Maintenance

3326−1/A1

Winterthur Gas & Diesel Ltd.

1/ 1

Clearance Checks

Tools:

1 Feeler gauge 94238

1. General

During an overhaul or after the installation of

the crosshead, you must do as follows:

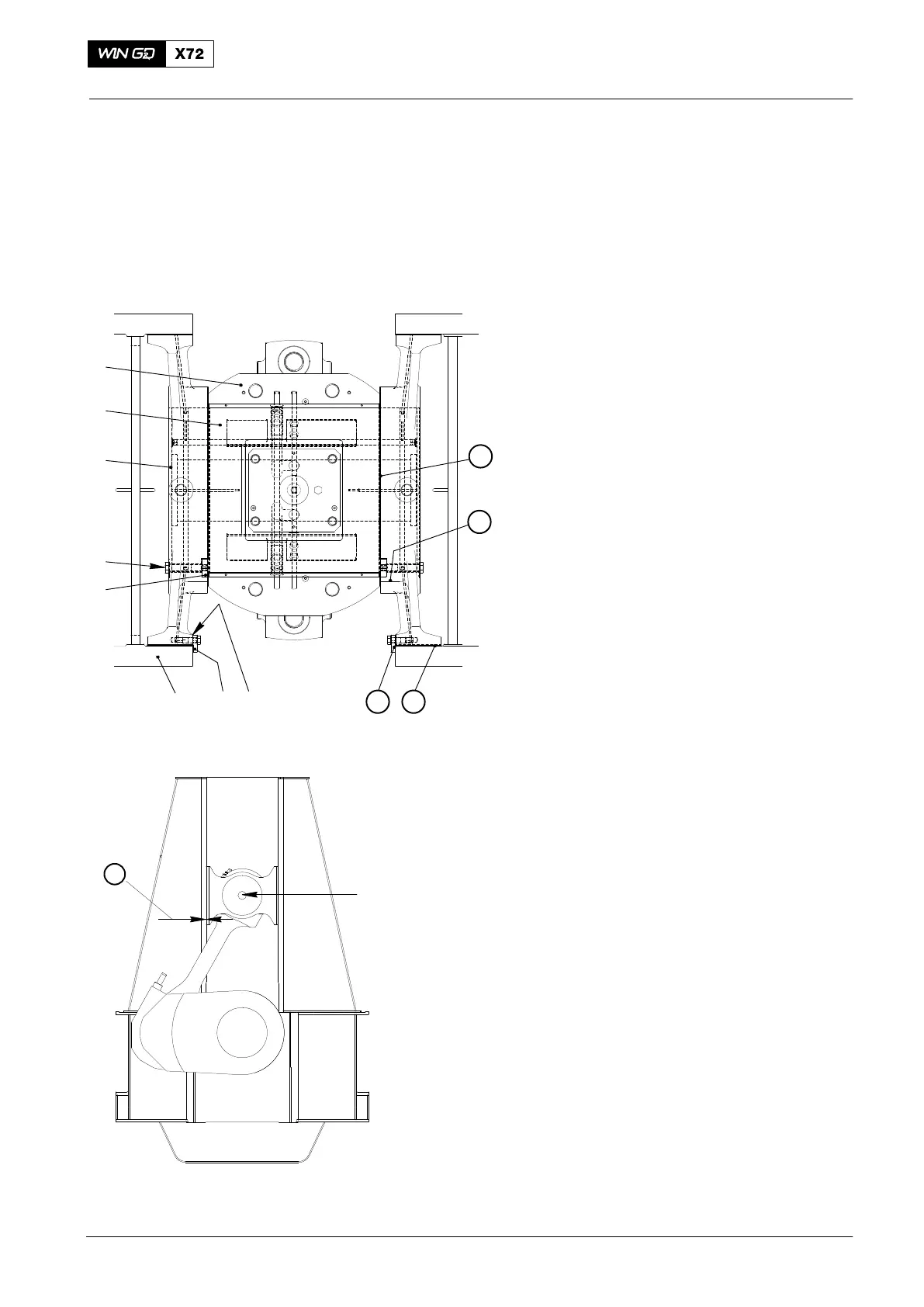

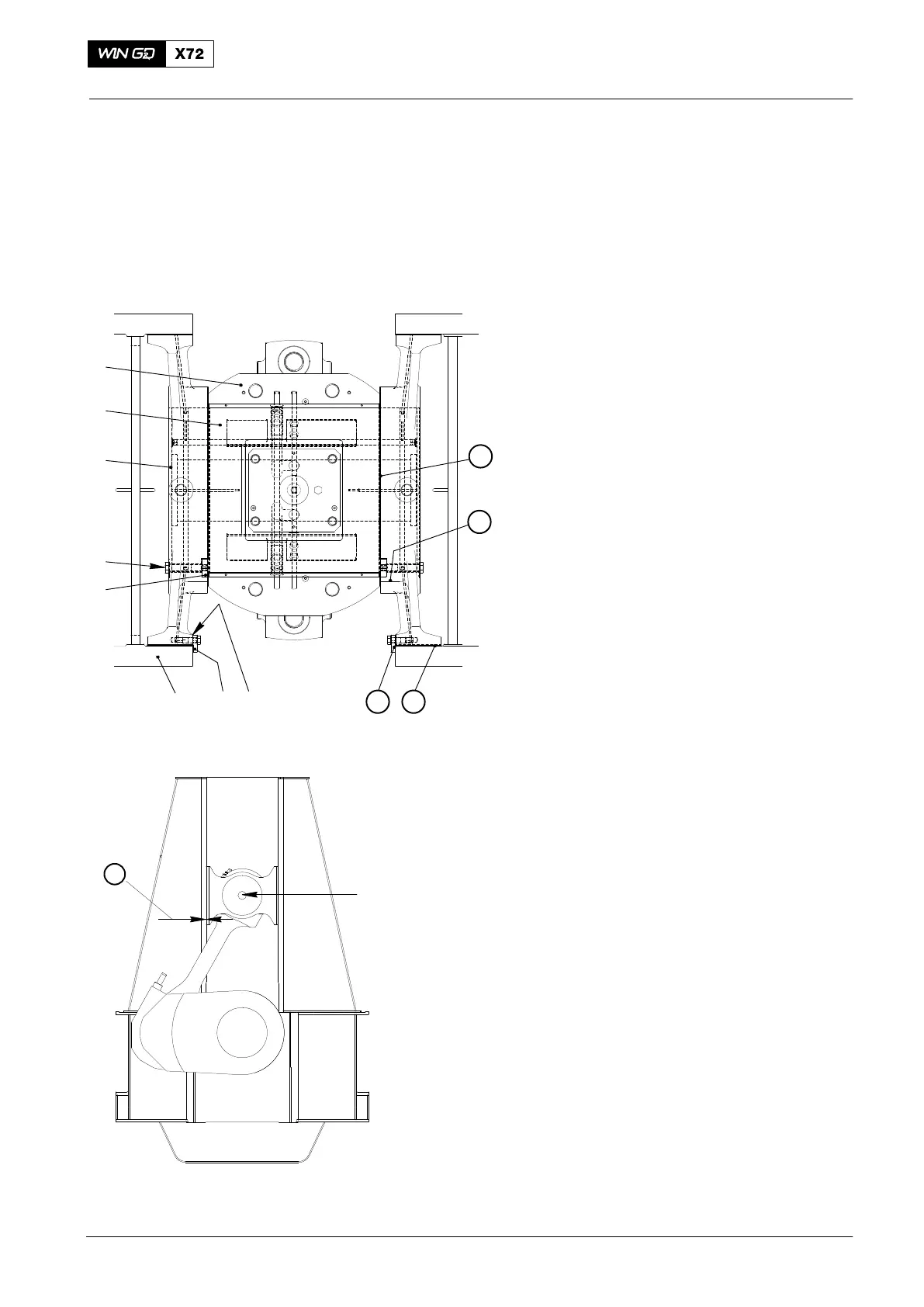

D Measure and record the clearances

shown in Fig. 1 and Fig. 2.

D Compare the clearances with those

given in 0330−1 Clearance Table.

2. Clearance Checks

2.1 Guide Shoe and Guide Way

1) Make sure that the related crank pin is

in a position so that the guide shoes(6)

touch the guide ways (3) on the fuel

side (or exhaust side).

2) Measure the clearance

j between the

guide shoe (6) and the guide way (3).

Note: The clearance

j is applicable for

the full length of the guide way (3)

and measured at the position

shown in Fig. 2.

2.2 Crosshead

1) Measure the lateral clearance k at

each position of the crosshead as

follows:

a) Use an applicable hardwood

wedge (or an item that is almost

the same) to push the crosshead

axially to one side. Make sure that

you apply the pressure only to the

guide shoe.

2.3 Guide Shoe and Top End

Bearing

1) Measure the full lateral clearance l

between the top end bearing (8) and

the the guide shoes (6).

2.4 Radial Clearance

1) Measure the radial clearance m

between the guide shoe (6) and

crosshead pin at all positions of the

crosshead.

2015

Crosshead

1

90° BEFORE OR

AFTER TDC

4

5

6

8

7

123

3

4

2 1

013.784/06

WCH02430

Fig. 1

Fig. 2

Loading...

Loading...