Maintenance

2708−3/A1

Winterthur Gas & Diesel Ltd.

1/ 1

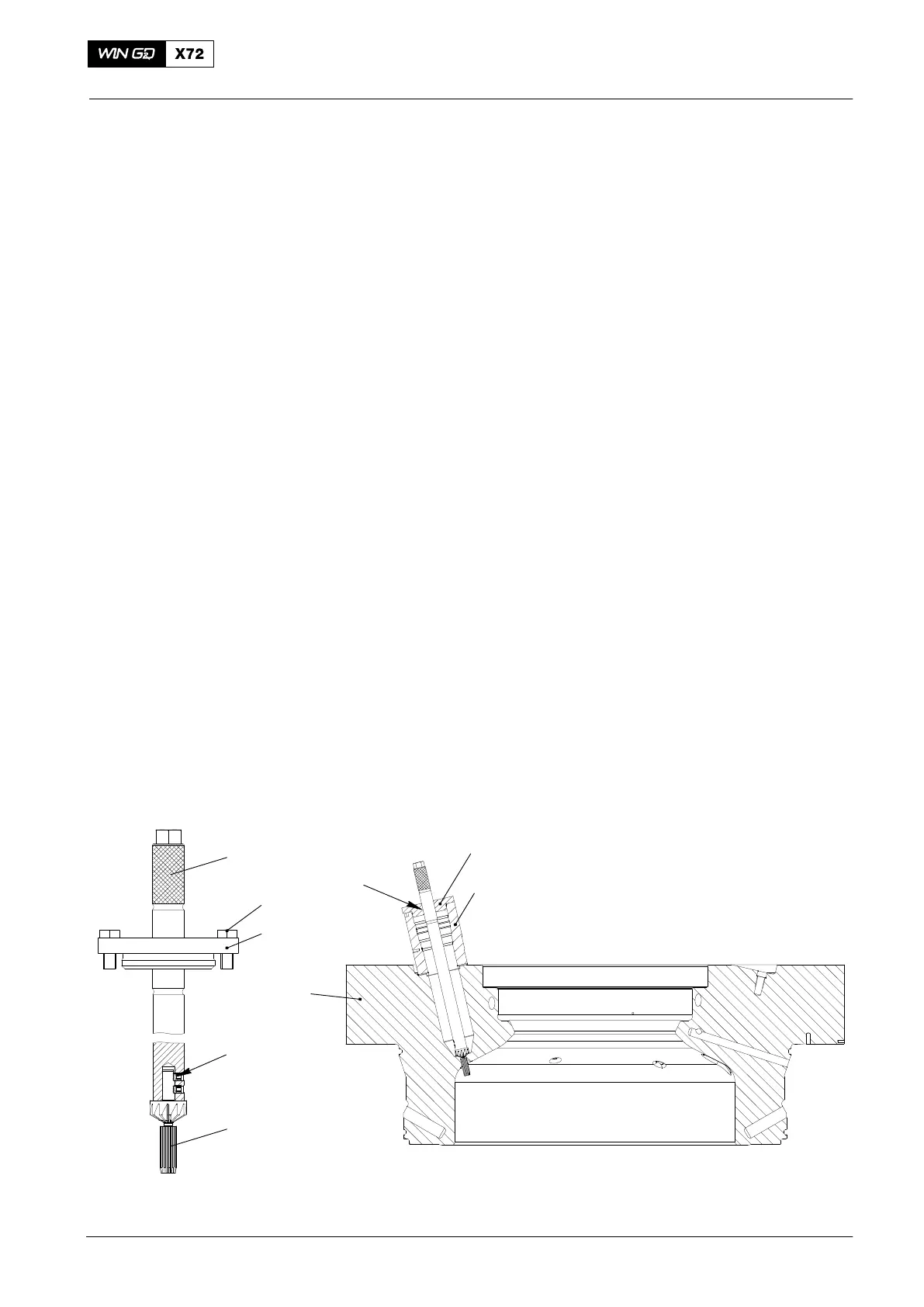

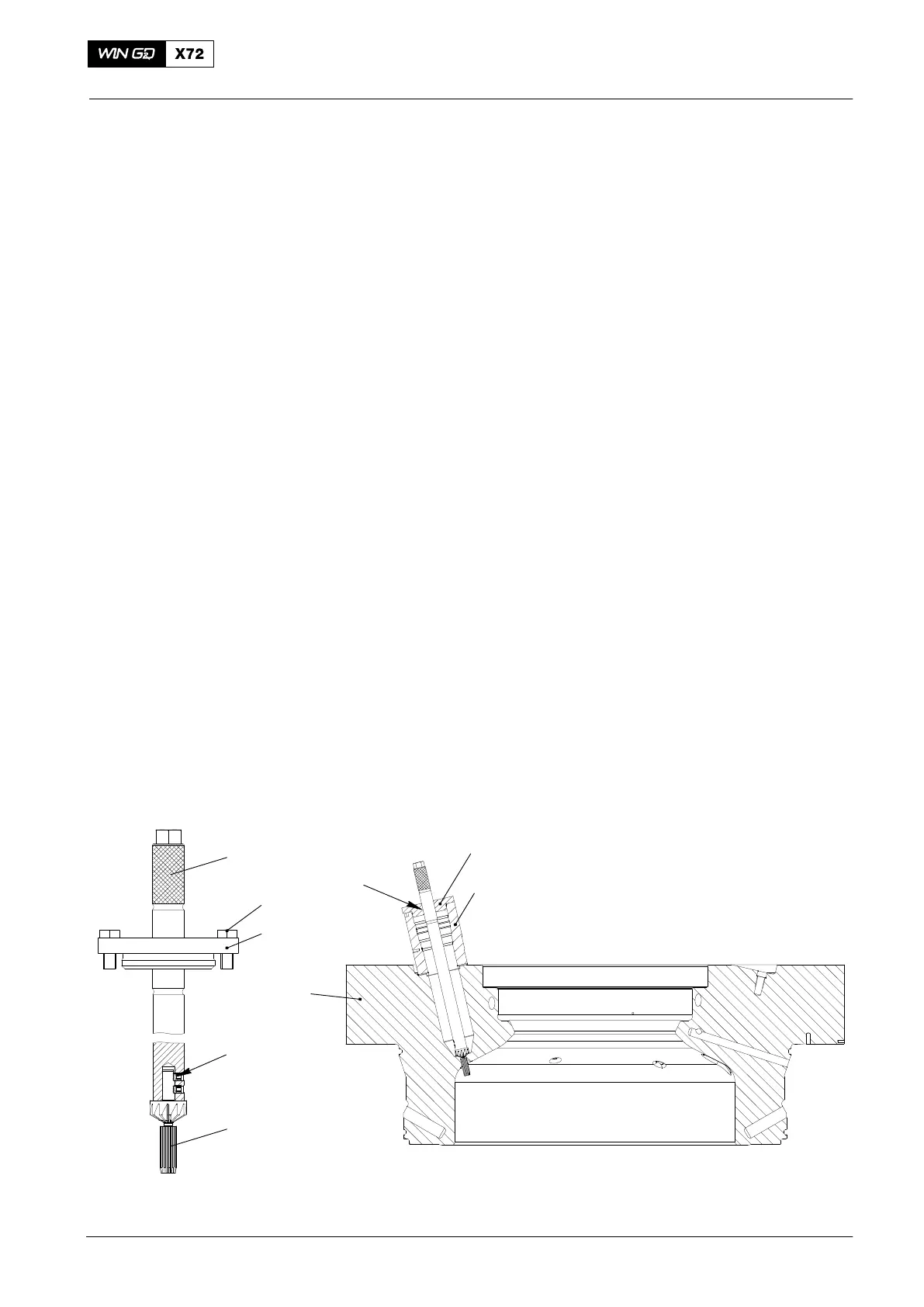

Injection Valve − Sealing Face Machining

Tools:

1 Cutting device 94270

1 Profile cutter 94270A

1 Ring spanner AF24 94000-24

1. General

The sealing face in the cylinder cover is a metallic seal. Thus, this sealing face must

be clean and have no damage.

2. Sealing Face − Machining

For the Fuel Actuated Sacless Technology (FAST) injection valve, you use the cutting

device (94270) to repair sealing faces that are dirty, or have light damage.

1) Apply Molykote G-paste to the running surface (RS, Fig. 1).

2) Apply tacky grease to the profile cutter (94270A). This will make sure that

shavings do not fall into the combustion chamber.

3) Make sure that the two set screws (4) are tight.

4) Carefully put the cutting device (94270) and the profile cutter (94270A) into the

valve bush (2) in the cylinder cover (3).

5) Attach the guide flange (1) to the valve bush (2) with the two screws (5).

6) Put a ring spanner on the top of the cutting device (94270).

7) Push down lightly with your hand on the cutting device (94270) and use the ring

spanner to turn the profile cutter (94270A).

8) Remove only the sufficient quantity of material to get a satisfactory seating area.

WCH02387

94270A

94270

RS

Fig. 1

1

5

4

1

2

3

2015

Cylinder Cover

Loading...

Loading...