Maintenance2722−2/A1

Winterthur Gas & Diesel Ltd.

4/ 8

4. Disassemble

4.1 Injection Valve

1) Make sure that the test bench has no

pressure.

2) Remove the receiver (2, Fig. 1) from

the valve holder (94273).

3) Make sure that the HP hose (94275) is

disconnected from the connecting

piece (94272B).

4) Make sure that the leakage oil hose

(94275B) is disconnected from the

injection valve.

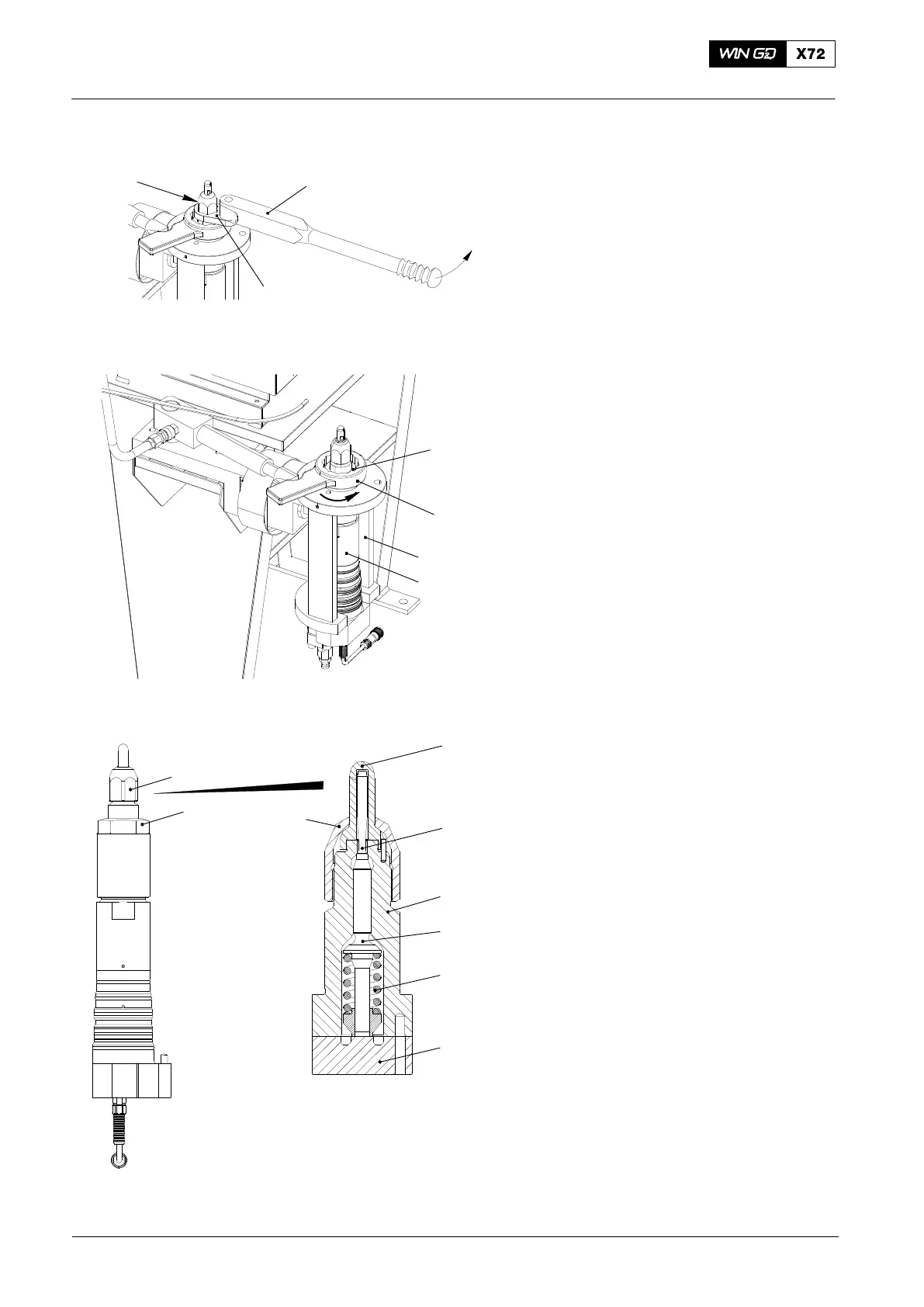

5) Turn the valve holder through 180_ into

the vertical position (see Fig. 2).

6) Use the torque spanner (94011A) and

adapter (94269C-41) to carefully

loosen the locknut (1).

7) Remove the locknut (1).

8) Use the wrench (94269A-70) and the

hydraulic cylinder (94269B) to loosen

the coupling nut (2).

9) Remove the coupling nut (2).

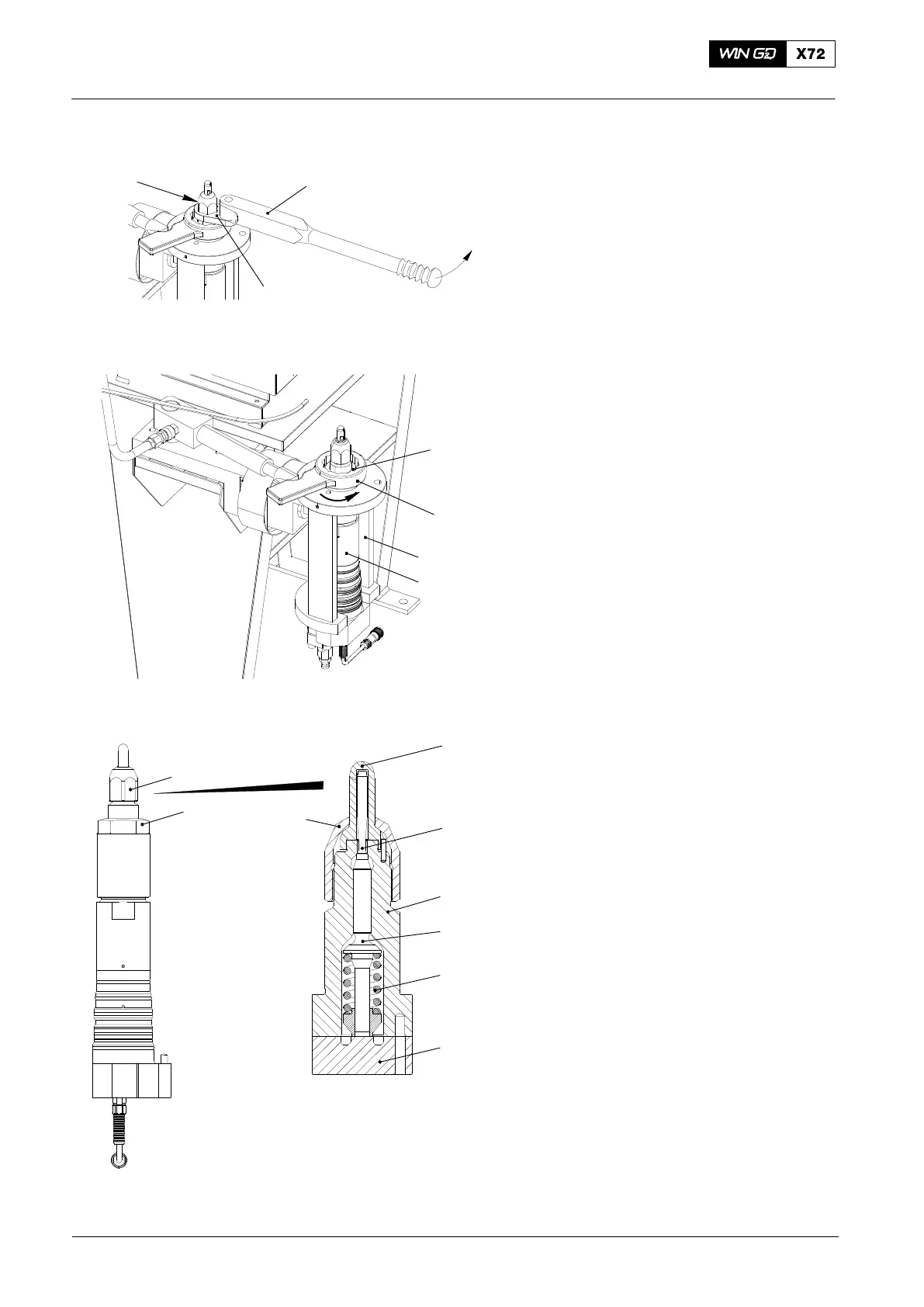

10) Remove the nozzle body (8) together

with the:

D Intermediate plate (11)

D Compression spring (10).

D Tappet (9)

D Needle (7)

D Nozzle tip (6).

Note: The needle (7) and nozzle body (8)

are machined together so that their

sealing surfaces have the same

contours. You must keep these

items together. If it is necessary to

replace the needle or the nozzle

body, you must replace the two

items. Do not replace only one

item.

11) If it is necessary to remove the nozzle

tip (6) from the nozzle body (8), do the

procedure in paragraph 5.

12) Remove the intermediate plate (11).

13) Remove the compression spring (10),

the tappet (9) and the needle (7).

2015

Injection Valve: Disassemble, Checks, Assemble Injection Valve with FAST

94269C−41

94011A

94269A-70

WCH02422

94273

WCH02401

Fig. 2

1

2

3

4

5

8

11

7

9

10

6

12

Loading...

Loading...