Maintenance

7758−1/A1

Winterthur Gas & Diesel Ltd.

9/ 13

5. Check

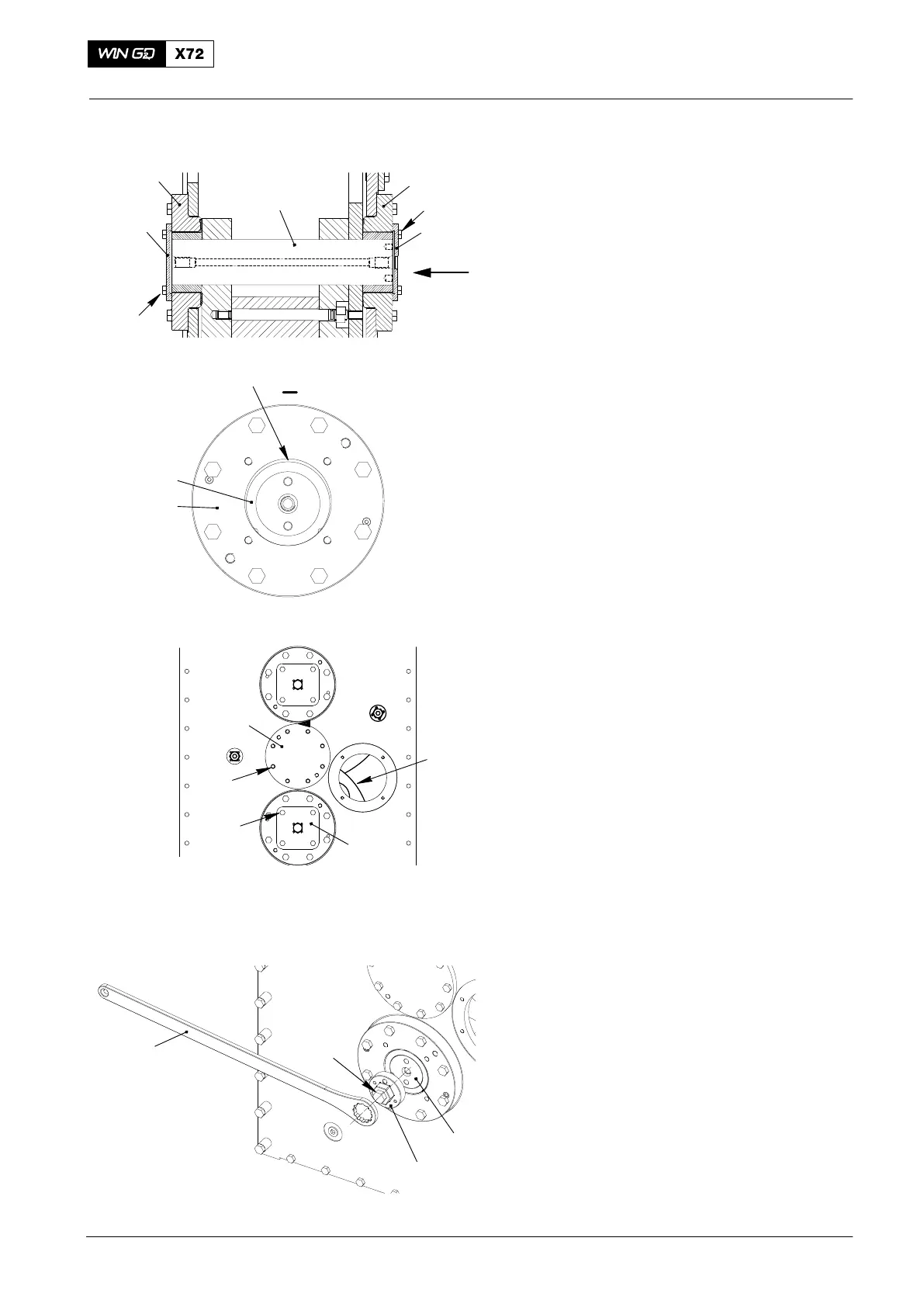

5.1 Bearing clearance

1) Remove the four screws (5) and the

locking plates on the bearing cover (4)

at the engine side.

2) Remove the bearing cover on the

engine side.

3) Remove the four screws (7) on the

bearing cover (6) at the outer side.

4) Remove the bearing cover (6).

5) Use a feeler gauge to measure the

clearance between pin (1) and bearing

(2) and (3) at the upper position (FG).

6) Compare clearance with the data given

in 0330−1.

7) Replace bearing if clearance is more

than the allowed maximum clearance.

8) For the first time, it’s recommended to

call WinGD for expert advice.

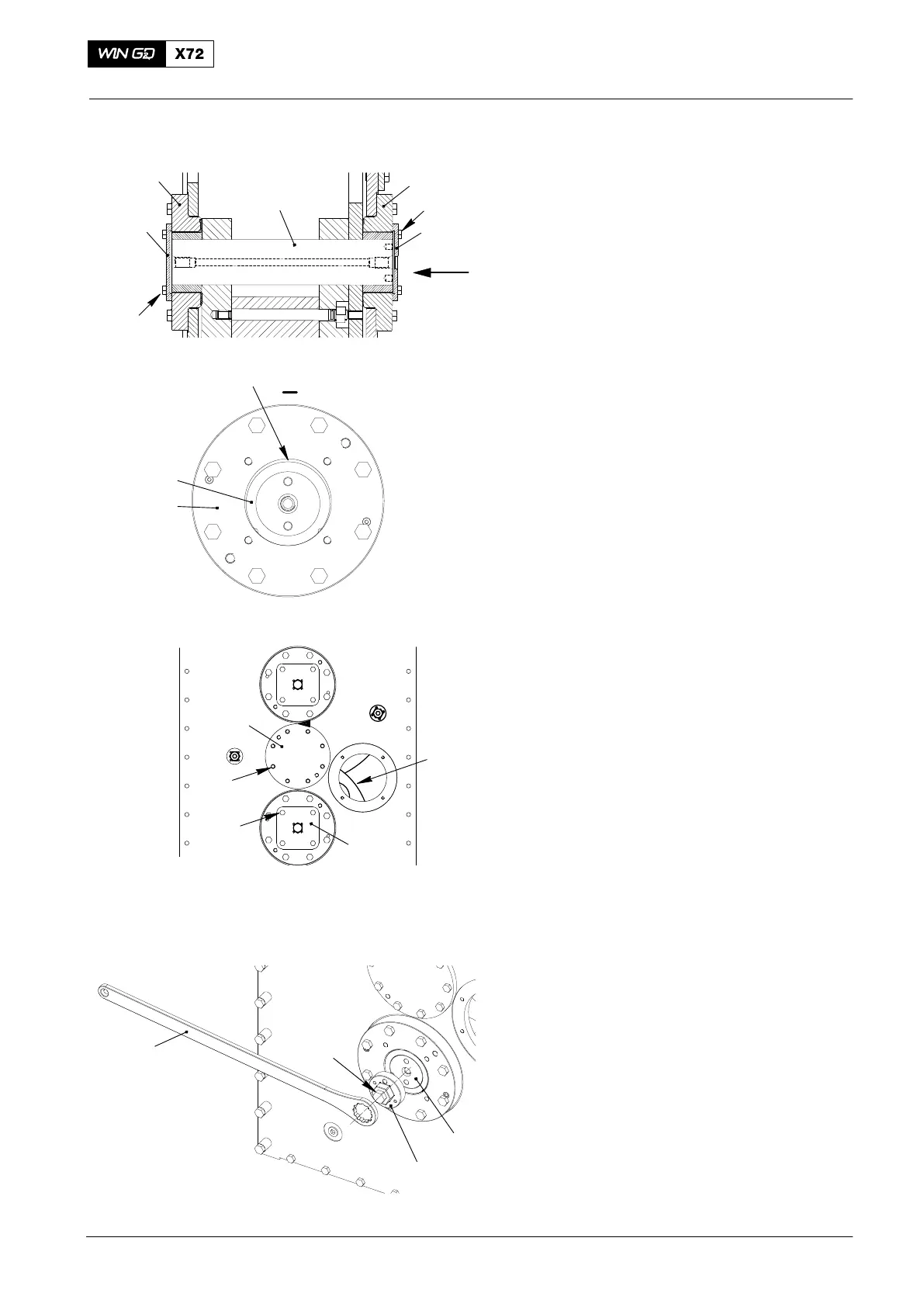

5.2 Measure Backlash

1) Remove the eight screws (4, Fig. 11)

and the cover (5).

2) Make sure the clamping screws (4, Fig.

2) are removed.

3) The service hole (8) to measure the

backlash between motor pinion and

lower gear wheel is reachable from

inside the engine.

4) Remove the four screws (7) on the

lower bearing cover (6) at the outer

side.

5) Install turning device 94703 for turning

the gear wheels, as follows:

D Install the socket insert (5, Fig 12) with

the screw (6) on the pin (4) of the lower

bearing. Tighten the screw (6) with

100 Nm.

2016

Integrated Electric Balancer

FG

5

I

I

6

ENGINE SIDE

OUTER SIDE

4

1

3

2

7

1

2

Fig. 10

6

7

Fig. 11

WCH03465

4

5

8

94703

5

Fig. 12

6

4

Loading...

Loading...