Maintenance0352−2/A1

Winterthur Gas & Diesel Ltd.

2/ 3

2. Replacement of Elastic Studs

2.1 Procedure

1) Read the data in the manual of the jointing compound manufacturer.

2) Remove the unserviceable elastic stud.

3) Remove the grease and clean the sealing surfaces of the new elastic stud.

4) Remove the grease and other unwanted material from the tap hole and the area

where the elastic stud will be installed.

5) Clean the tap hole and the area where the elastic stud will be installed.

6) If necessary, apply an adhesive primer to the shank of the elastic stud. Make

sure that no adhesive primer goes on to the threads.

7) Use only a stud driver (or two nuts locked together) to fully install the stud into the

tap hole.

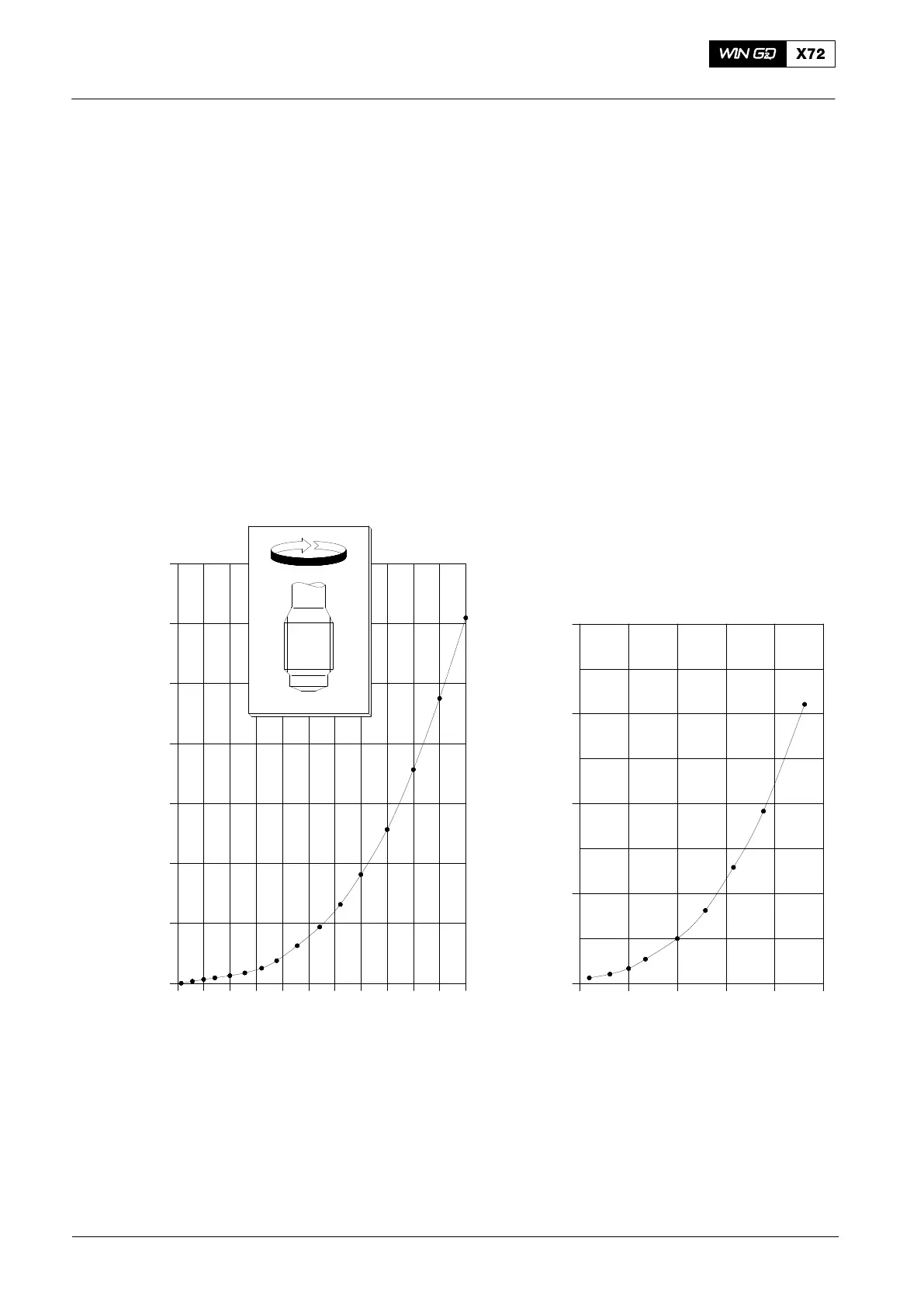

8) Torque the elastic stud to the applicable value given in the table below:

TORQUE [Nm]

400

300

200

10

100

20 30 40 50 60

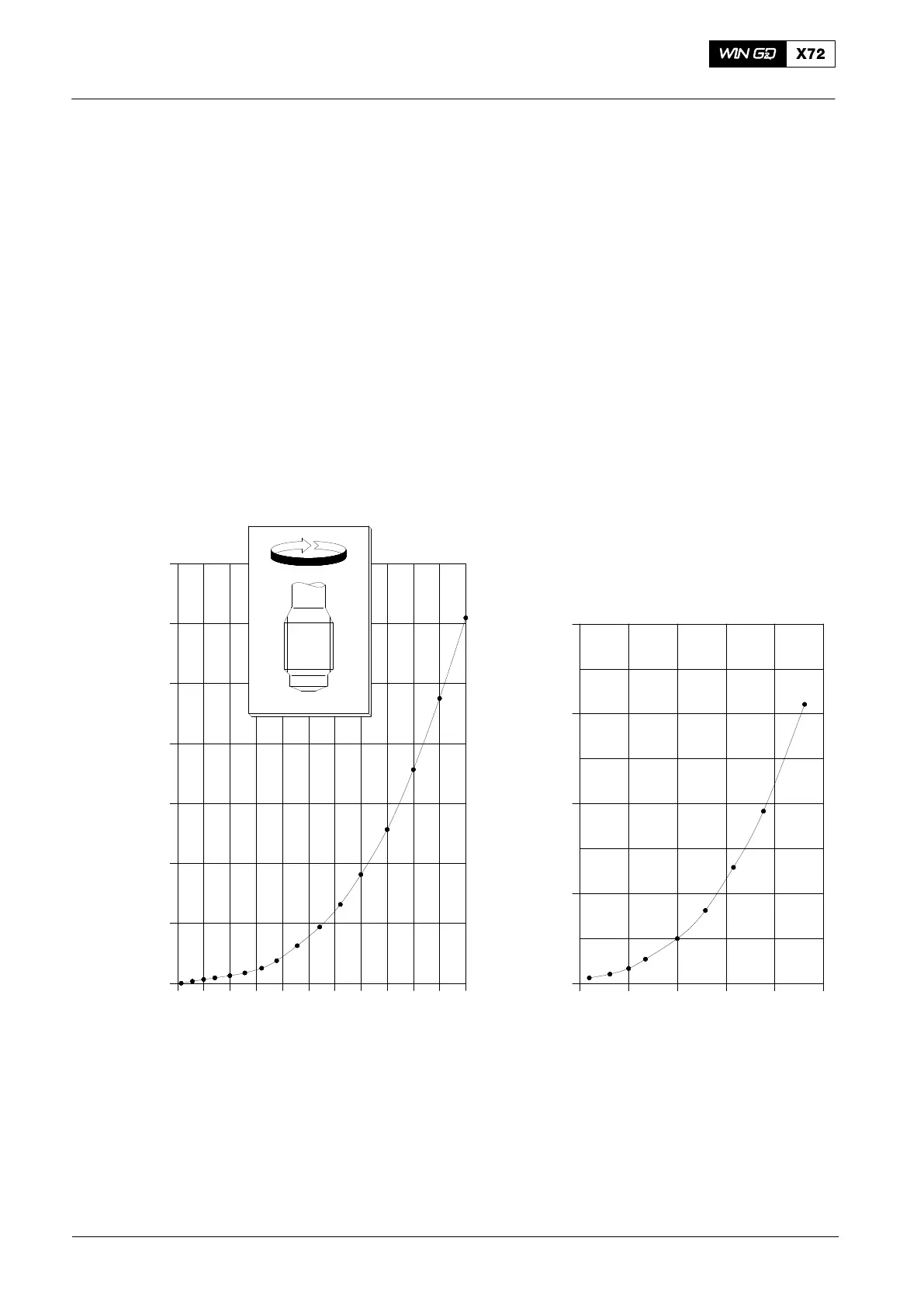

3500

3000

2500

2000

1500

1000

0

500

10 3020 40 50 60

0

70 80 100 11090 120

THREAD DIAMETER [mm]

TORQUE [Nm]

THREAD DIAMETER [mm]

001.769/97

Fig. 1

Fig. 2

2015

Torque Values − Standard Screws and Elastic Studs

Loading...

Loading...