Maintenance

7758−1/A1

Winterthur Gas & Diesel Ltd.

3/ 13

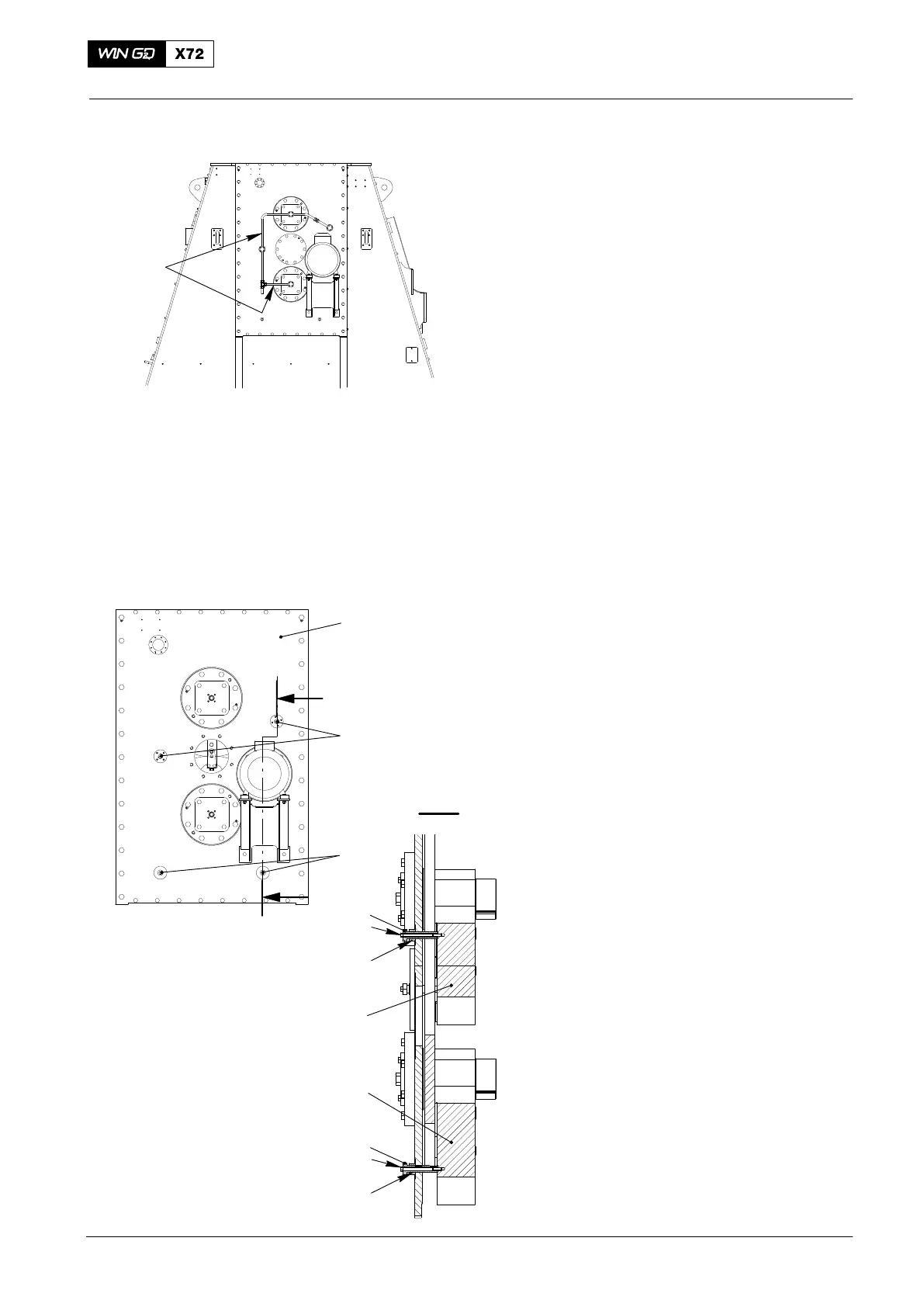

2. Preparation

1) Stop the engine, refer to Operation

Manual, 0310−1.

2) Make sure that the electric motor (5,

Fig. 1) has stopped.

3) Stop the lubricating oil supply and close

the oil inlet.

4) At driving end, put an oil tray under

applicable oil pipe (1, Fig.2).

5) Remove the applicable oil pipe (1) to

get access to the balancer shafts.

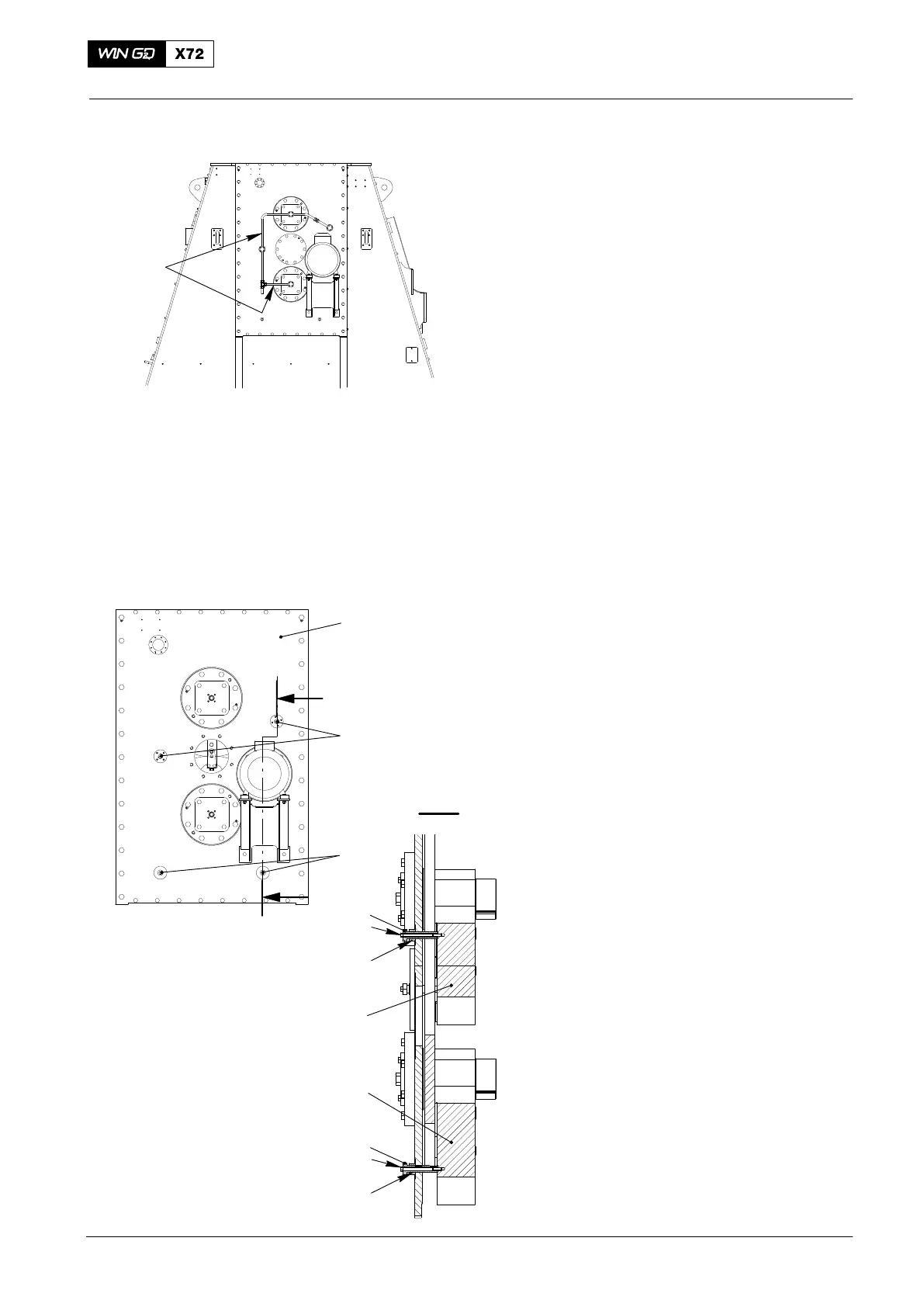

3. Counterweights − Lock

3.1 Top Counterweight

1) Apply lubricating oil to the thread and

bottom of the head of the clamping

screw (4, Fig. 3) and the nut (6).

2) Remove the two screws (2) from the

main cover (1).

3) Put the two clamping screws (4) and

the nuts (6) in position on the upper

counterweight (10).

4) Torque the clamping screws (4) to

60 Nm.

5) Torque the nut (6) to 60 Nm.

6) Put the the M12 bolt (5) in position

through the clamping screw (4).

7) Torque the M12 bolt (5) to 60 Nm.

3.2 Bottom Counterweight

1) Apply lubricating oil to the thread and

bottom of the clamping screw (7) and

the nut (9).

2) Remove the two screws (3) from the

cover (1).

3) Put the two clamping screws (7) and

the nuts (9) in position on the lower

counterweight (11).

4) Torque the clamping screws (7) to

60 Nm.

5) Torque the nut (9) to 60 Nm.

6) Put the M12 bolt (8) in position through

the clamping screw (7).

7) Torque the M12 bolt (8) to 60 Nm.

2016

Integrated Electric Balancer

WCH03566

DRIVING END

1

1

2

3

I

I

WCH03465

4

5

6

I - I

7

8

9

10

11

Fig. 2

Loading...

Loading...