Maintenance4103−2/A1

Winterthur Gas & Diesel Ltd.

2/ 6

2. Preparation

4

1

9

5

3

9

6

WCH02403

4

5

d

I

I

I

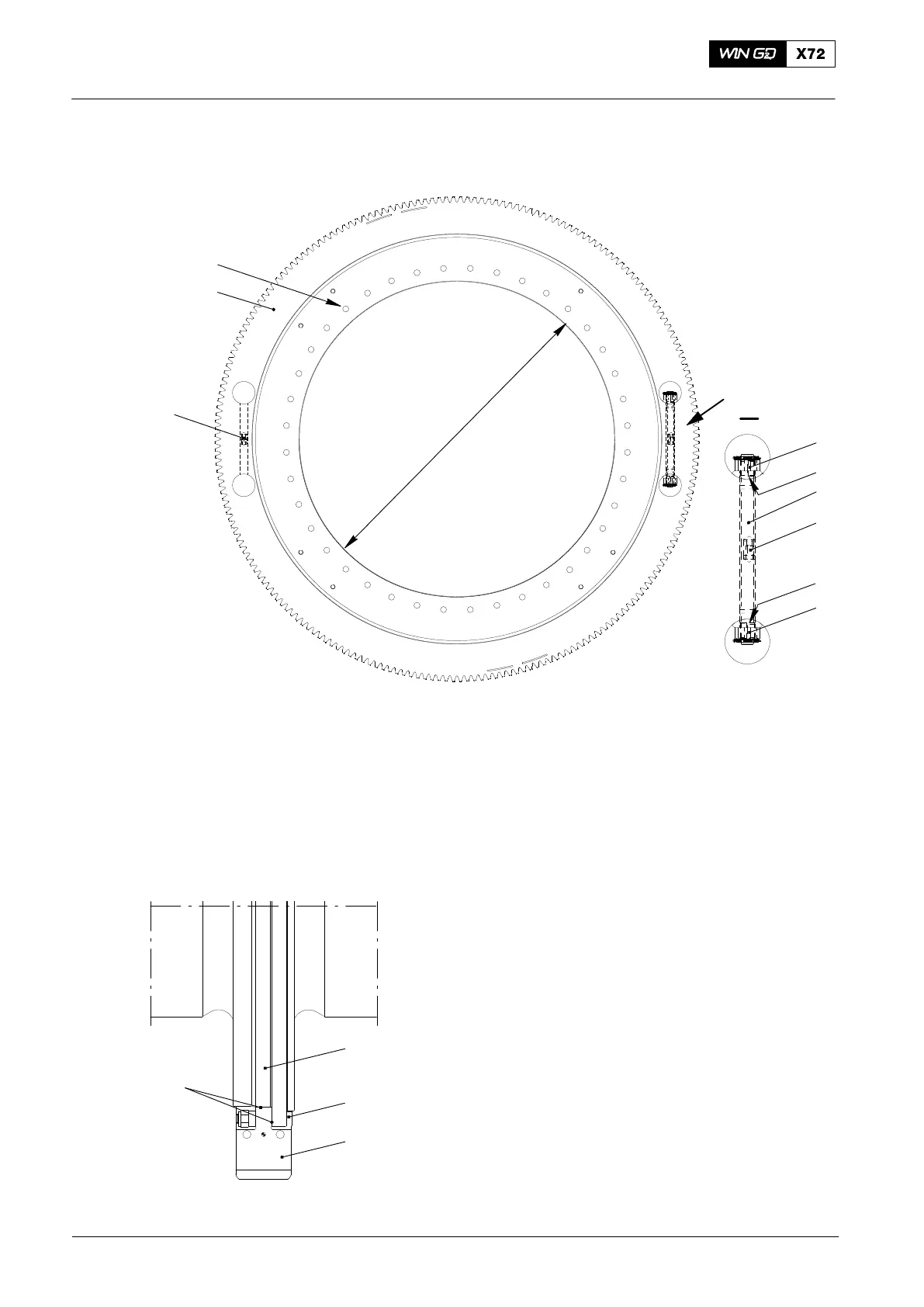

Fig. 1

1) Make sure that the temperature of the crankshaft, the gear wheel and the tool to

measure the dimensions is the same.

2) Measure and record the inner diameter (d, Fig. 1) of the two-part gear wheel (1).

3) Measure and record the outer diameter of the crankshaft.

4) The inner diameter of the crankshaft gear wheel must be between 0.05 mm and

0.14 mm less than the outer diameter of the crankshaft.

Note: The nominal diameter of the crankshaft flange is 1670 mm.

5) If the value is not as given in step 4),

do as follows before you assemble the

gear wheel:

a) Use the applicable equipment and

processes (e.g. mill, or ream the

bore etc) to get the inner diameter

to the correct dimension.

b) Make sure that there is a mark on

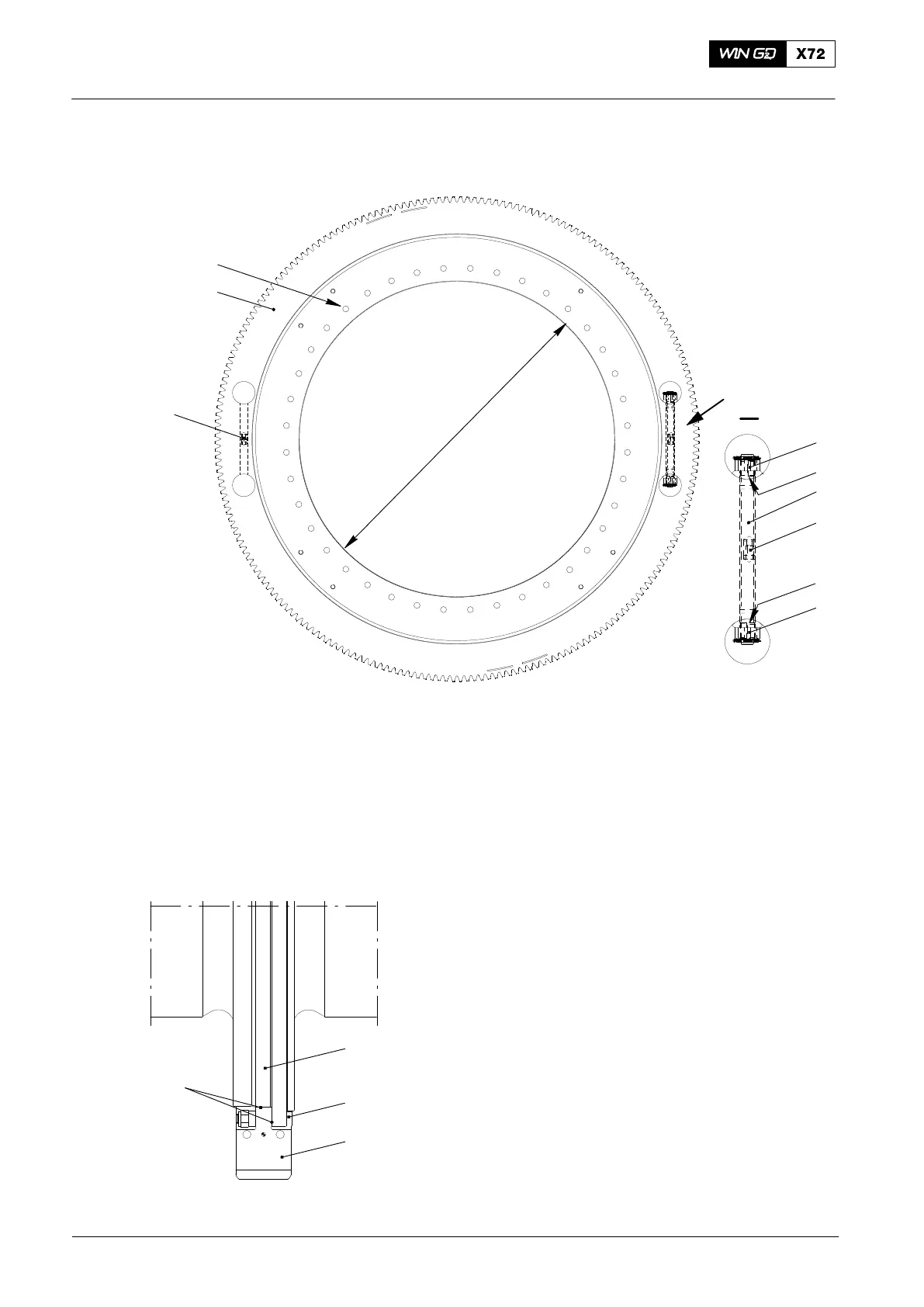

the crankshaft flange (2, Fig. 2).

During the assembly procedure,

the partition of the crankshaft gear

wheel must align with this mark.

2015

Replacing the Gear Wheel on the Crankshaft

2

DRIVING

END

Remove

Grease

6

Fig. 2

1

WCH02403

Loading...

Loading...