Maintenance

3303−3/A1

Winterthur Gas & Diesel Ltd.

1/ 8

Top End Bearing − Removal, Inspection and Installation

Tools:

2 Manual ratchet, 2500kg, H1,H2 94016-011 1 Protection tool 94117B

1 Manual ratchet, 6300kg, H3 94016-017 1 Platform 94143

2 Manual ratchet, 500kg, H6,H7 94016-031 1 Support 94322

1 Chain block, 1000kg, H5 94017-006 1 Support (for iELBA) 94322A

1 Chain block, 5000kg, H4 94017-021 1 Lifting tool 94324

4 Eye bolt 94045-M8 1 Chain, 4-Sling, 1120kg 94327

2 Eye bolt 94045-M24 1 Stop plate 94335

1 Eye bolt 94045-M48 1 Lifting tool 94337

2 Shackle, 4750 94018B 2 Pre-tensioning jack 94315

2 Shackle, 8500kg 94018C 2 Pre-tensioning jack 94340

1 Chain symmetrical 94019A

1 Chain asymmetrical 94019B

1 Chain, 1000kg 94019C

1. Piston − Hold 1.....................................................

2. Preparation 2.......................................................

3. Crosshead − Lift 3..................................................

4. Bearing Shell − Removal 4..........................................

5. Bearing Shell − Installation 5........................................

6. Bearing Lubrication 7...............................................

7. Completion 8.......................................................

1. Piston − Hold

WARNING

Injury Hazard: Before you

operate the turning gear,

make sure that no

personnel are near the

flywheel, or in the engine.

1) Read the data in 0012−1 General

Guidelines for Lifting Tools.

2) Use the turning gear to turn the crank

to BDC.

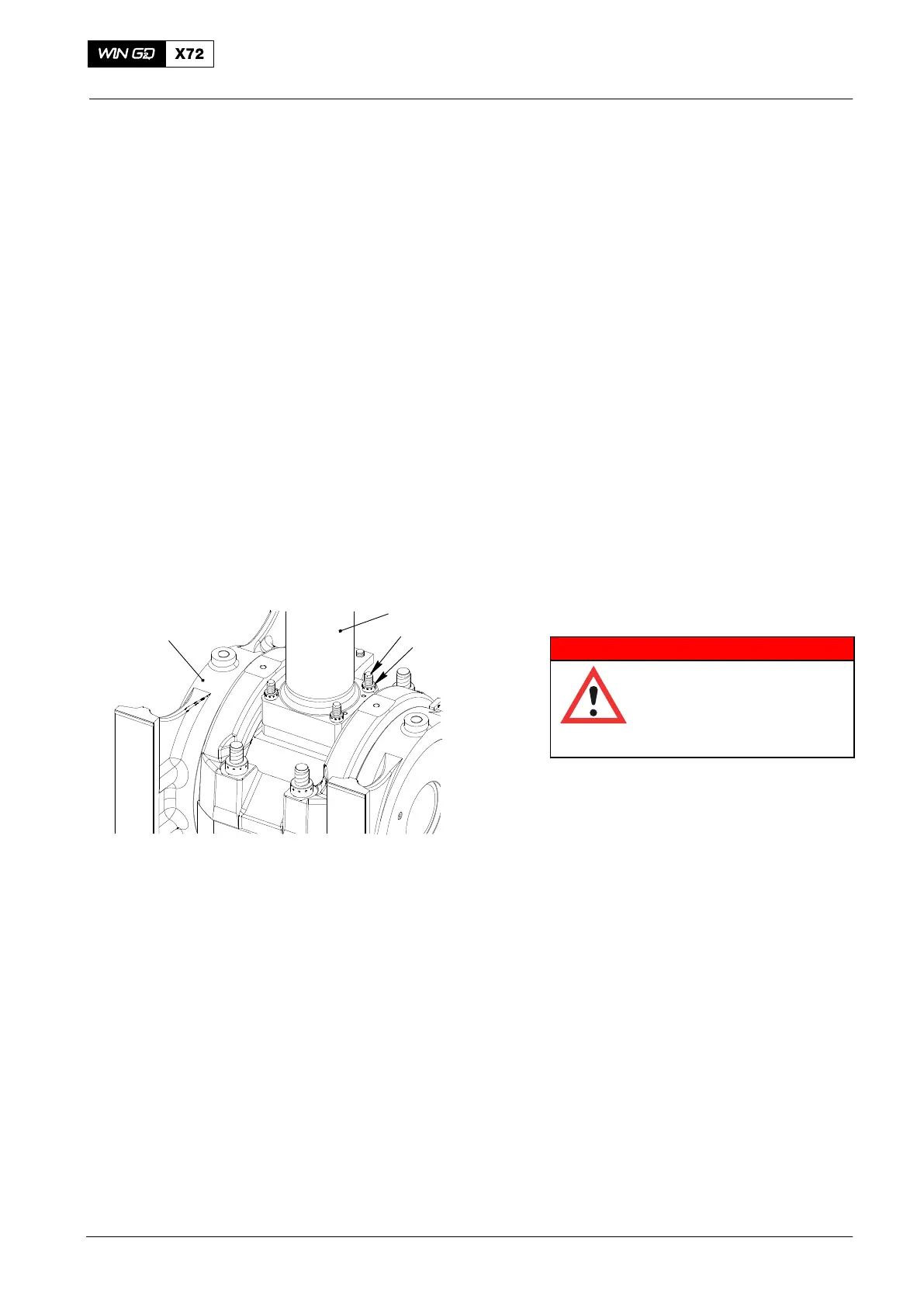

3) Apply tension to the elastic stud (5,

Fig. 1) of the piston rod foot (4), refer to

9403−4.

4) Remove the round nut (3).

5) Use the turning gear to turn crank to

TDC.

2016−02

Connecting Rod

3

4

5

2

WCH02434

Fig. 1

Loading...

Loading...