Maintenance

1132−2/A1

Winterthur Gas & Diesel Ltd.

7/ 14

11) If the value of the lateral bearing clearance is more than 0.1 mm, lower the

crankshaft and do step a) to step c):

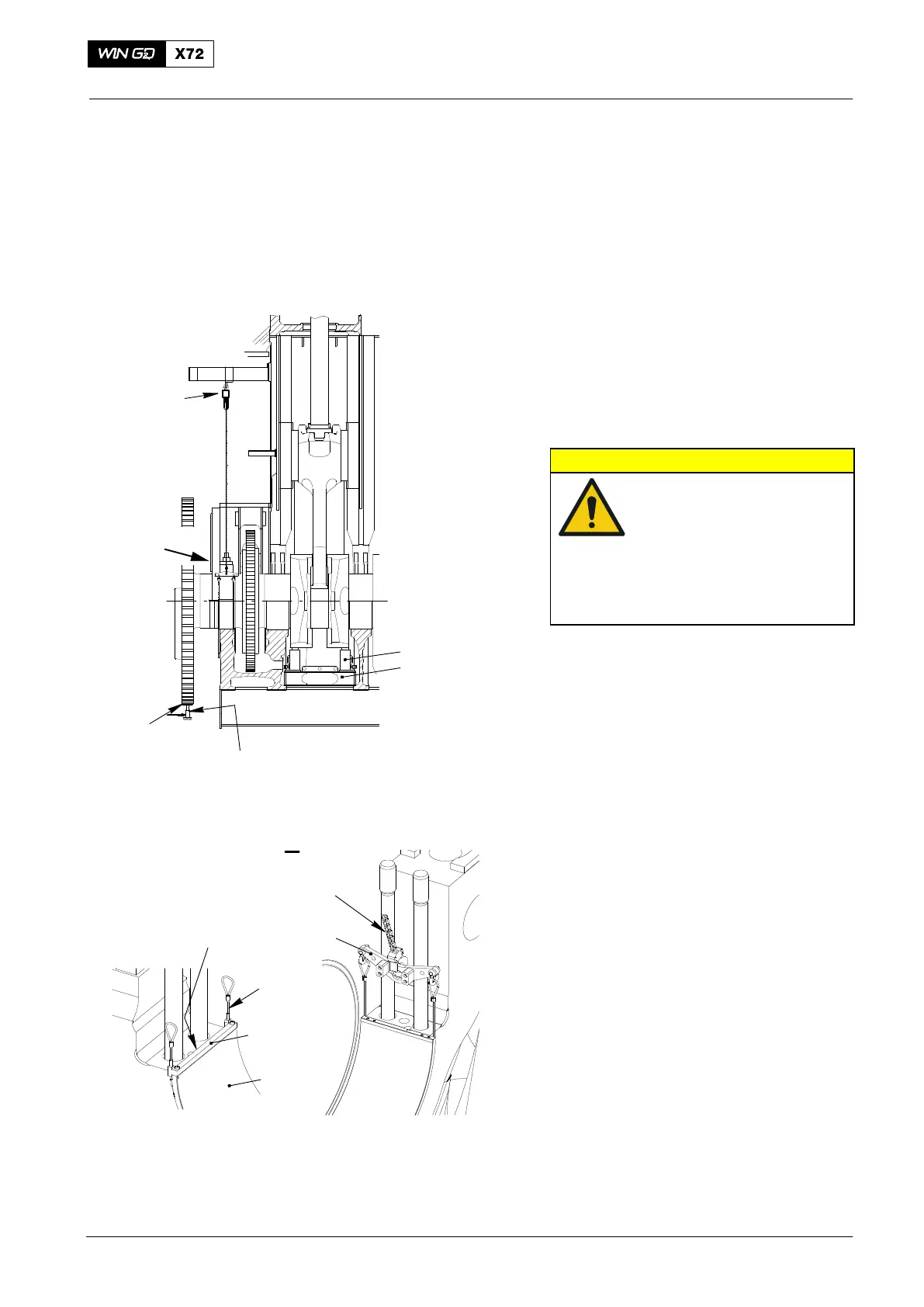

a) Install the hydraulic jacks (94936) in position where the lateral bearing

clearance is smaller.

b) Start the HP oil pump (94931).

c) Lift the crankshaft (1, Fig.15) to 0.3 mm.

4.3 Bearing Shell No.1 (narrow)

− Removal

Note: The bearing cover and the top

main bearing shell are removed.

Note: The crank is at the exhaust side at

TDC.

CAUTION

Damage Hazard: During

this procedure, use only

the applicable tools. Do

not attach external

installations. Do not use

the thrust device 94110 for

removal. Damage to

equipment can occur.

1) Make sure that the crankshaft is lifted

to 0.3 mm, refer to paragraph 4.1 and

4.2.

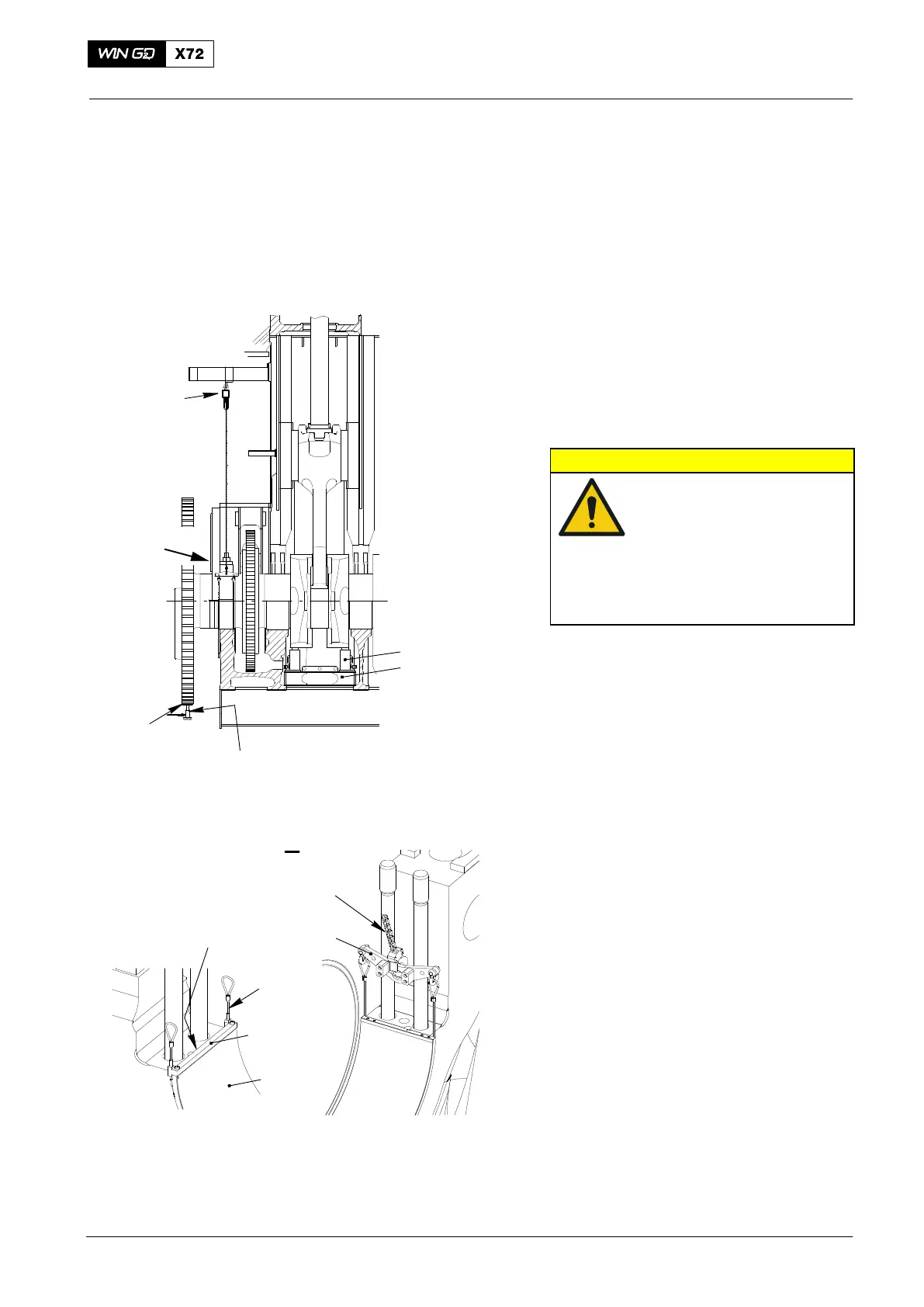

2) Attach the spur-geared chain block

(94017-005) to the eye bolt on the

platform.

3) Remove the Allen screws (1, Fig. 16)

from the bearing girder, see also Fig.

32.

4) Attach the shackle of the spur-geared

chain block (94017-005) to the lifting

plate (94119).

5) Make sure that the shackle of the

spur-geared chain block (94017-005) is

correctly attached to the middle hole of

the lifting plate (94119).

6) Attach the dismantling tool (94118A) to

the bottom main bearing shell (3).

7) Put the ropes (2) along the lateral

edges of the main bearing shell (3) to

the other side and attach them to the

lifting plate (94119) as shown.

2015

Main Bearing − Removal and Installation

94936

94141

1

Protection

I

94017−005

94118A

FUEL SIDE

1

3

EXHAUST SIDE

2

94119

94017−005

I

Fig. 16

Note: Some parts can look

different

Loading...

Loading...