Maintenance2722−1/A1

Winterthur Gas & Diesel Ltd.

2/ 3

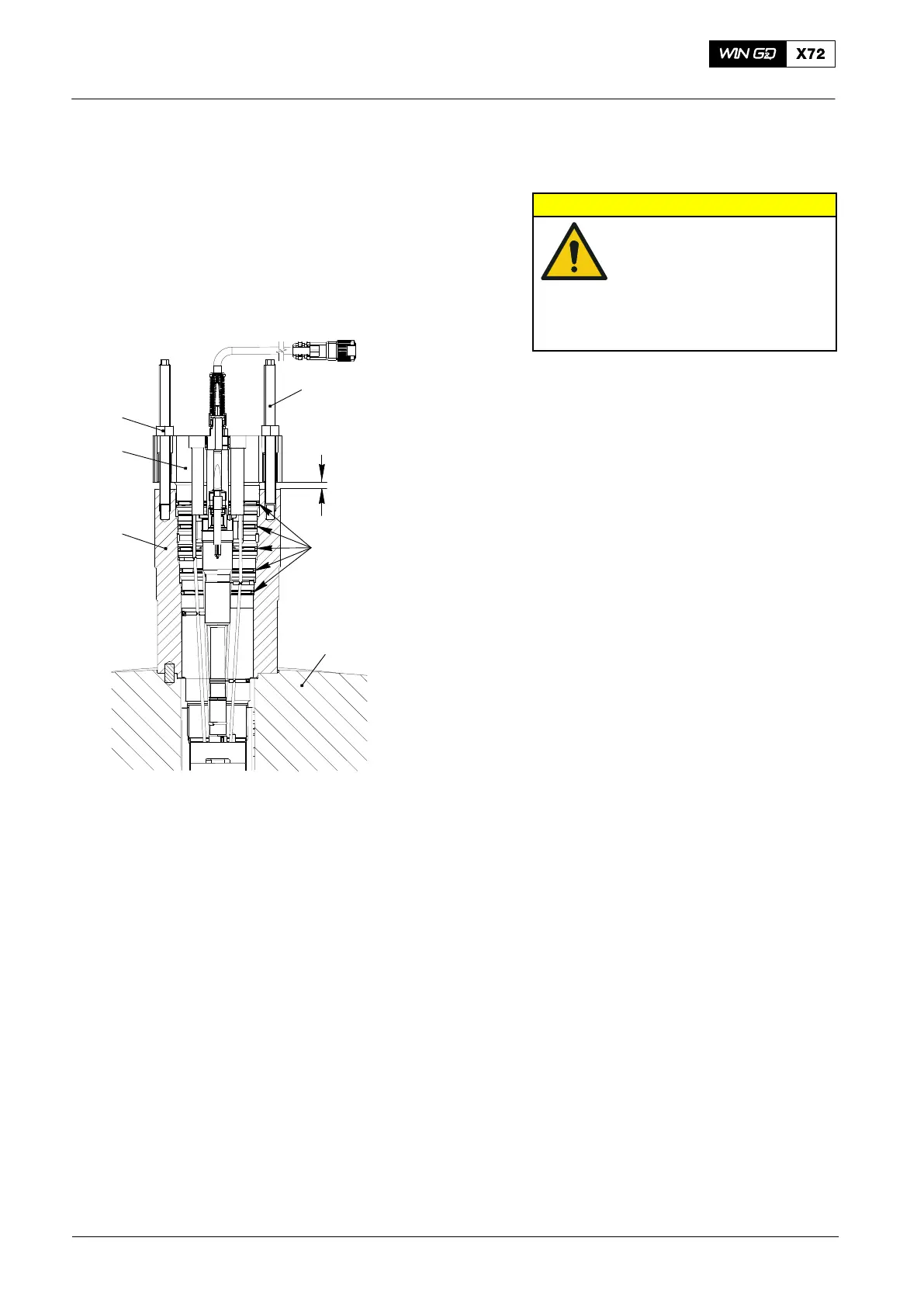

2. Installation

CAUTION

Injury Hazard: When you

do work with white spirit,

always put on gloves and

safety goggles that have a

closed side frame. White

spirit can cause damage to

your skin and eyes.

1) If applicable, remove the new injection

valve from the package.

2) Use white spirit e.g. Shellsol TD,

Shellsol T or Solvent FP68 to clean and

remove grease from the injection valve.

3) Do a check of the condition of the

sealing face in the cylinder cover (2,

Fig. 2). If necessary, re-grind the

sealing face, refer to 2708−3.

4) Put oil on the five new O-rings (1).

Note: The five O-rings (1) are included in

the spare parts set for the injection

valve.

5) Put the five O-rings (1) in their correct

positions on the injection valve (4).

6) Carefully put the injection valve (4) into

the valve bush (3).

7) Turn the two stud bolts (94270D) into

the valve bush (3) as shown in Fig. 2.

8) Turn equally the two nuts (7) to push

the injection valve into the valve bush

(3).

Note: A relatively high force is needed to

overcome the resistance of the five

O-rings. When the O-Rings are

compressed it will become easier

to push the injector in.

Note: The injection valve is fully in when

the nozzle body of the injector is

sealing with the cylinder cover (2).

This will be recognized by a

suddenly increasing force.

Theoretically the distance between

the injection valve and the valve

bush is approx. 7mm.

9) Remove the two stud bolts (94270D).

2015

94270D

1

WCH02390

Fig. 2

2

approx. 7 mm

4

3

7

Loading...

Loading...