Maintenance1132−2/A1

Winterthur Gas & Diesel Ltd.

6/ 14

4. Main Bearing Shell − Removal

4.1 Hydraulic Jacks − Installation

WARNING

Injury Hazard: Before you operate the turning gear, make sure

that no personnel are near the flywheel or in the engine.

CAUTION

Damage Hazard: Do not remove two adjacent main bearing shells

at the same time. Damage can occur to the bearing shells.

1) Operate the turning gear to turn the

crank to the exhaust side

approximately 90_ after TDC.

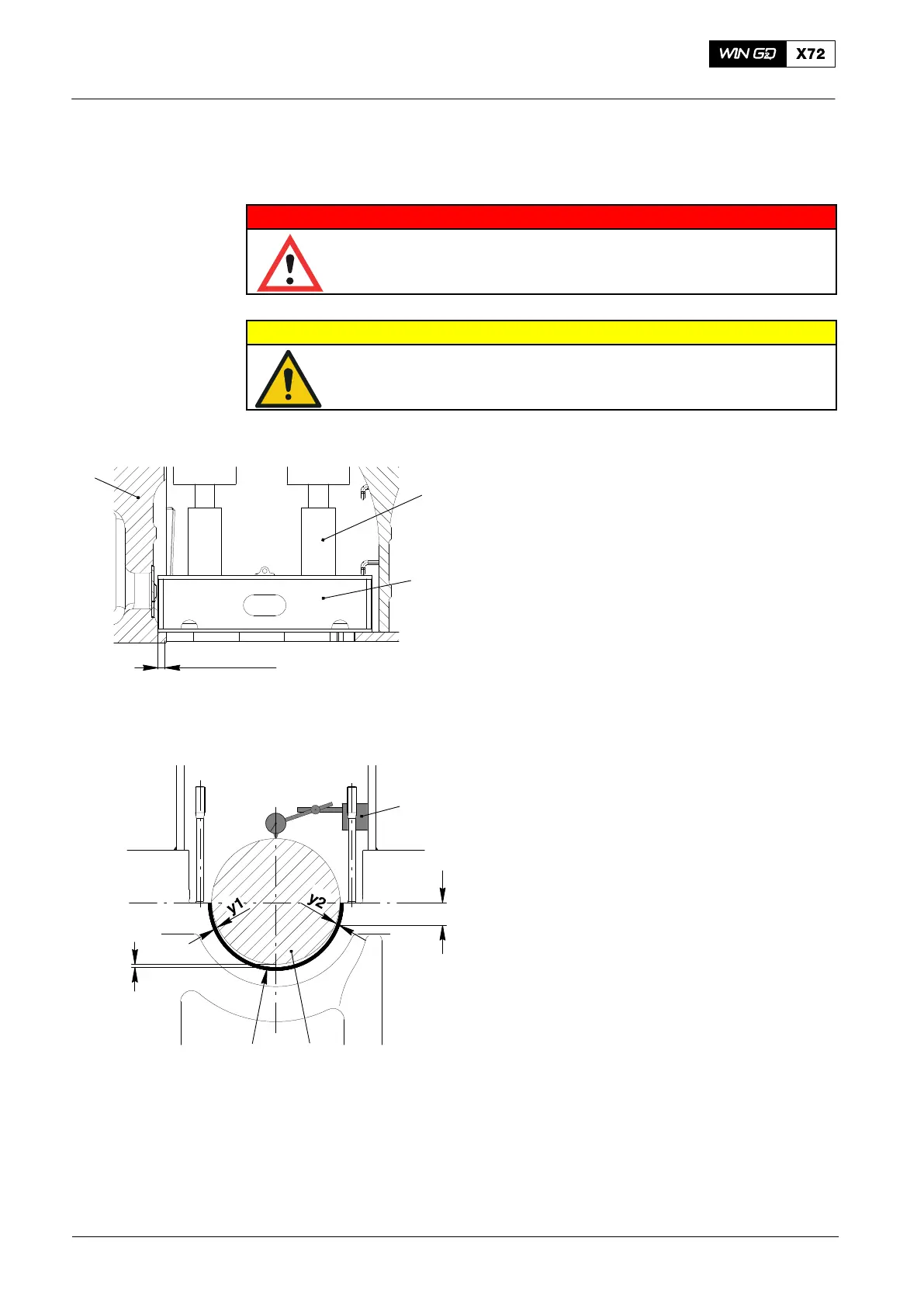

2) Put the bracket (94141A, Fig.14) on the

two main bearing girders (1) parallel to

the engine axis.

3) Make sure that the bracket is a

minimum of 43 mm from the thrust

bearing side.

4) Put the hydraulic jacks (94936) on the

bracket (94141A).

5) Connect the hydraulic jacks (94936) to

the HP oil pump (94931), refer to

9403−2.

4.2 Crankshaft − Lift

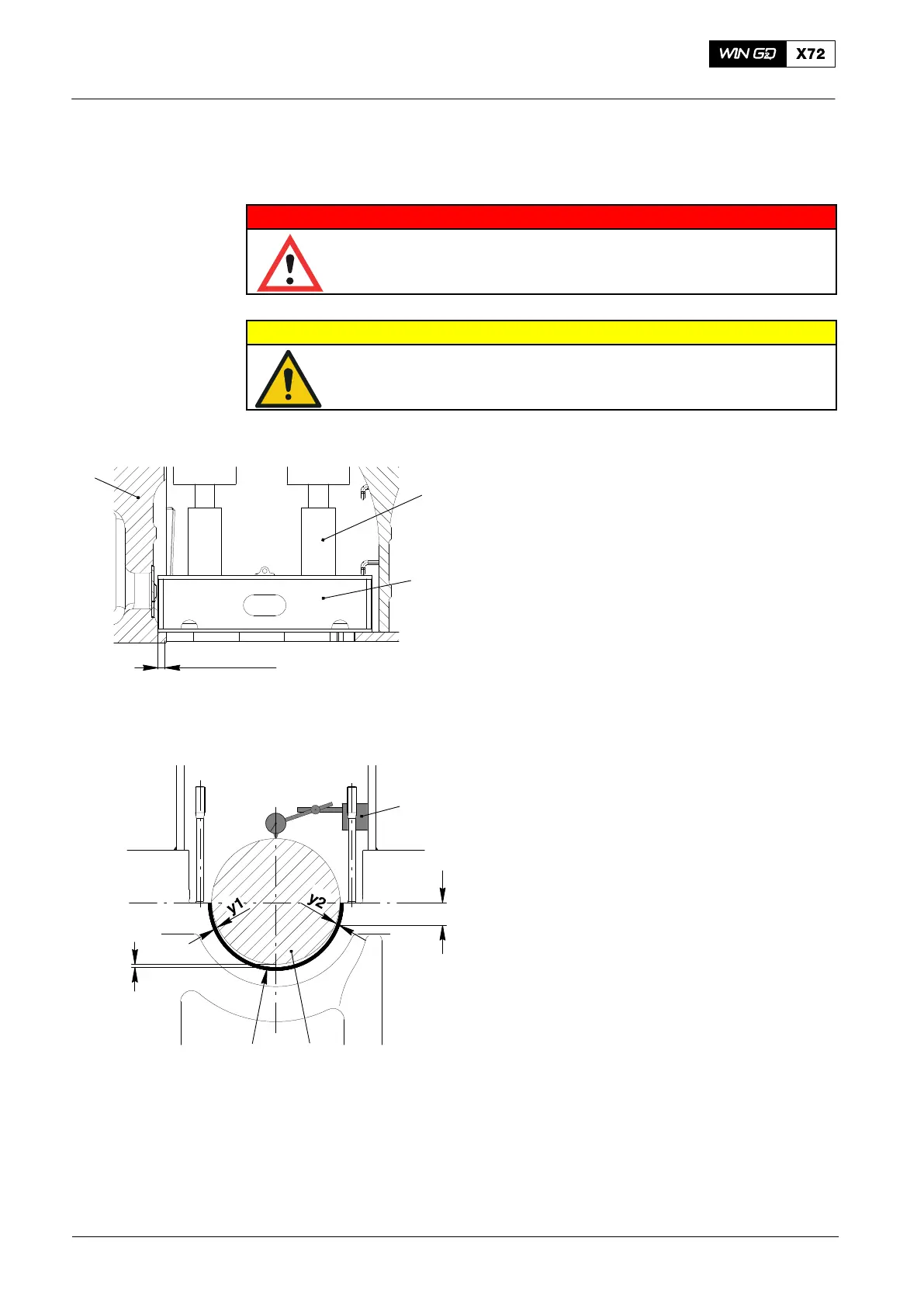

1) Record the values of the lateral

clearances (y

1

and y

2

, Fig.15) between

the crankshaft (2) and the bottom main

bearing shell (3,4) at approximately

50 mm below the bearing.

2) Install the dial gauge (1) above the

crankshaft (2) as shown

3) Set the dial gauge (1) to zero.

4) Install the jacks (94936).

5) Start the HP oil pump (94931).

6) Operate the hydraulic jacks (94936) to

lift the crankshaft (2) to 0.3 mm.

7) Make sure that the value on the dial

gauge is 0.3 mm.

8) Make sure that there is no clearance

between the adjacent bearing cover

and the crankshaft.

9) Keep the pressure constant.

10) Measure the lateral bearing clearances

y

1

and y

2.

Compare these values with

the values recorded in step 1).

2015

Main Bearing − Removal and Installation

WCH02332

94936

94141A

1

min. 43 mm

0.3mm

50 mm

009.810/02

1

23,4

Fig. 14

Fig. 15

Loading...

Loading...