Maintenance

6545−1/A1

Winterthur Gas & Diesel Ltd.

1/ 7

Maintenance

Tools:

2 Lever chain hoist 94016-009 1 Chain (asymmetric) 94019A

2 Spur gear chain block 94017-006 1 Trolley 94021

4 Shackle 94018C 2 Sling 94650

1. General 1..........................................................

2. Procedure One 2...................................................

2.1 Preparation 2.................................................

2.2 Removal 2....................................................

2.3 Installation 4.................................................

3. Procedure Two 5...................................................

3.1 Preparation 5.................................................

3.2 Removal 5....................................................

3.3 Installation 6.................................................

1. General

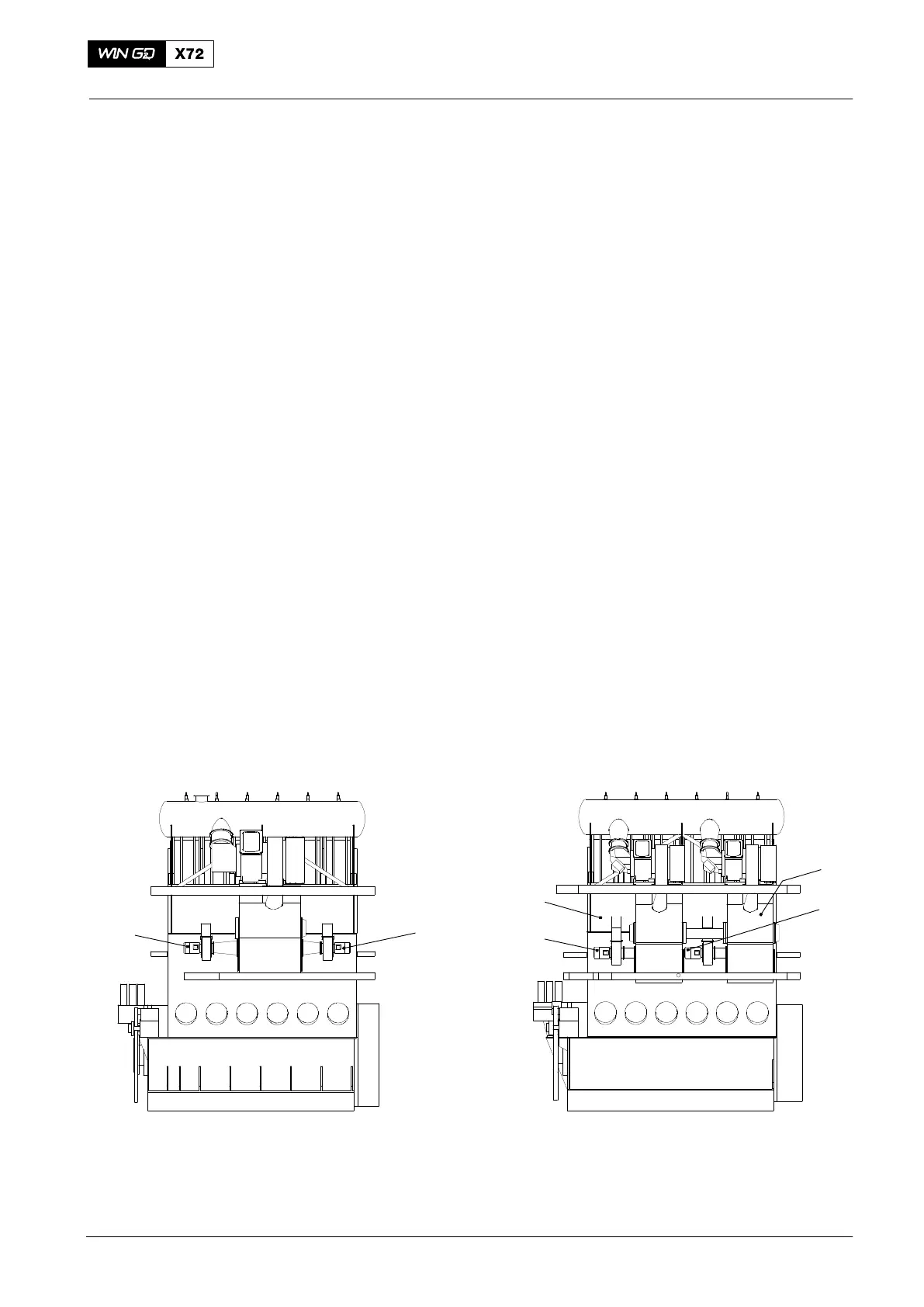

Two auxiliary blowers (2, Fig. 1) are attached to the scavenge air receiver (1). For

more data about the auxiliary blower, see the Operation Manual 6545-1 Auxiliary

Blower and Switch Box.

There are two procedures to remove and install an electric motor:

D Procedure One: For engines with one turbocharger, see the procedure given in

paragraph 2.

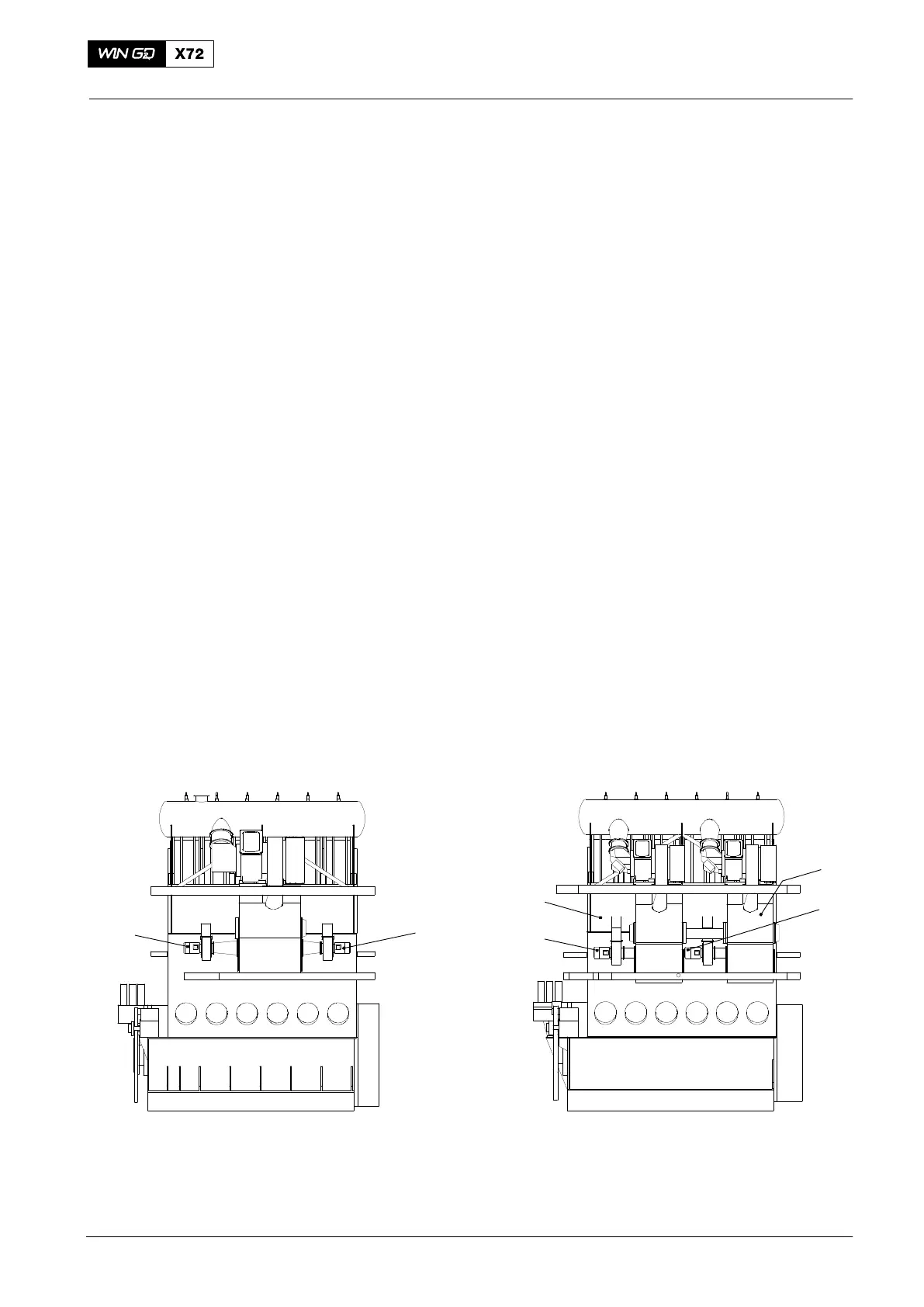

D Procedure Two: One of the electric motors (4) is installed between the two

scavenge air receivers (3, 6). The procedure to remove and install this electric

motor is given in paragraph 3).

Note: Also use Procedure One to remove and install the outer electric motor (5)

on an engine with two turbochargers.

For data about the procedure to clean the impeller and to replace the ball bearing,

see the documentation of the auxiliary blower manufacturer.

Fig. 1

5

4

3

2

1

WCH02413 WCH02413

6

Engine with One Turbocharger Engine with Two Turbochargers

2015

Auxiliary Blower

Loading...

Loading...