Maintenance3425−1/A1

Winterthur Gas & Diesel Ltd.

2/ 9

2. Piston Rings − Rate of Wear

2.1 Chrome-Ceramic Layer − Piston Installed

WARNING

Injury Hazard: Before you operate the turning gear, make sure

that no personnel are near the flywheel, or in the engine.

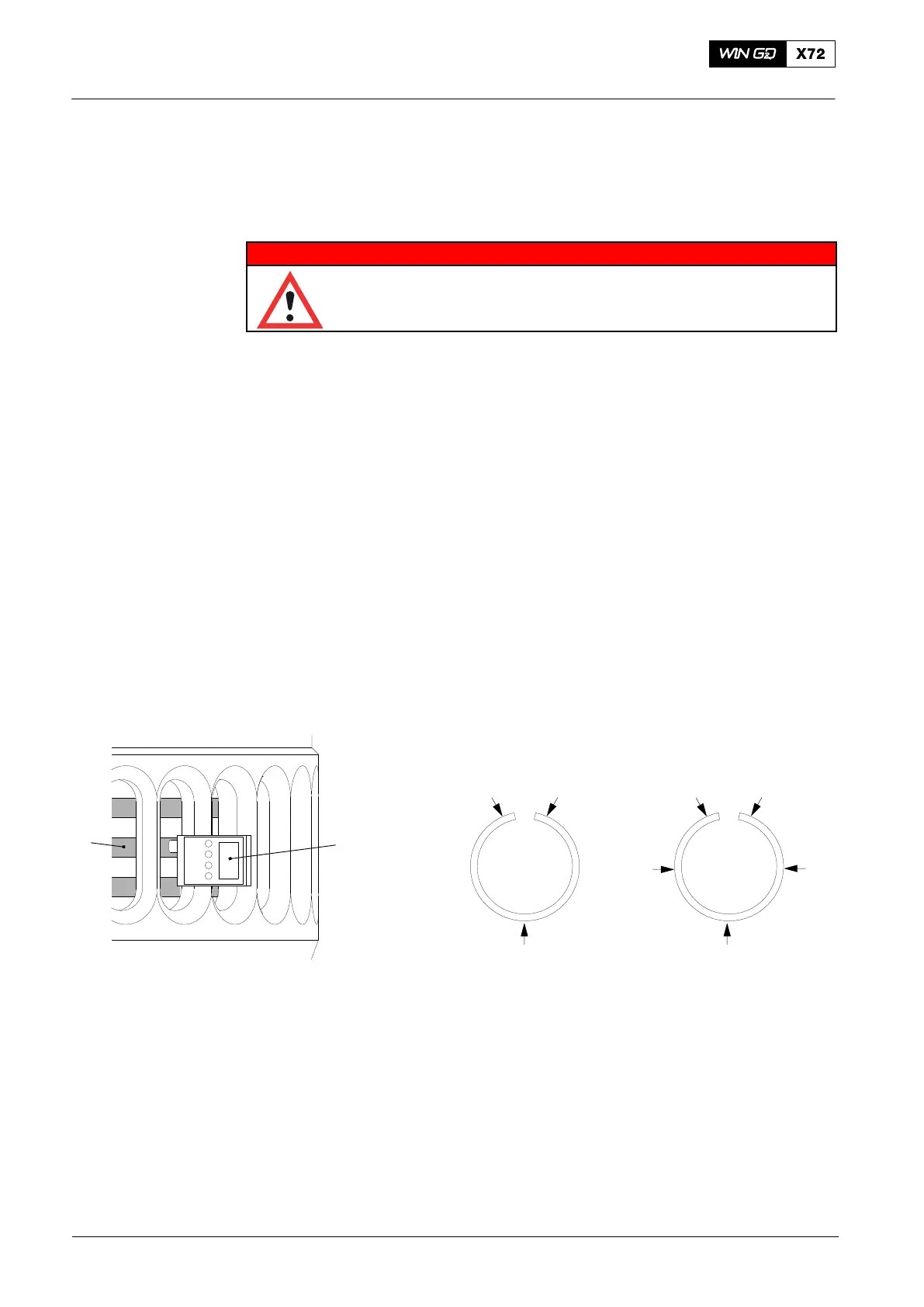

1) Read the data in the suppler documentation for the tool Permascope MP0

(94356).

2) Calibrate the Permascope MP0 (94356). Use the calibration foils and the top

flank of a spare top piston ring to get a correct setting.

3) Use the turning gear to move the piston almost to BDC (so that you can see the

piston rings).

4) Clean the surface of the piston ring (1, Fig. 1) at the locations P1 to P9.

5) Put the sensor of the Permascope MP0 (94356) against the middle of the piston

ring (1).

6) Record the value on the digital display of the Permascope MP0 (94356).

7) Compare the measured data with the limits given in 0330−1 Clearance Table,

Piston and Piston Rings. If the recorded data is not in the limits given, you must

do an overhaul of the piston head.

94356

1

P3

P5

P7

P1P9

P5

P1P9

Fig. 1

WCH01216

Locations to Measure the Thickness of the

Chrome-ceramic Layer on the Piston Ring

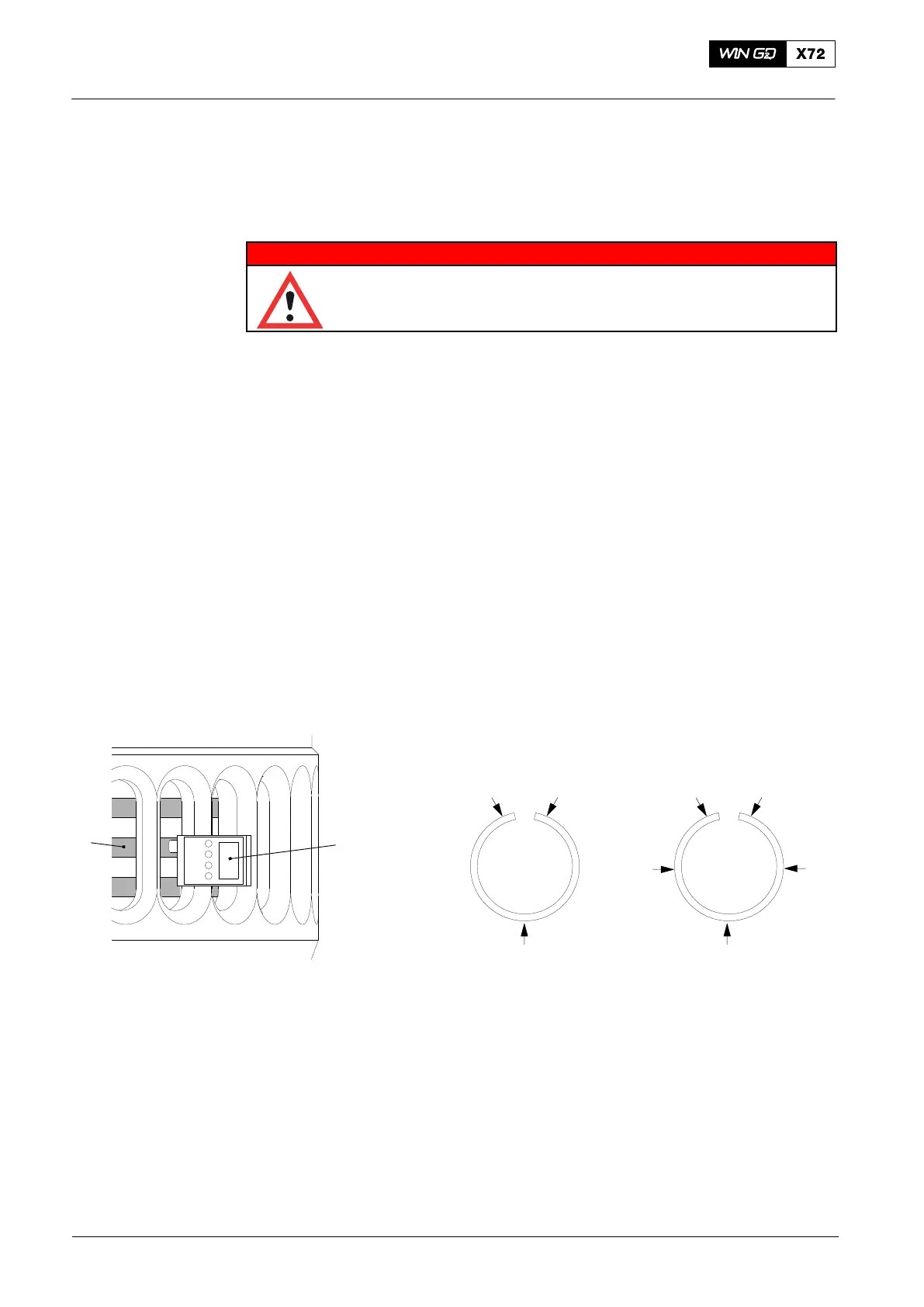

Minimum

Recommended

Piston Rings: Wear of Piston Rings and Ring Grooves

2015

Loading...

Loading...