Maintenance

3303−3/A1

Winterthur Gas & Diesel Ltd.

3/ 8

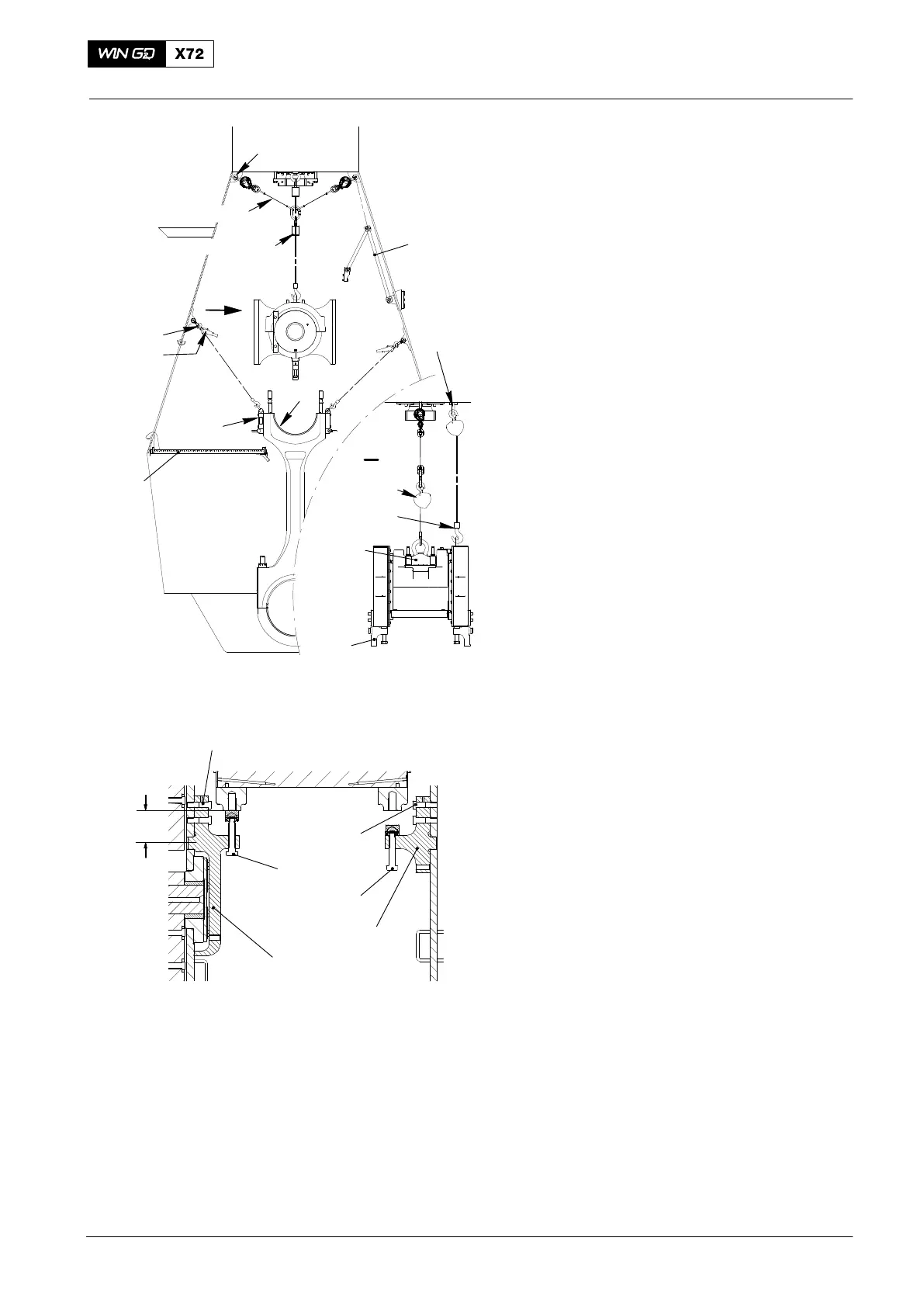

3. Crosshead − Lift

1) Attach the shackles (94018B, Fig. 4) to

each side of the column.

2) Attach a manual ratchet (H1, H2) to the

shackles (94018B) and the the two

lifting tools (94337).

3) Apply a light tension to the manual

ratchets (H1, H2).

Note: If the cylinder cover and piston are

removed you can use the engine

room crane and chain block H4 to

lift the crosshead.

4) Attach the chain (94019B) to the two

shackles (94018C).

5) Attach the manual ratchet (94016-017,

H3) to the chain (94019B).

6) Attach the manual ratchet (94017-21,

(H4) to the eye bolt (94045-M48) at the

top of the column and the eye bolt on

the bearing cover, see View I.

7) Operate the chain block (H3) to lift the

crosshead approximately 300 mm

above the plug bore center (see Fig. 5)

in the column.

8) Keep the tension on the chain block

(H4, Fig. 4).

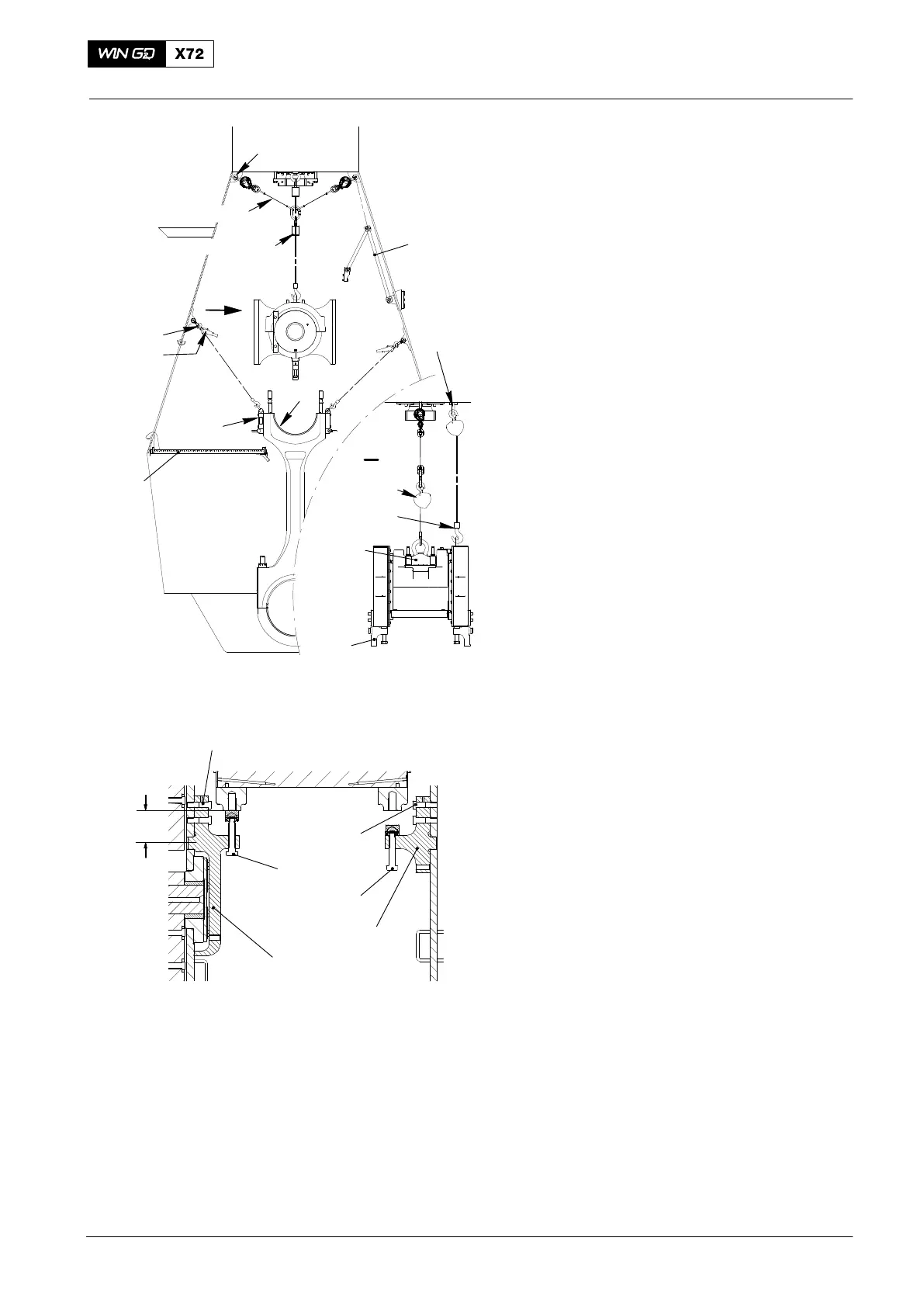

Note: Fig. 5 shows an engine with

electric Balancer (iELBA). Use two

supports 94322 for engines

without balancer.

9) Attach the two supports (2x 94322 or

for iELBA: 1x 94322A and 1x 94322)

with the four bolts (1, 4, Fig. 5).

10) Torque the four bolts (1,4) to 300 Nm.

11) Lower the crosshead for 140 mm

(160 mm above plug bore center).

12) Tighten the special screws (2, 3).

13) Inspect the bearing shell 13.

14) If it is necessary to replace the bearing

shell, refer to paragraph 4, step 1) to

step 10).

15) Remove the platform (94143, Fig. 4).

2016−02

Top End Bearing − Removal, Inspection Installation

94016-011

94018B

94337

94018C

94019B

94016-017

I

I

94016-17

94017-21

94322

10

94324

94045-M48

(H2)

H1

(H3)

(H3)

(H4)

94143

WCH02433

13

Fig. 4

Fig. 5

WCH03209

94322

2

94322A

3

160 mm

1

4

Loading...

Loading...