Maintenance

3303−3/A1

Winterthur Gas & Diesel Ltd.

7/ 8

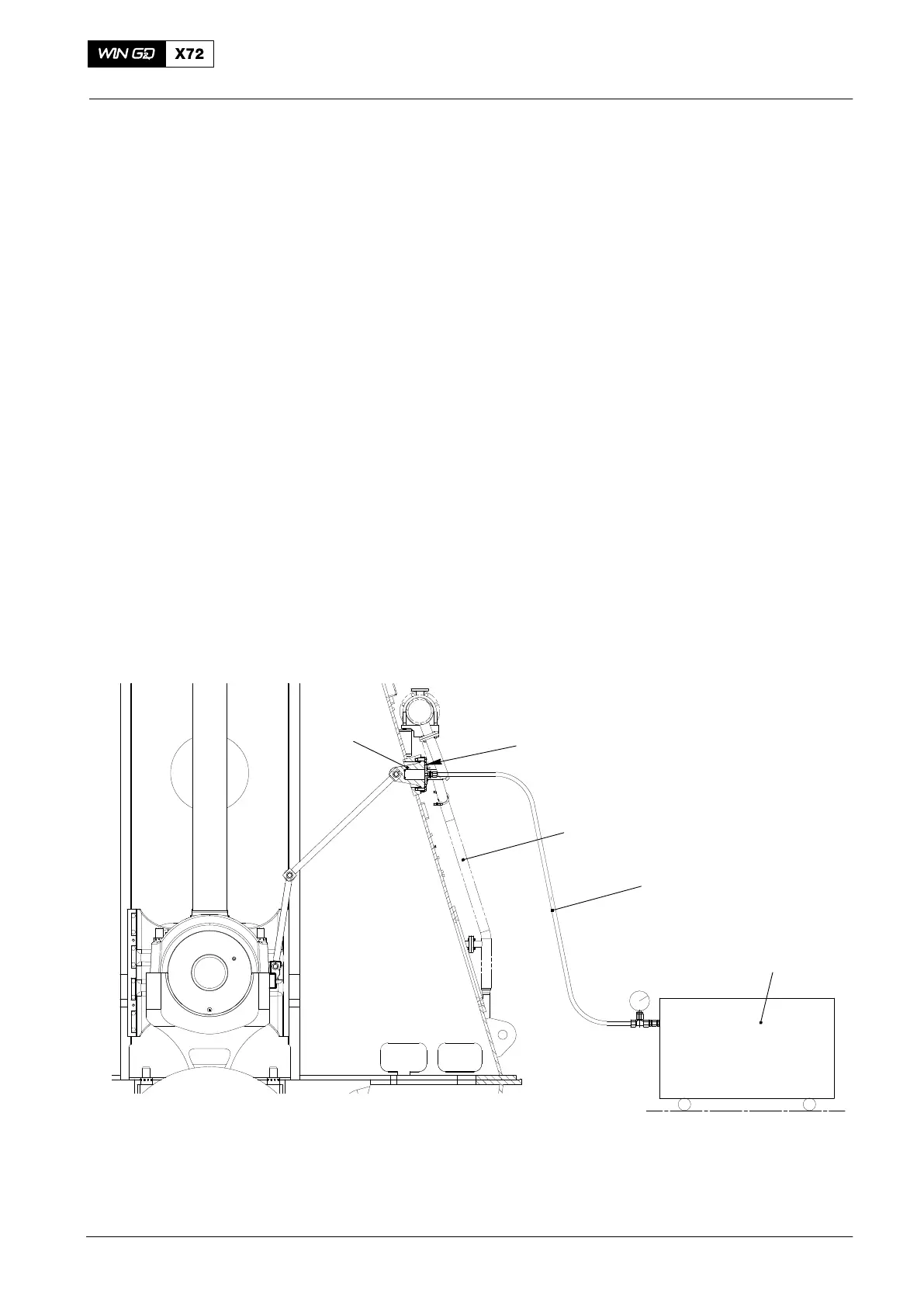

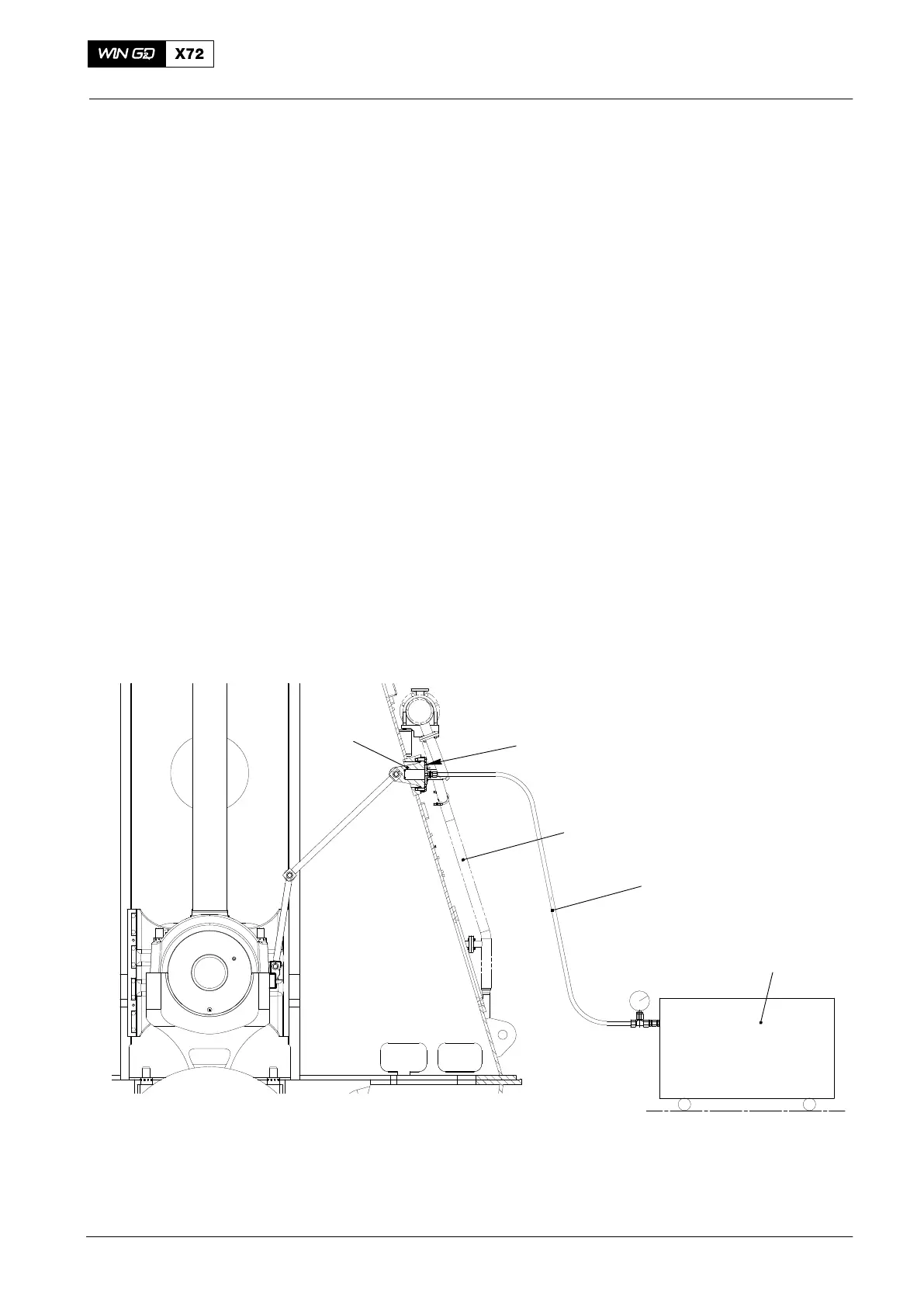

6. Bearing Lubrication

To decrease the risk of dry-running on new bearing shells, it is necessary to apply a

mixture of high-viscosity oil (steam engine cylinder oil, ISO VG 1000/1500) and

bearing oil.

1) Remove the oil inlet pipe (2, Fig. 11).

2) Attach the flange (94336) to the support (1).

3) Connect the hose (3) to the flange (94336).

4) Fill the lubricating pump (4) with steam-engine cylinder oil (see Table 1).

5) Operate the lubricating pump (4) until oil flows from the sides of the bearing.

Note: Do step 1) to step 5) weekly if the engine does not operate for some

weeks.

6) Before you operate the engine do step a) to step d):

a) Make sure that the hose (3) has no pressure.

b) Disconnect the hose (3) from the flange (94336).

c) Remove the flange (94336).

d) Install the oil inlet pipe (2) to the support (1).

Note: The steam-engine cylinder oil can stay in the oil system.

Fig. 10

94336

2

4

WCH02448

1

3

2015

Top End Bearing − Removal, Inspection Installation

Loading...

Loading...