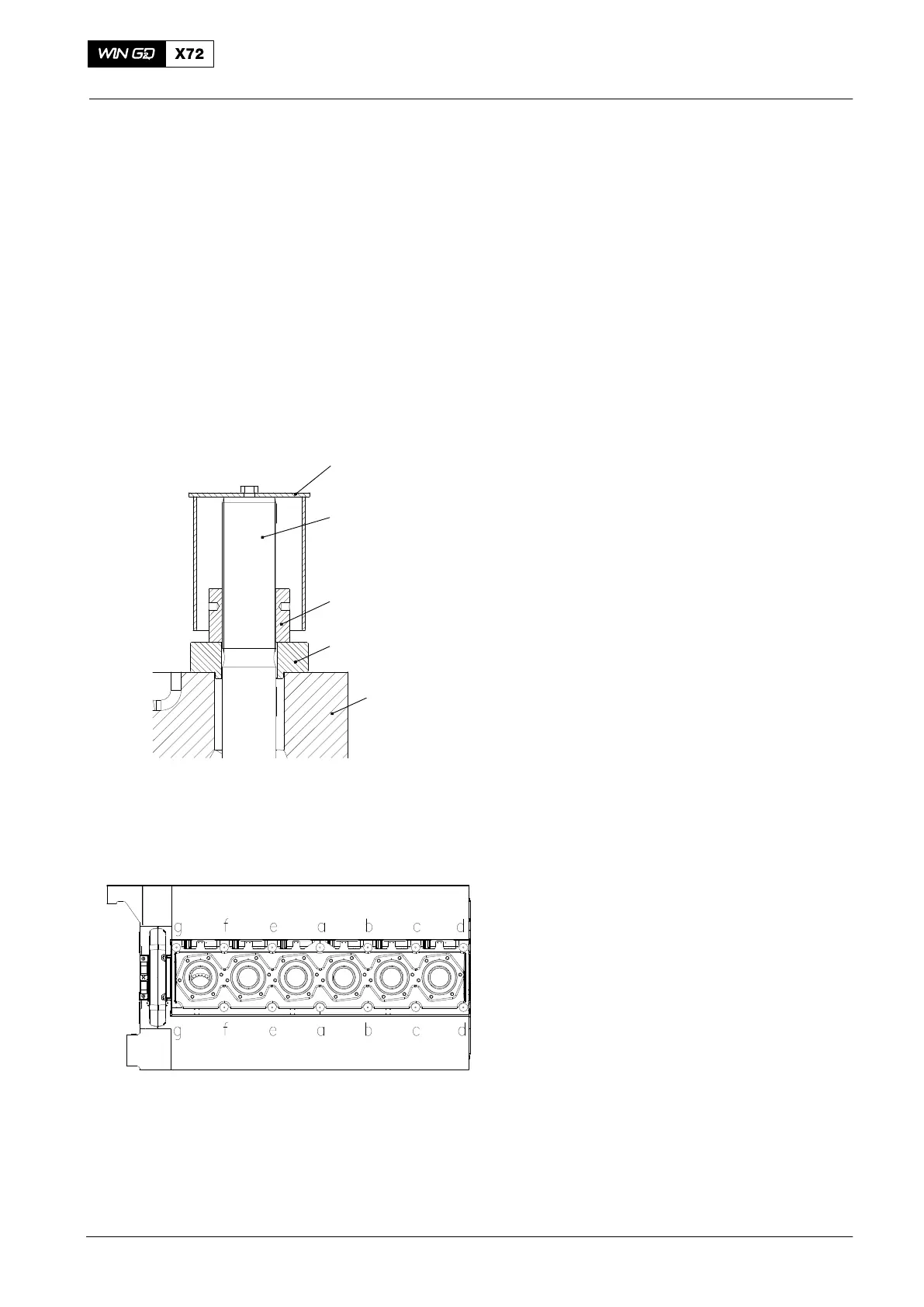

Note: Start with the tie rods in the middle

of the engine a−a, then b−b etc).

3) Attach the two pre-tensioning jacks

(94180) to the two tie rods (4, a−a)

refer to 9403−4.

4) Apply 1500 bar to the tie rods (4).

5) Tighten the round nuts (3) if possible.

6) If the round nut (3) will not move, do as

follows:

a) Put a brass or copper bar through

the slot in the jack and into a hole

in the round nut.

b) Use a hammer to loosen, then

tighten the nut. Make sure that the

edge of the hole has no

deformation.

7) Remove the pre-tensioning jacks, refer

to 9304−4.

8) Apply a layer of Molykote paste G to

the threads of the tie rod (4) to prevent

corrosion.

9) Install the protection cover (5).

10) Do step 1) to step 9) for the remaining

tie rods.

Tie Rod

2015

5

2

4

3

1

WCH02345

Fig. 1

DRIVING END

FREE END

WCH02345

Loading...

Loading...