Maintenance

3403−3/A1

Winterthur Gas & Diesel Ltd.

1/ 4

Disassemble and Assemble

Tools:

3 Pre-tensioning jacks 94340 3* Jacking screws 94364A

1 Suspension device 94341 2* Jacking screws 94364B

1 Piston support device 94350 3* Jacking screws 94364C

* Use available screws from

piston assembly

1. Preparation

CAUTION

Damage Hazard: When you disassemble or assemble a piston,

make sure that you do not damage the pipes or nozzles.

Note: You disassemble a piston to clean the cooling chamber in the piston

head, do an overhaul of the ring grooves etc.

1) Read the data in 0012−1 General Guidelines for Lifting Tools.

2) Remove the piston, refer to 3403−1, paragraph 1 and paragraph 2.

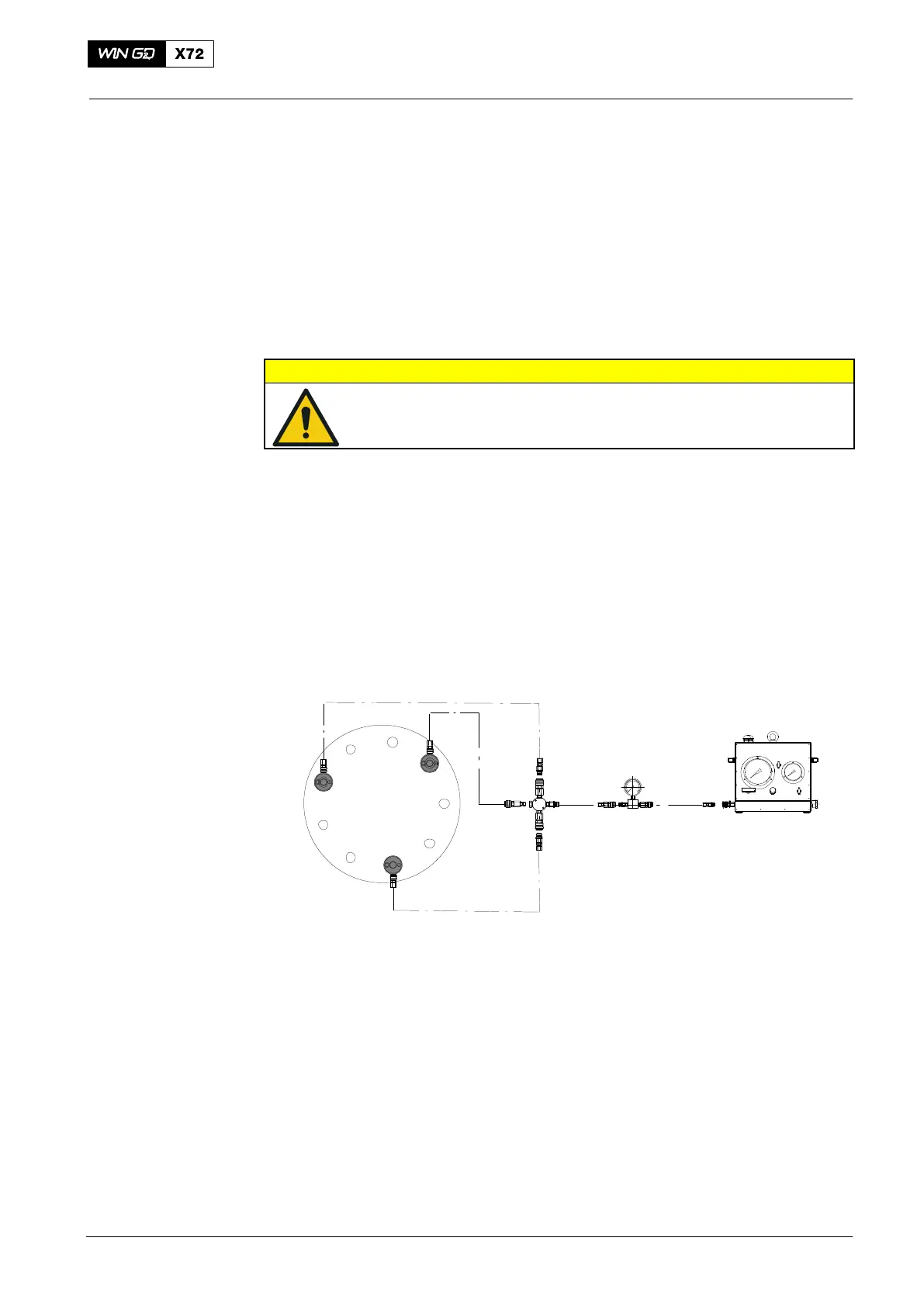

Note: When you do step 3), apply tension to the elastic bolts in the sequence

given in Fig. 1.

3) Apply tension to the elastic bolts (1), refer to 9403−4.

4) Remove the nine round nuts.

a

a

a

b

b

b

c

c

c

Fig. 1: Sequence to Apply Tension to the Elastic Bolts

2015

Piston

Loading...

Loading...