Maintenance

3425−1/A1

Winterthur Gas & Diesel Ltd.

5/ 9

3. Piston Ring Grooves

Do a check of all dimensions and record them (see 0330−1 Pistons and Piston

Rings). These records are important for an analysis of the running gear and must

include the data that follow:

D All dimensions

D The date of the overhaul

D The operation hours of the different components

D The operation hours of the engine.

3.1 Piston Ring Clearance

(Piston Installed)

WARNING

Injury Hazard: Before you

operate the turning gear,

make sure that no

personnel are near the

flywheel, or in the engine.

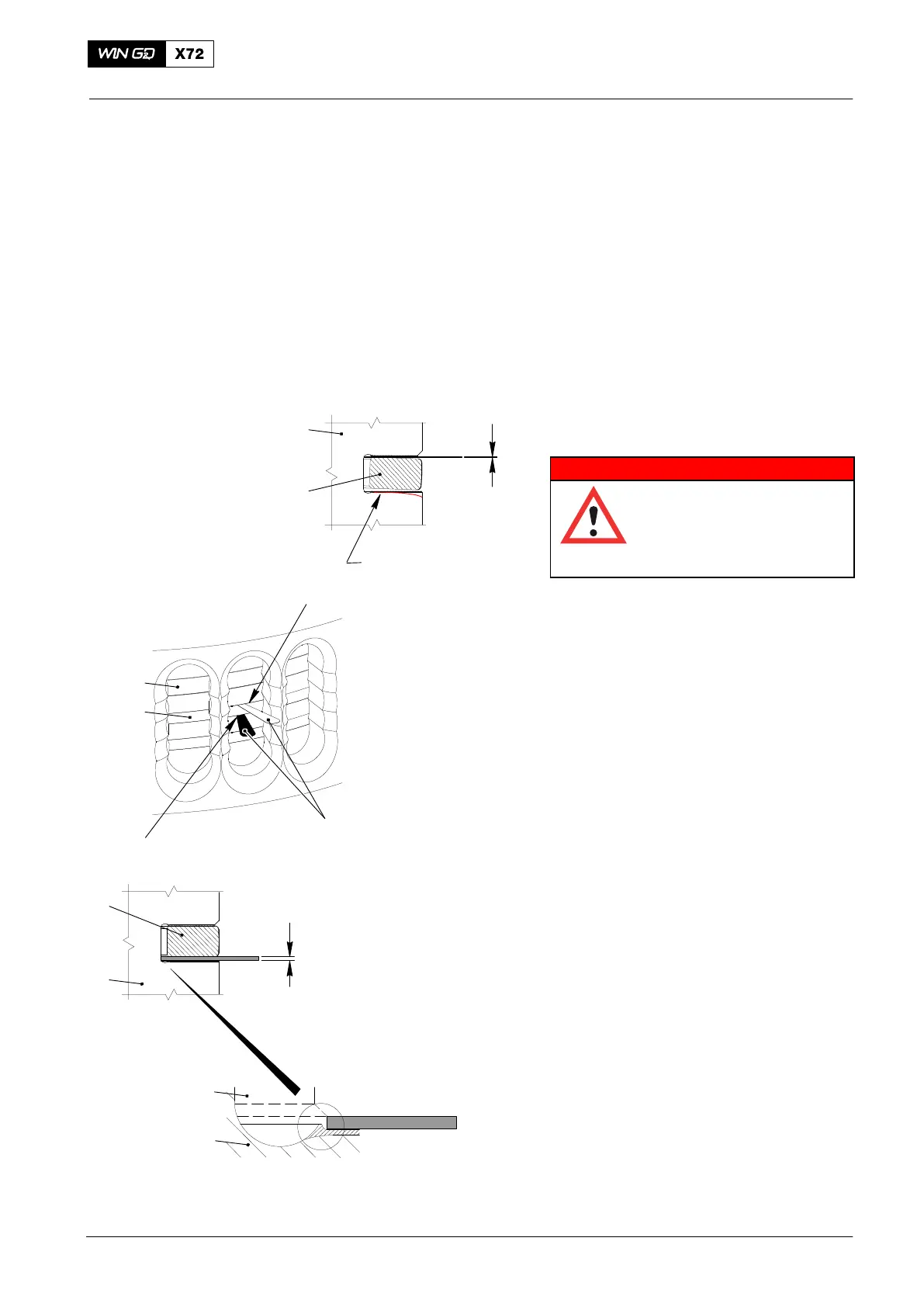

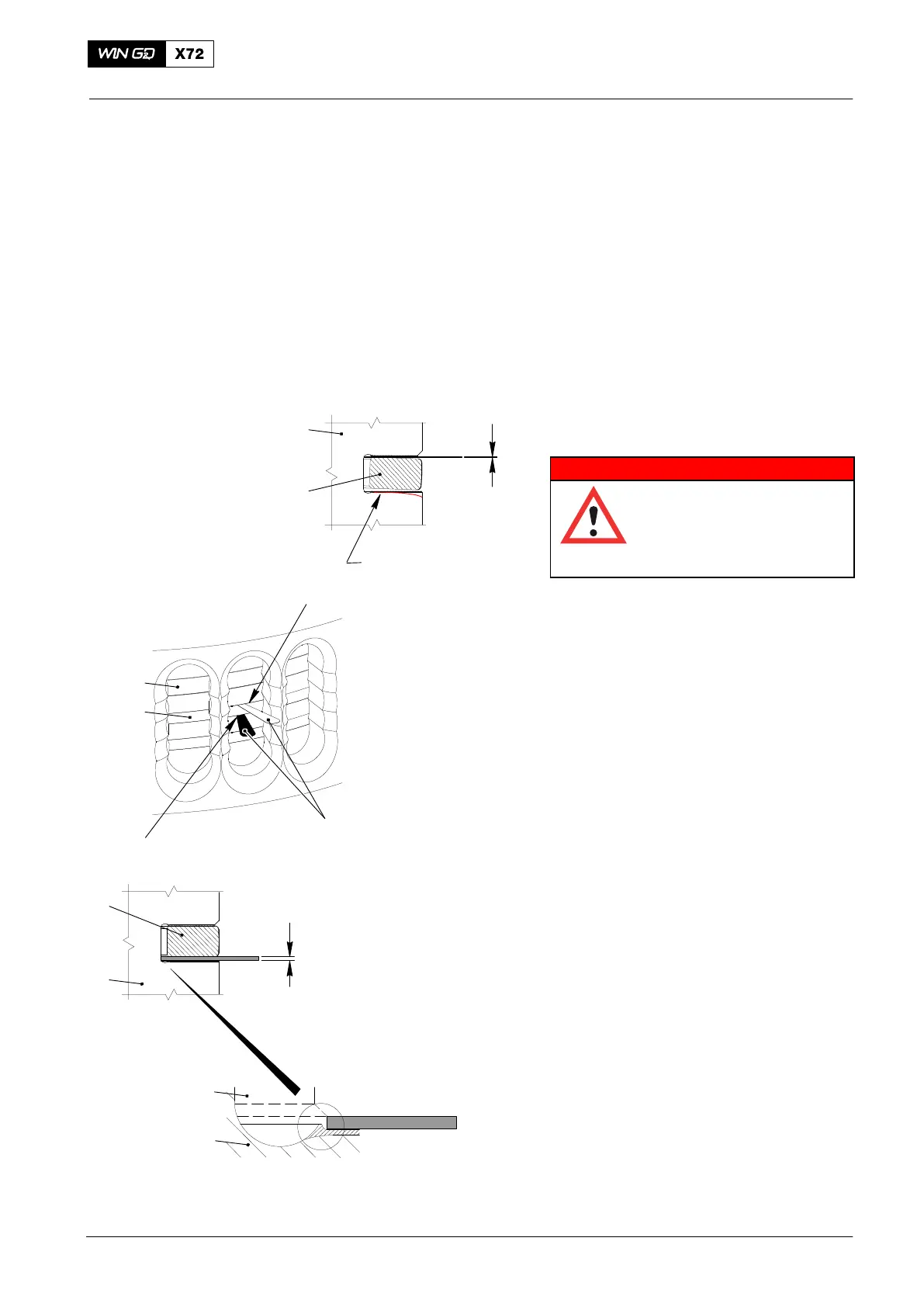

1) Use the turning gear to move the piston

(2, Fig. 3) down until you can see the

piston rings.

Note: Push the feeler gage fully into the

piston ring groove. This will make

sure that the feeler gage will touch

the inner diameter of the groove.

2) Measure the clearance X1 at Point A. If

there is a wear step on the

chrome-ceramic layer, you can push

the feeler gage only to that point.

3) Measure the clearance at X2.

4) Do step 2) and step 3) at between two

and four different locations around the

piston (2).

The sum of each value from X1and X2 will

give the total piston ring clearance.

The maximum clearance is at point A. For

the maximum wear data, refer to 0330−1

Pistons and Piston Rings.

5) If the clearance at point A is more than

the permitted value, do step a) and

step b).

a) Replace the piston rings.

b) Repair the piston head.

Note: For the repair of piston heads,

speak to the nearest WinGD

Service Center.

Piston Rings: Wear of Piston Rings and Ring Grooves

2015

2

94122

1

WCH02244

Fig. 3

1

2

Wear Step On

Chrome-ceramic Layer

2

1

X2

2

1

Possible Wear

Shape On Piston

Groove

X2

X1

A

X1

Loading...

Loading...