Maintenance

2751−4/A1

Winterthur Gas & Diesel Ltd.

1/ 2

Valve Head − Grind the Seating Surface

Tools:

1 Feeler gauge 94122

1 Tool, valve grinding device 94291

1 Template 94292

1. General

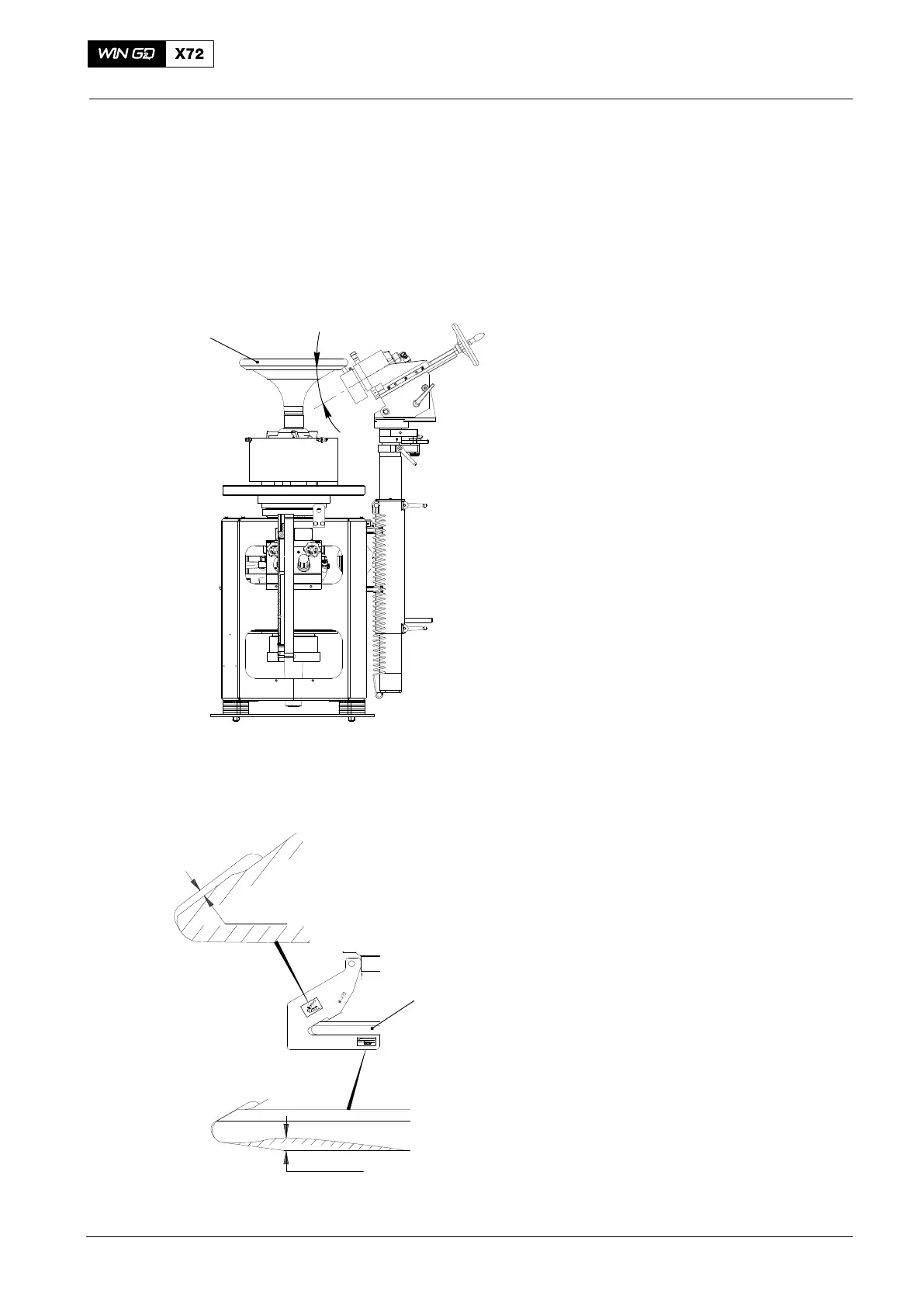

Use only the tool (94291, Fig. 1) to grind the

valve head.

You must grind valve heads that have

damage or corrosion on the seating surface.

If the rotation wing is missing from the valve

spindle, do not grind the valve head.

2. Valve Head − Grind

1) Read the data in the manufacturer’s

manual for the grinding tool (94291).

2) Put the grinding tool (94291) in an

area where there is no vibration.

Note: If necessary, put the tool on a

rubber mat. This will help to

prevent rough surfaces during the

grinding procedure.

3) Put the valve spindle in position in the

tool (94291).

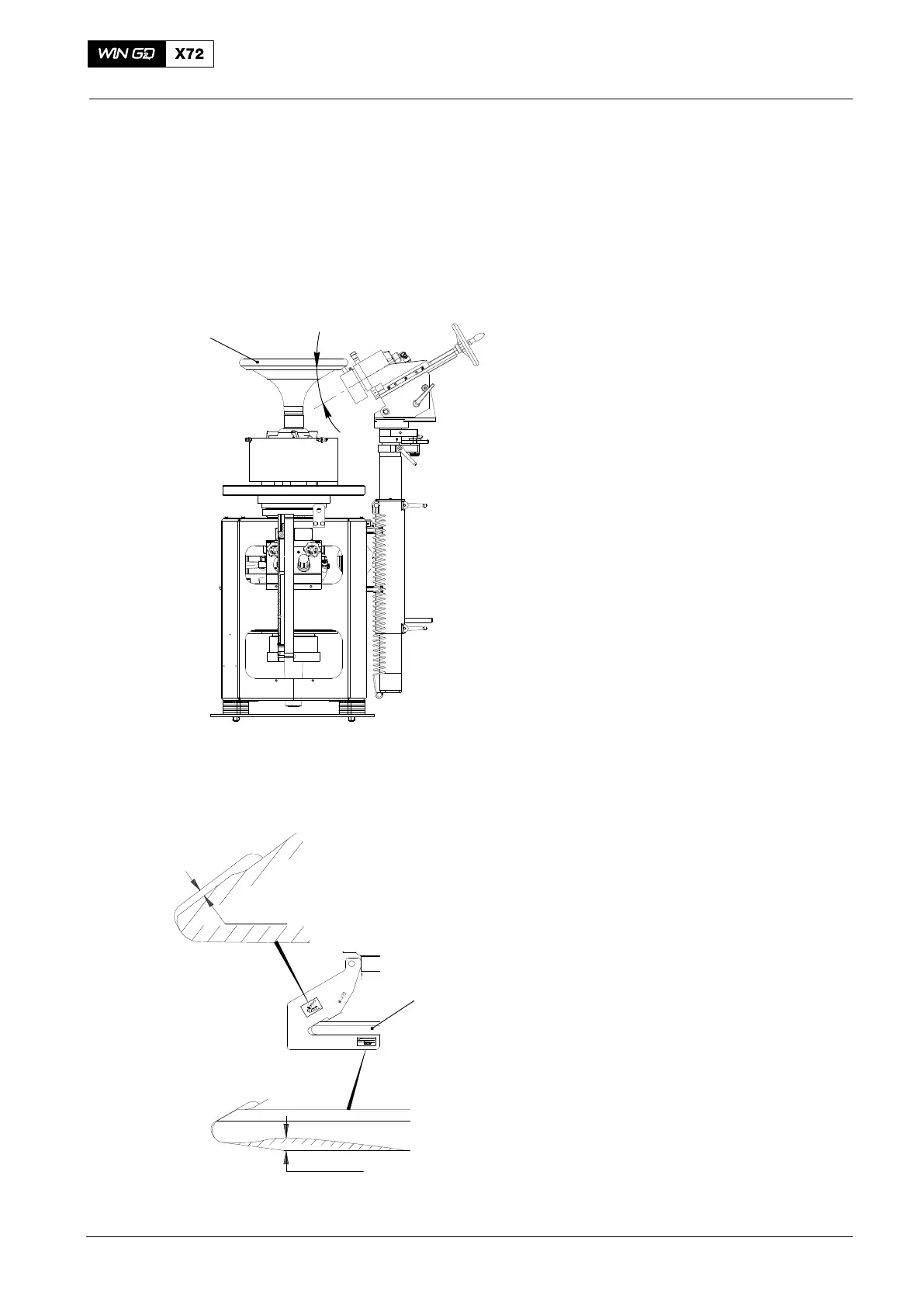

4) Put the gauge (94292) on the valve

head (1, Fig. 2).

Note: The data shown on the

gauge (94292) shows the

maximum limits for the valve head.

5) Use the feeler gauge tool (94122) to

measure the values.

6) If the values are less than the limits

given, do step a) to step c):

a) Use the tool (94291) to grind the

surface of the valve head (1).

Remove only the minimum

material necessary to get a

smooth, flat surface.

b) Use an applicable coolant to keep

the valve head (1) cool.

c) Keep the angle of the valve head

(1) to between 30°16' and 30°18'.

Note: You can grind off a maximum of

3.0 mm from the seating surface.

7) Do a check of the valve seat and valve

spindle, see2751−3, paragraph 5.

Exhaust Valve

2015

WCH03263

a

a = between:

30°16' and 30°18'

WCH03263

1

1

Fig. 1

Fig. 2

Max. 9.0 mm

Max. 3.0 mm

Loading...

Loading...