Maintenance1112−1/A1

Winterthur Gas & Diesel Ltd.

2/ 2

2. Tension Check

1) Clean the threads of the foundation bolts (6, Fig.3) and the seating surfaces.

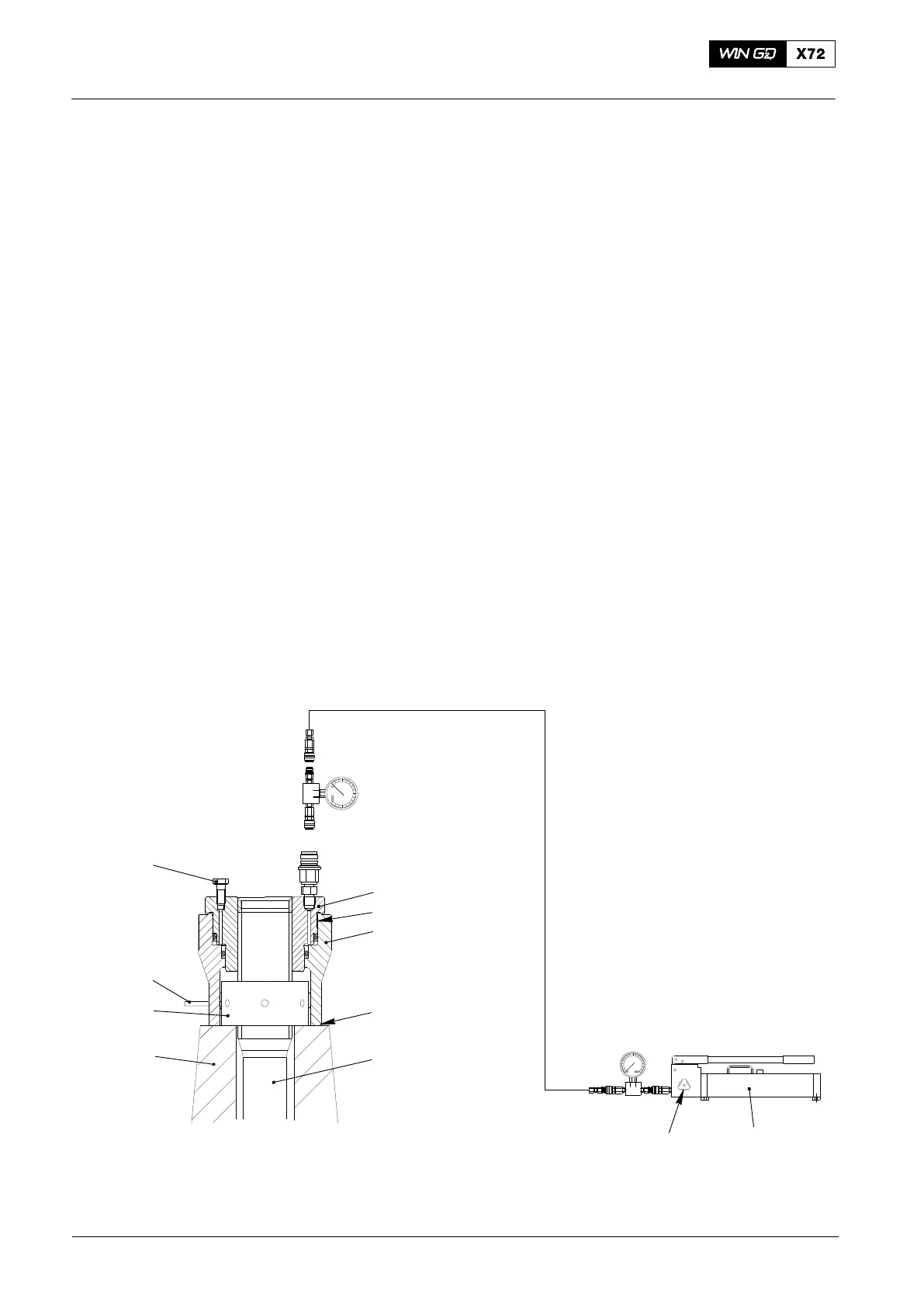

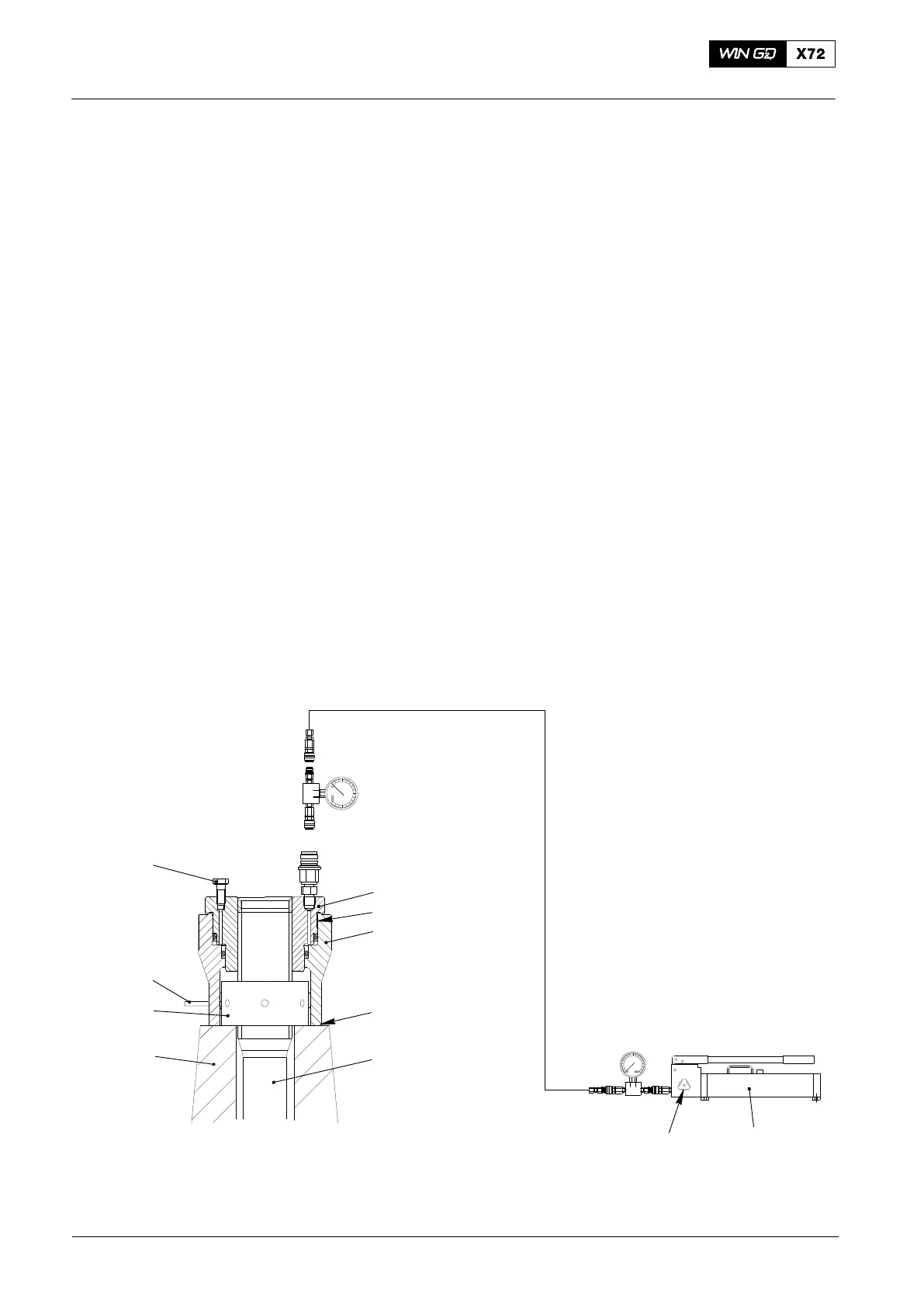

2) Attach the pre-tensioning jack (94145, Fig.1) to the foundation bolt (6, Fig.3).

3) Open the vent screw (1).

4) Turn the foundation bolt (6) fully down until there is a small clearance, or no

clearance between the foundation bolt and the nut (4).

5) Connect the pre-tensioning jack (94145) to the HP oil pump (94931), refer to

9403−3.

6) Close the relief valve (RV).

7) Operate the HP oil pump (94931) until oil that has no air flows from the vent

screw (1).

8) Close the vent screw (1).

9) Torque the foundation bolt (6) to 1500 bar and keep the pressure constant.

10) Do not move the piston (3) of the pre-tensioning jack (94145) to more than the

red limit groove (LG).

11) Put the feeler gauge (94122) through the slot (8). Do a check for clearance

between the nut (4) and the bush (7). If you find a clearance do step a) a step b).

a) Keep the pressure of 1500 bar.

b) Use the round bar (RB) to fully tighten nut (4).

12) Decrease the pressure to zero.

13) Remove the pre-tensioning jack (94145).

RB

8

6

3

94931

012.949/05

2

4

7

LG

1

016.704/08

RV

Fig. 3

Foundation Bolts − Check

2015

Loading...

Loading...