Maintenance

2722−1/A1

Winterthur Gas & Diesel Ltd.

3/ 3

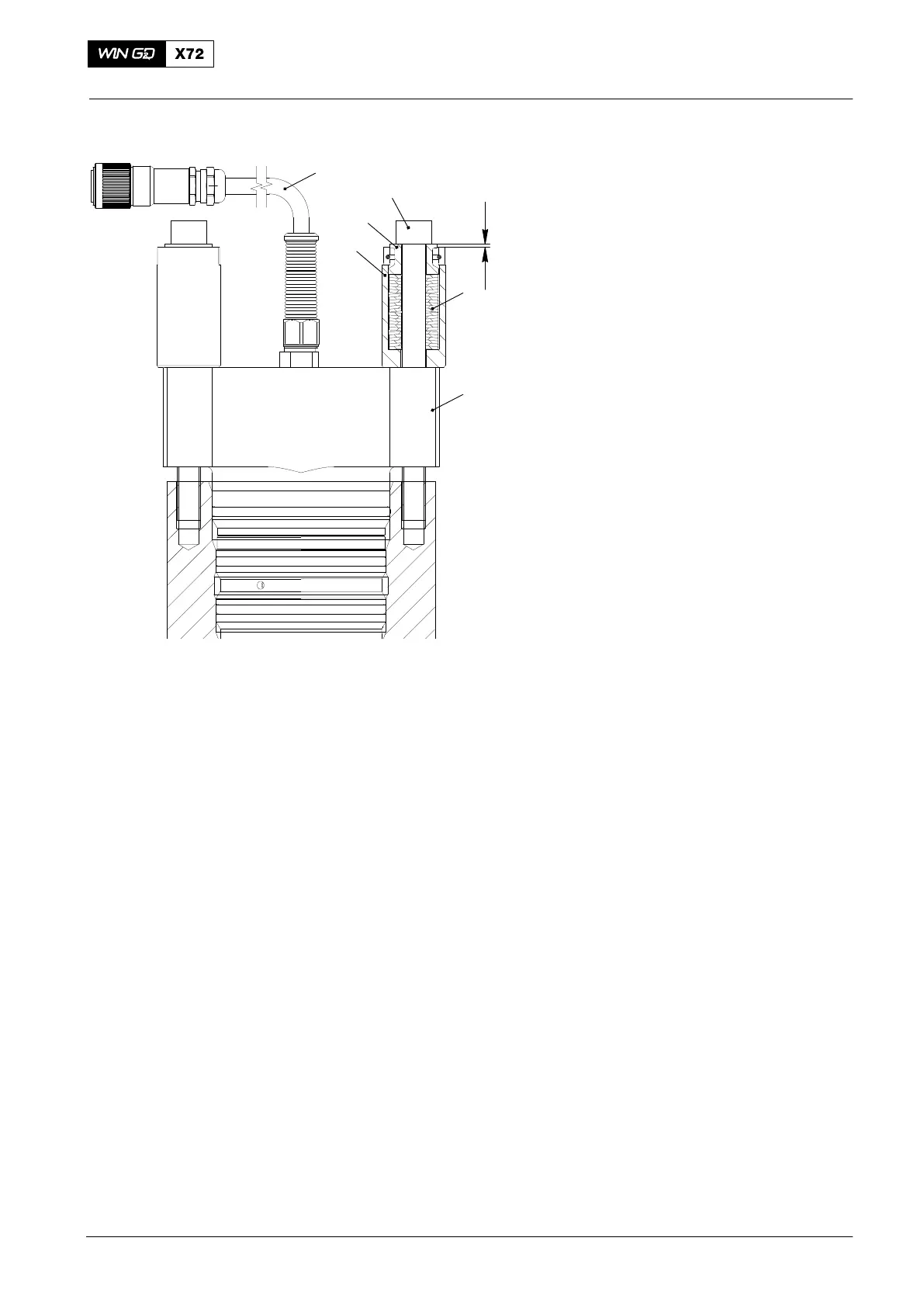

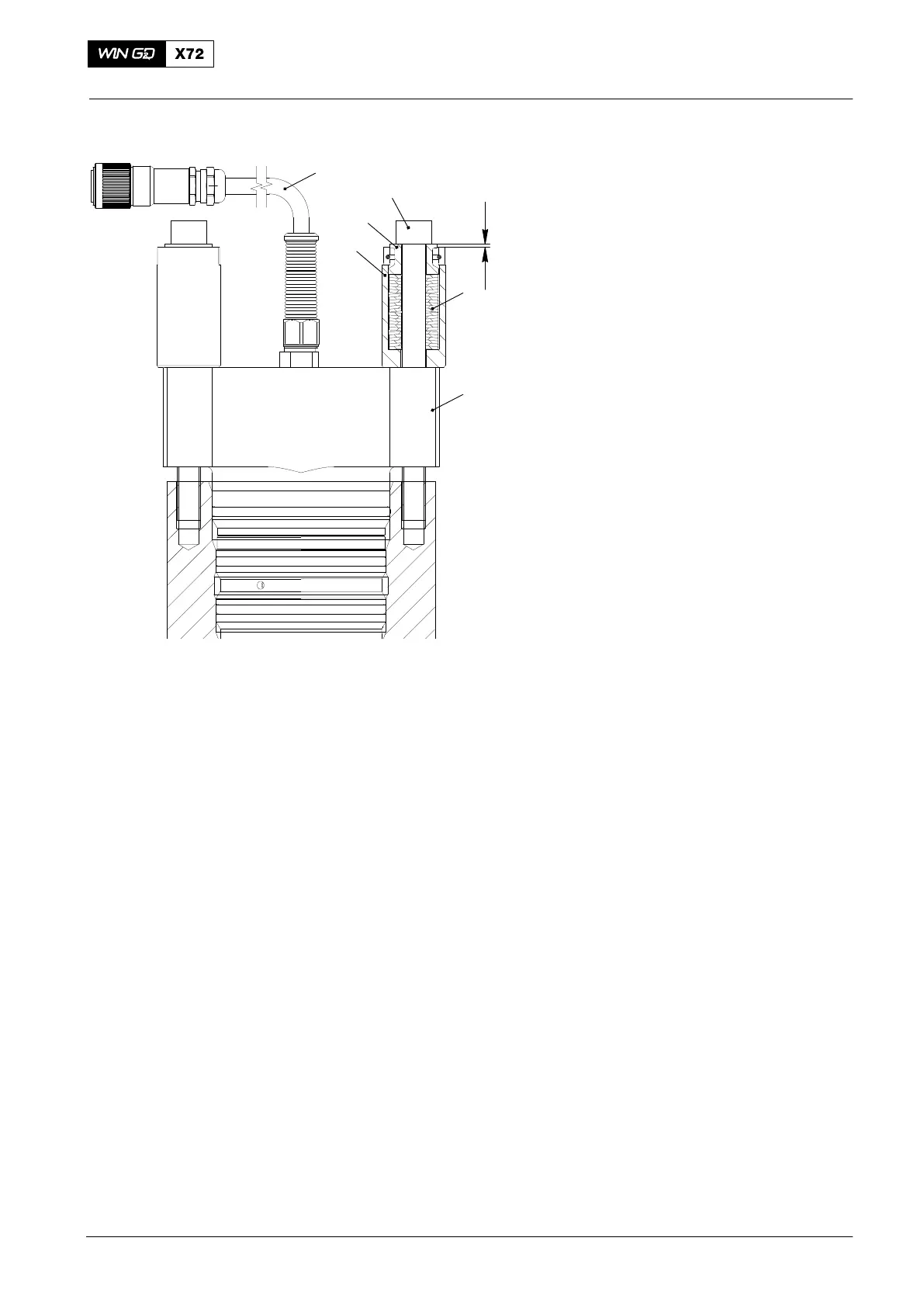

10) If the spring cage (3, Fig. 3) was

disassembled, make sure that the cup

springs (1) are installed as shown (four

sets of six cup springs).

Note: A correct assembled spring cage

has a protrusion of the

uncompressed spring guide (4) of

Y = 1.8mm

11) Put the spring cages (3) in position on

the injection valve (2).

12) Apply Never-Seez NSBT to the threads

and the seating surface of the two

screws (5, Fig. 3).

13) Tighten equally the two screws (5) until

the spring guide (4) is flush with the

spring cage (3); Y = 0mm.

Note: The tightening force is relatively

low compared to the installation

force.

14) Connect the cable (6) to terminal box

95.4.

15) Install the applicable HP fuel pipe, refer

to 8733−1.

3. Storage Area

You must make sure that the storage area is clean, dry and has no contamination in

the air.

2015

WCH02401

Fig. 3

Y

2

1

3

4

5

6

Loading...

Loading...