Maintenance

3403−1/A1

Winterthur Gas & Diesel Ltd.

1/ 6

Removal and Installation

Tools:

1 Lifting tool 94209 1 Piston suspension device 94341

2 Distance holders 94230 1 Insertion funnel 94342

2 Pre-tensioning jacks 94340 1 Piston support device 94350

1 Cover plate 94345D

1. Preparation 1.......................................................

2. Removal 3.........................................................

3. Installation 4.......................................................

1. Preparation

WARNING

Injury Hazard: Before you

operate the turning gear,

make sure that no

personnel are near the

flywheel, or in the engine.

1) Stop the engine, see the procedure in

Operation Manual 4002−2.

2) Let the engine temperature decrease

before you start the removal procedure.

3) Make sure that all tools and equipment

are clean.

4) Remove cylinder cover, refer to

2708−1.

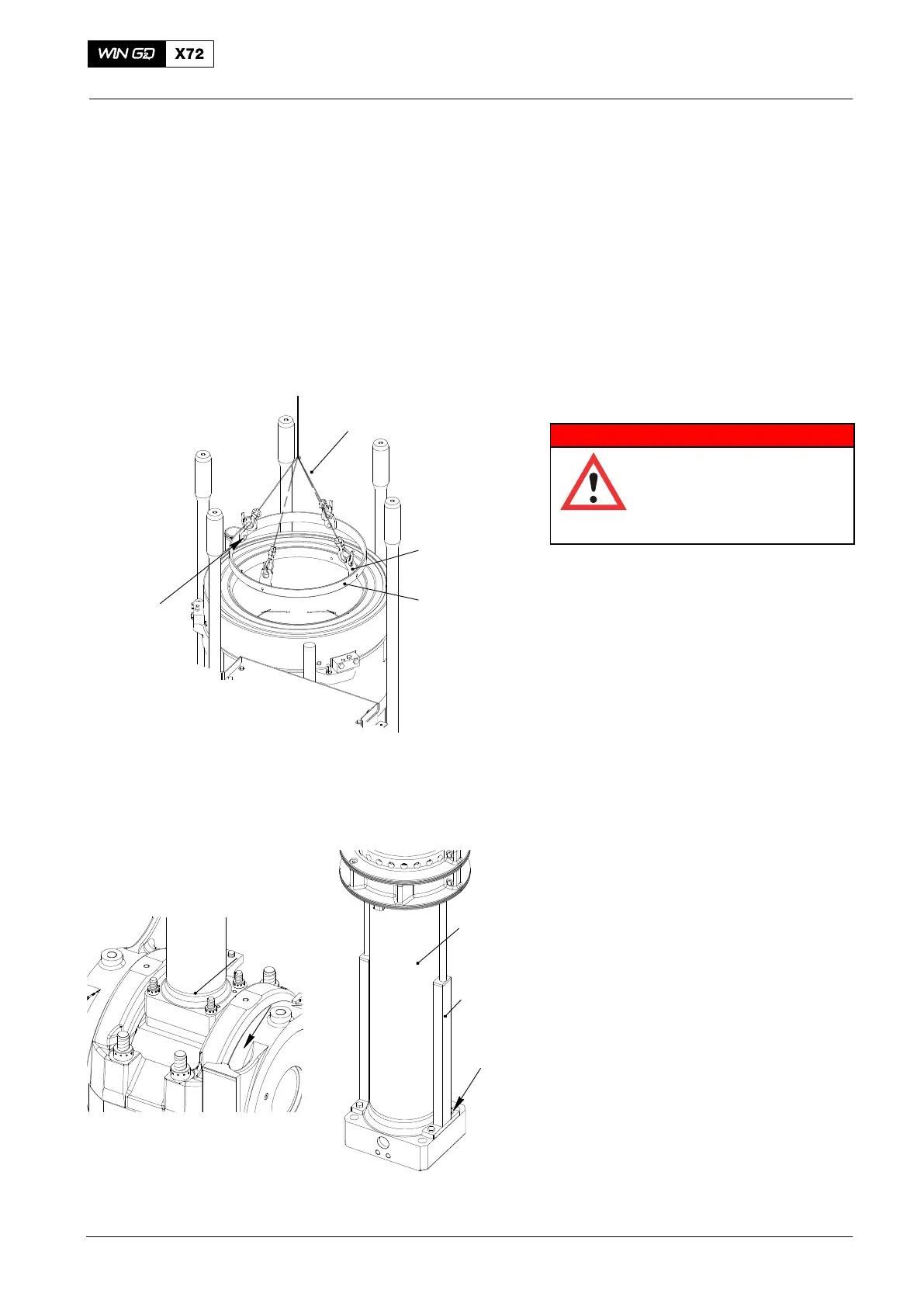

5) Attach the four plates (1, Fig. 1) of the

lifting tool (94209) to the anti-polishing

ring (2) with the four screws (3).

6) Connect the crane hook to the lifting

tool (94209).

7) Attach the lifting tool (94209) to remove

the antipolishing ring (2).

8) Remove the antipolishing ring.

9) Look at the area of the piston ring

stroke. If there is a wear ridge, refer to

the procedure in 2124−3

10) Operate the turning gear to turn the

crank to BDC.

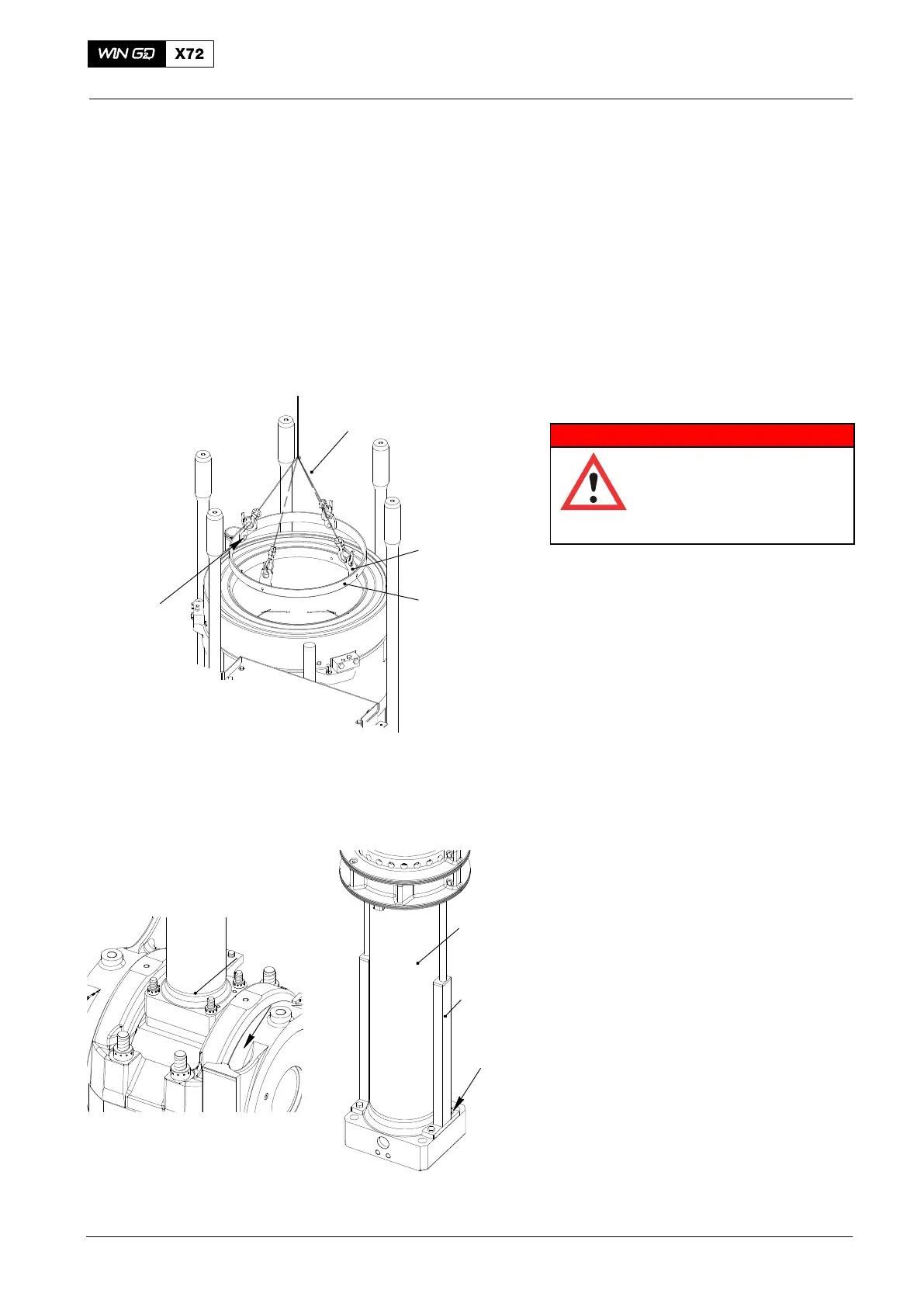

11) Loosen the four round nuts (3, Fig. 2)

the piston rod foot, refer to the

procedure given in 9403−4 .

12) Remove the four round nuts (5).

13) Attach the two distance holders

(94230) to the piston rod foot with the

four screws (2).

2015

Piston

Fig. 1

Fig. 2

94230

WCH02460

1

3

1

2

1

2

3

94209

WCH02609

Loading...

Loading...