Maintenance

5581−1/A1

Winterthur Gas & Diesel Ltd.

3/ 6

2. Bearing Shells −

Removal

1) Loosen the Allen screws (3, Fig. 3) and

remove the filling piece (1) from

bearing cover No.3.

2) Use the pre-tensioning jacks (94557) to

loosen the round nuts (5) of bearing

covers No.1, No.3, No.4 and No.5,

refer to 9403−4.

3) Remove the round nuts (5) and the

bearing covers No.1, No.3, No.4 and

No.5.

4) Put the screwjack (94567B) in position

under the last cam.

5) Turn the screwjack (94567B) to lift the

camshaft between 0.05 mm and

0.15 mm.

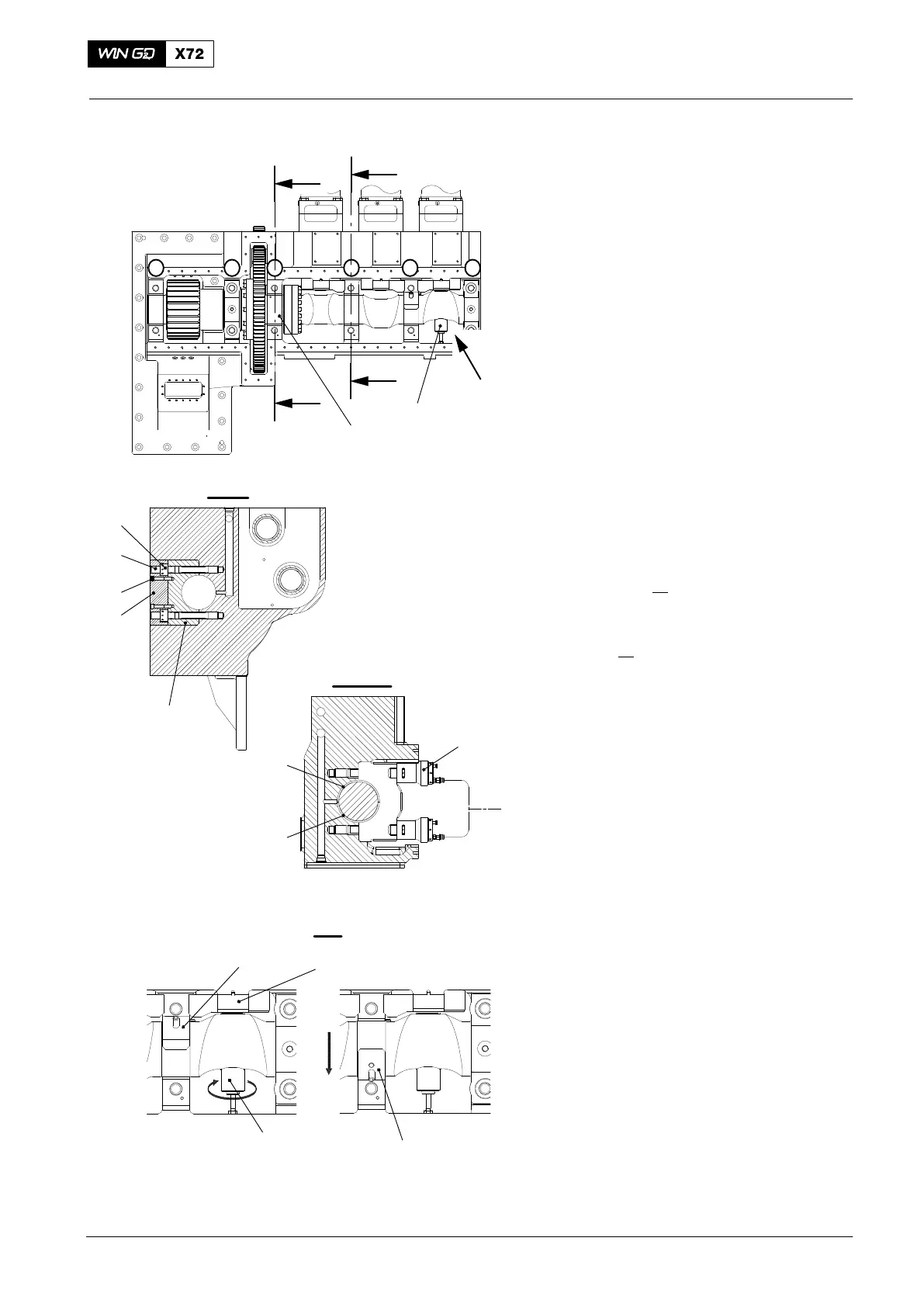

6) Put the tool (94567) in position on the

top bearing shell 14 of bearing No.5

(see View III

).

7) Use the assembly template (94567) to

turn the bearing shells (6, 7), 90° (see

View III

).

Note: If you cannot turn the bearing

shells, adjust the screwjack

(94567B) again.

8) Hold the top bearing shell (7), then

remove the assembly template

(94567).

9) Put marks on the top bearing shells to

identify their positions. This will help

you when you install the bearing shells.

10) Remove the top bearing shell (7).

11) Do step 3) to step 10) to remove the

remaining top bearing shells at

positions No.3 and No.5.

2015

Camshaft and Bearing Shells − Removal and Installation

Fig. 3

6

7

1

2

3

94557

I - I

1 432 5 6

WCH02385

I

I

II

II

I - I

II

94567B

94567

94566B

WCH02385

III

III

94567

4

5

1

94567B

Loading...

Loading...