Maintenance

4325−1/A1

Winterthur Gas & Diesel Ltd.

1/ 6

Cleaning and Function Check

1. General 1..........................................................

2. Preparation 1.......................................................

3. Disassembly 2.....................................................

4. Servicing 2.........................................................

5. Assembly 4........................................................

6. Shut-off valve test 5................................................

6.1 Initial position 5..............................................

6.2 Test procedure 5..............................................

6.3 Automatic mode 7............................................

7. Completion 7.......................................................

1. General

Read the data in 0380−1, Starting air shut-off valve for the necessary maintenance

and intervals on the shut−off valve for starting air (shut-off valve).

See the data in the Operation Manual 4003−2, Engine Control Diagram and 4003−9,

Pipe Diagram − Air Systems.

2. Preparation

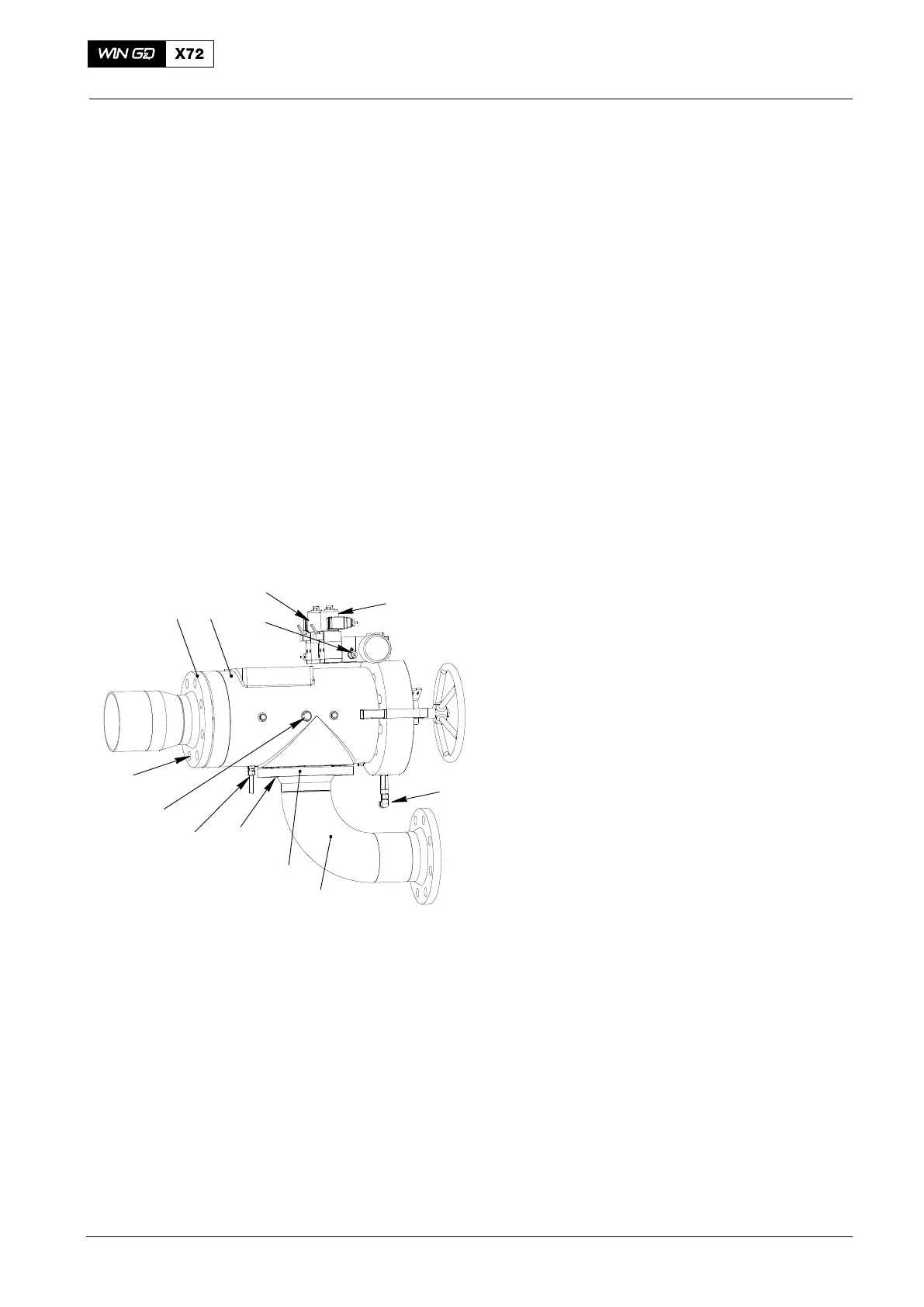

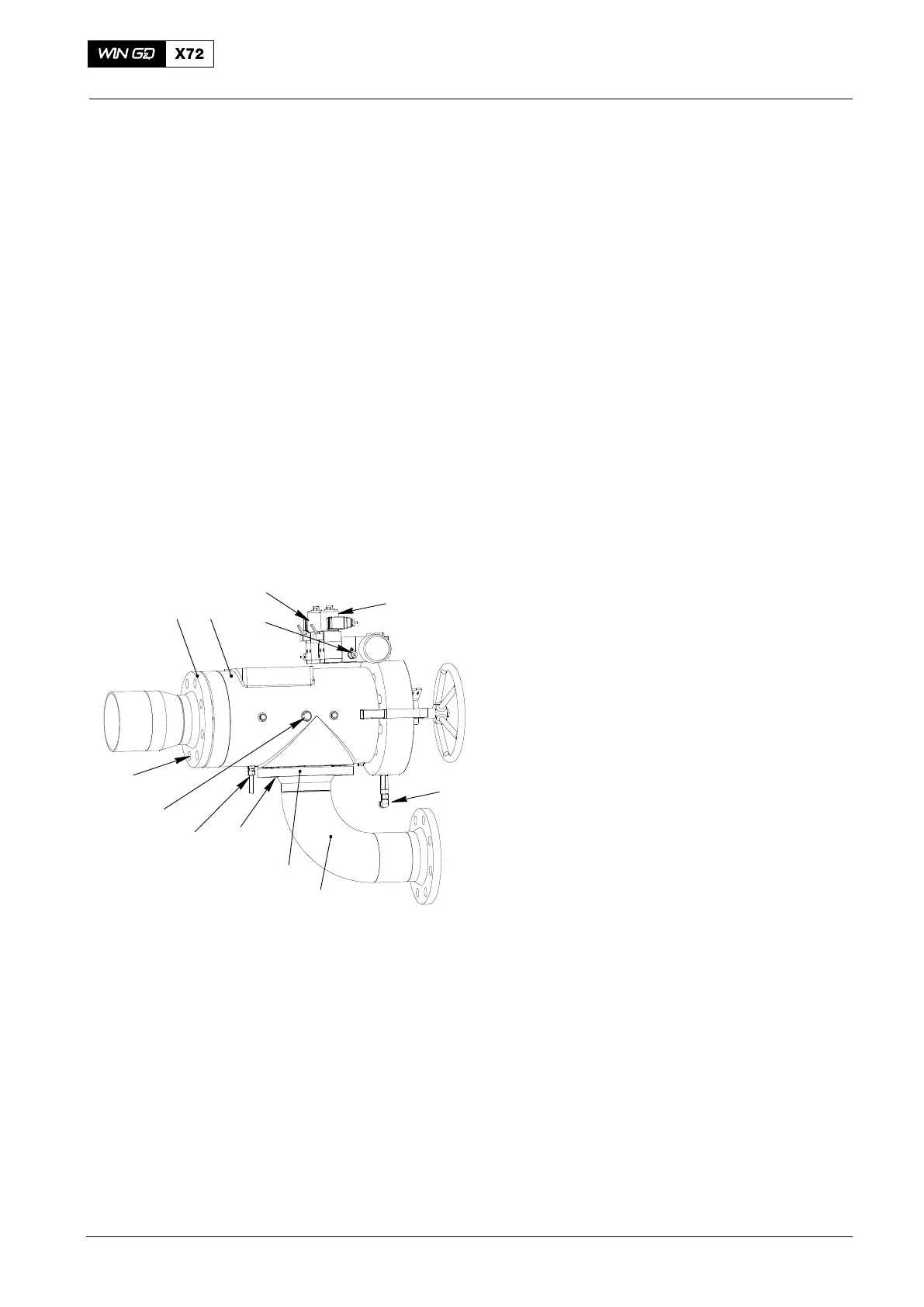

1) On the starting air bottles, close the

stop valves 930−V03 and 930−V04.

2) Engage the turning gear.

3) Open the ball valves 30−8605_EO_7

and 30−8605_EO_8 to release air in

the system.

4) Disconnect the electrical connections

from the pressure transmitter (24,

Fig. 1) and the solenoid valves (1 and

8).

5) Remove the pipe (2).

6) Remove the pipe (35).

7) Remove the eight screws (6) from the

flange (7).

8) Remove the eight screws (4) from the

flange (3).

9) Remove the shut-off valve from the

engine.

10) Do a check of the two gaskets that are

installed on the flanges (3 and 7). if the

gaskets are unserviceable, replace

them.

2015

Shut-off Valve for Starting Air

7

4

6

3

2

35

5

1

8

WCH02404

24

33

Fig. 1

9

Loading...

Loading...