Maintenance

1112−1/A1

Winterthur Gas & Diesel Ltd.

1/ 2

Foundation Bolts Checks

Tools:

1 Feeler gauge 94122 2 Hydraulic distributors 94934A

1 Pre-tensioning jack 94145 1 HP hose 94935

1 HP oil pump 94931

1. General

You must do a check of the tension of the foundation bolts (hold-down studs) at

longer intervals e.g. during overhauls refer to 0380−1, Bedplate.

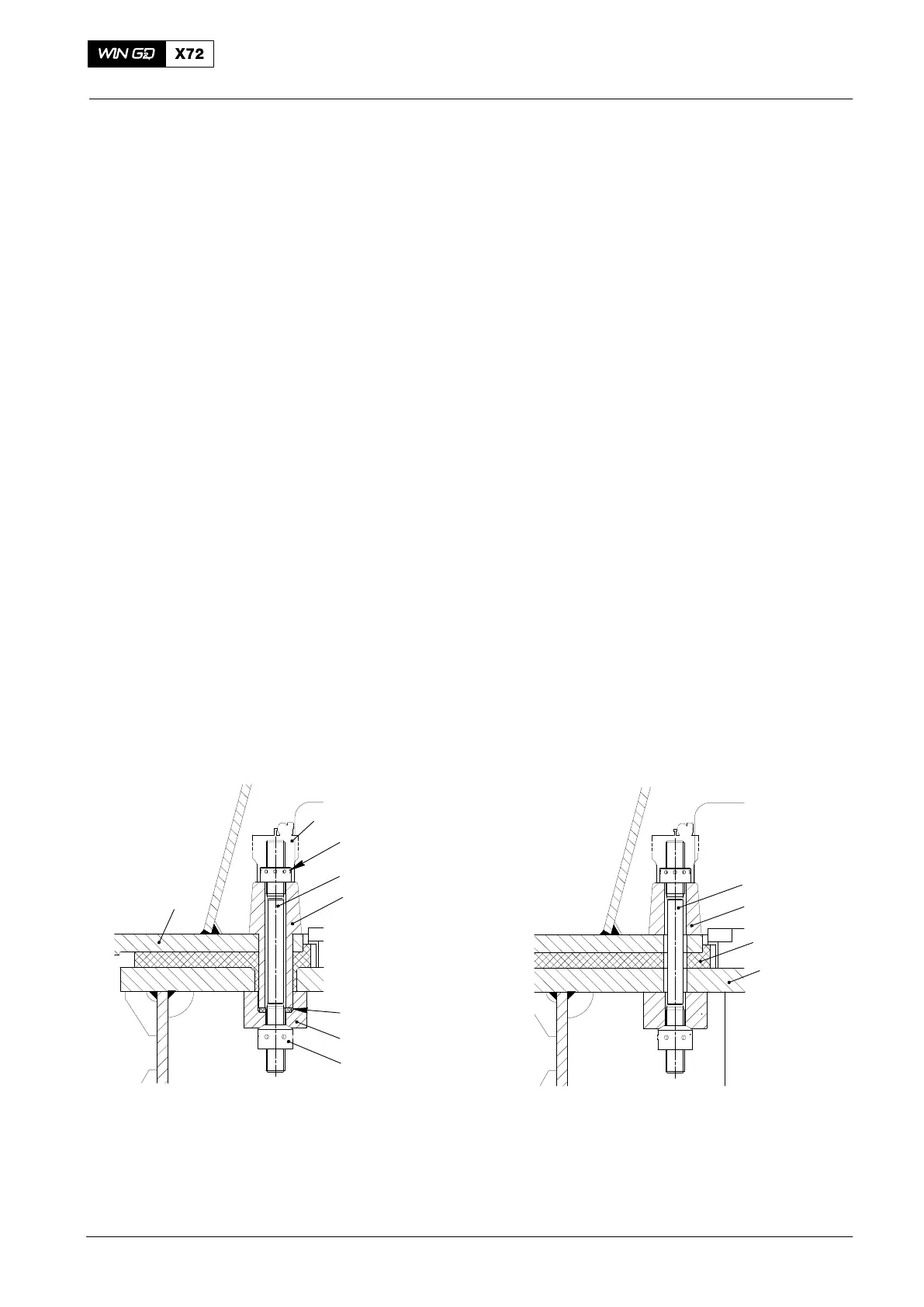

In the area of the thrust bearing, the bedplate (5, Fig.1) and the foundation must be

attached with foundation bolts (6) and the long bushes (7).

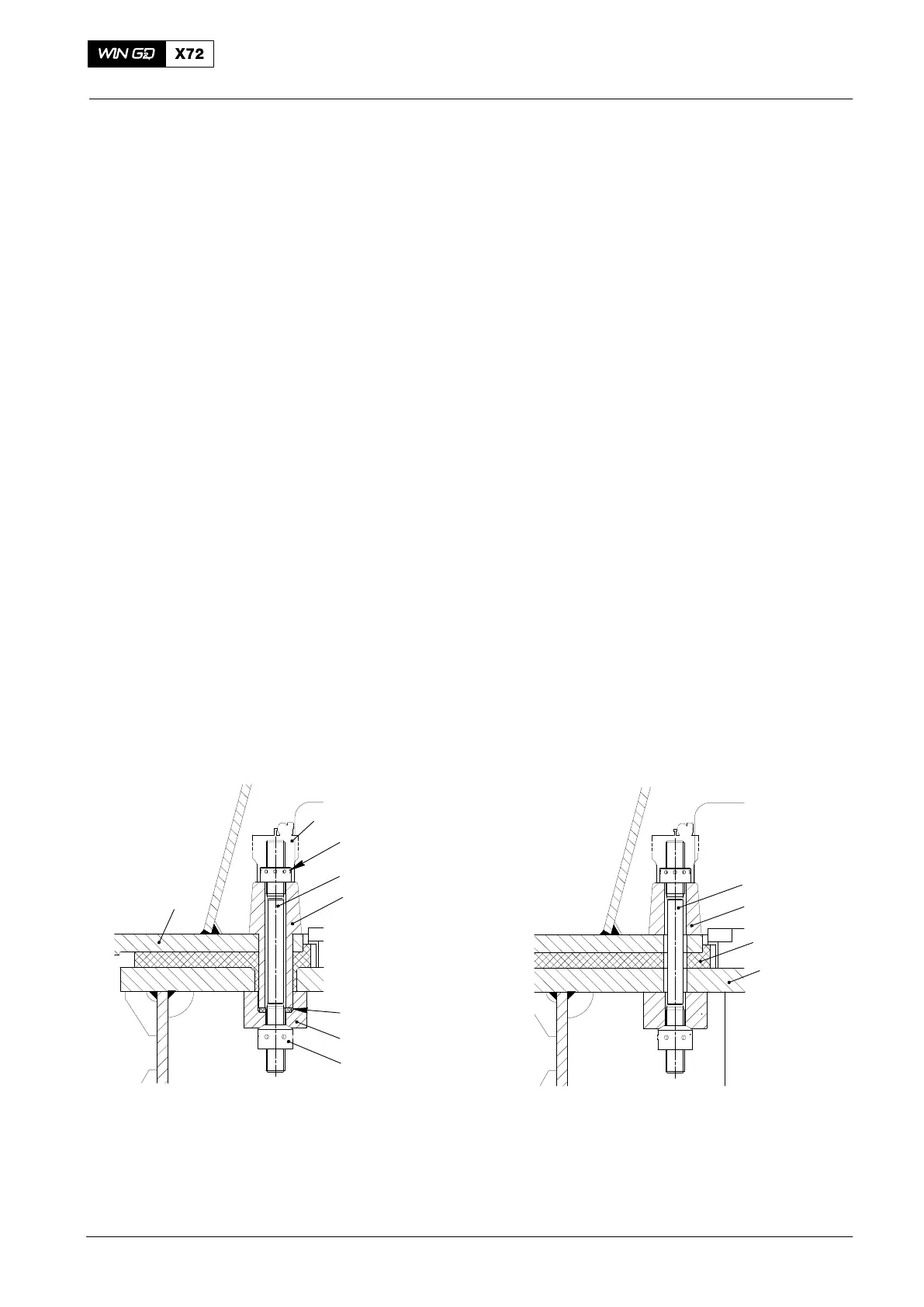

The remaining area is attached with the foundation bolts (6, Fig.2) and the short

bush (7a).

1.1 Foundation Bolts − Loosen or Apply Tension

You start the procedure to apply tension to the foundation at the driving end, and from

one side to the other. The procedure is completed at the free end.

1) To loosen and apply tension to the foundation bolts (6), use the pre-tensioning

jack (94145, Fig.1).

2) Connect the pre-tensioning jacks (94145) to the hydraulic pump (94931, Fig.3),

refer to 9403−3.

3) Do the Version 1 procedure as given in 9403−4.

4) Apply tension in two steps as follows:

a) Step 1 − For metal chocks or epoxy resin chocks, i.e. first apply tension to all

foundation bolts to 1000 bar.

b) Step 2 − Apply tension to 1500 bar.

7

11

10

4

6

5

7a

6

9

12

WCH02319

8

Fig. 1

Fig. 2

94145

Bedplate and Thrust Bearing

2015

Loading...

Loading...