Maintenance

5562−2/A1

Winterthur Gas & Diesel Ltd.

1/ 3

Removal, Check, Installation

Tools:

1 OBEL test bench 94272 2 Pressure gauge 94934A

1 Valve holder 94272A 2 HP hoses 94935

1 HP oil pump 94931

1. General

Maintenance of the relief valve (1, Fig. 1) is not usually necessary, but you must do a

function check at regular intervals. Refer to the Maintenance Schedule 0380−1 Relief

Valve for the frequency to do the function test. Unserviceable relief valves must be

sent to the manufacturer, or a WinGD authorized repair workshop for inspection and

repair.

The International Association of Classification Societies (IACS) approval is given for:

D The type of test

D The type of certificate

D The frequency of the test.

The results of the test must be recorded in the Inspection Report.

Note: The two bores (2) identify the relief valve (1) as a new item.

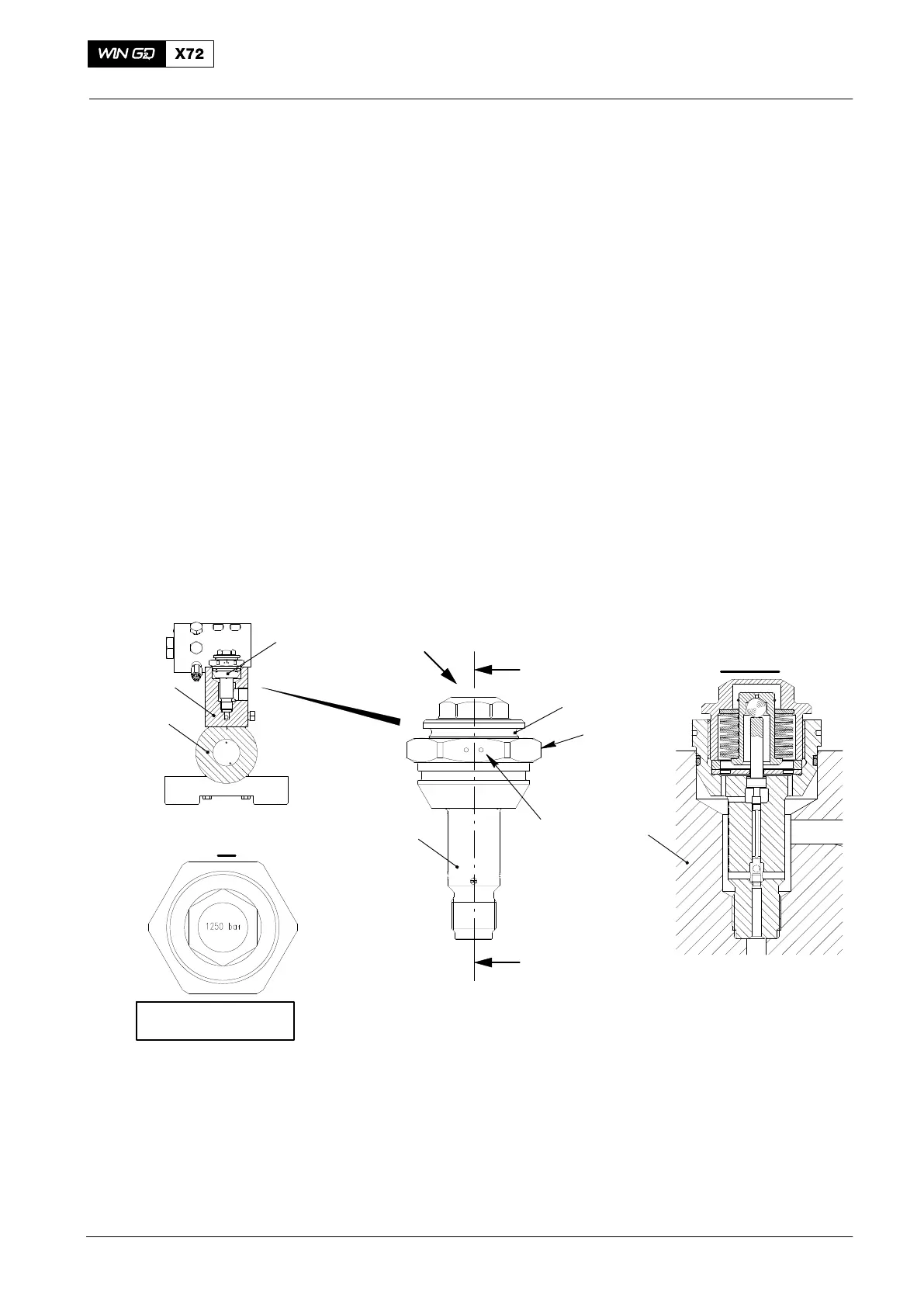

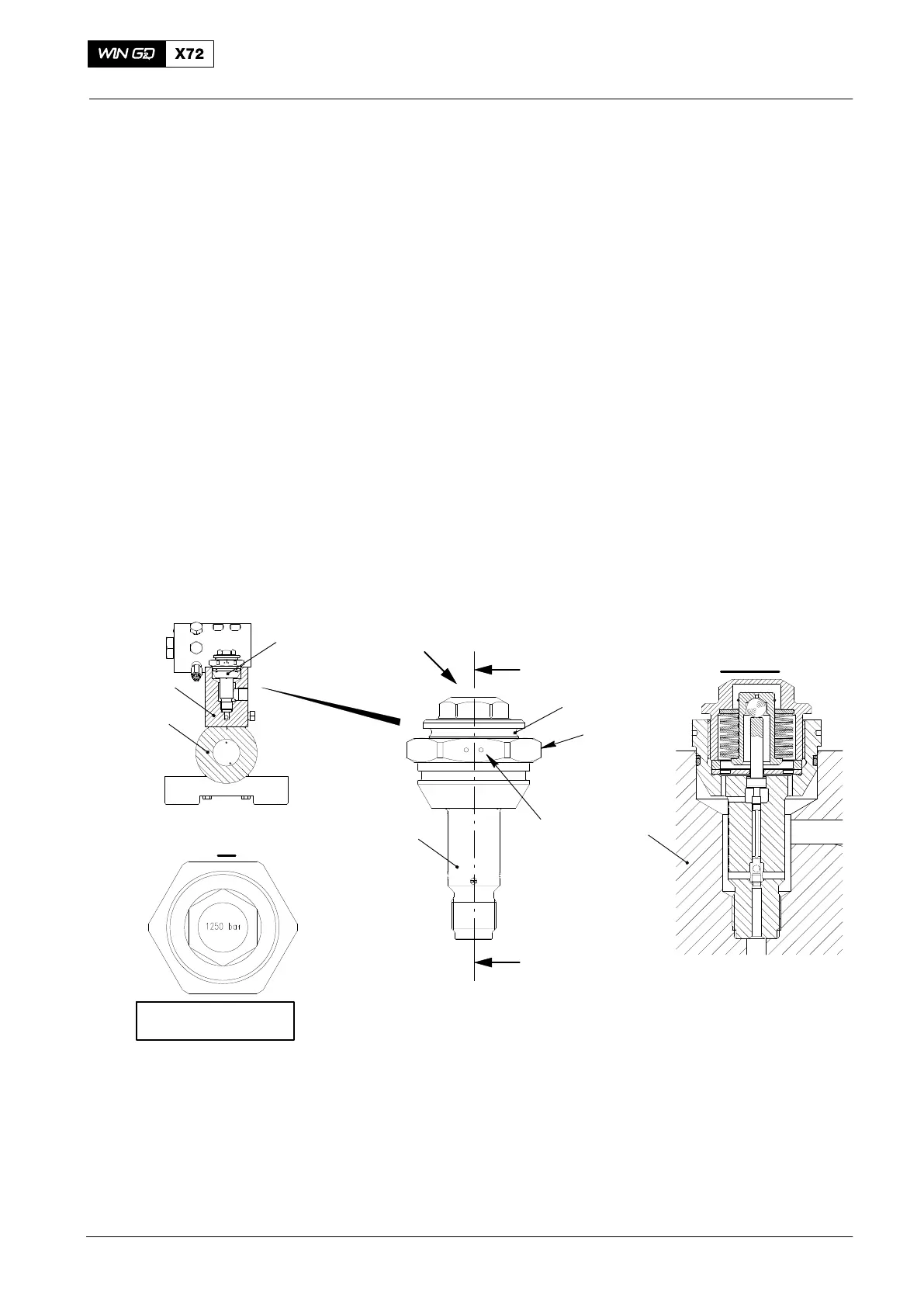

Fig. 1

4

1

Fuel Rail

Applicable pressure that

opens the relief valve

I

1

AF80

2

3

I

II

II

II - II

4

WCH03213

WCH03213

WCH03213

2. Removal

1) Stop the engine (refer to the Operation Manual 0310−1).

2) Make sure that the fuel rail has no pressure.

3) Use a spanner (AF80) to remove the relief valve (1) from the valve block (4).

Relief Valve

2015

Loading...

Loading...