Maintenance3403−1/A1

Winterthur Gas & Diesel Ltd.

2/ 6

14) Remove the four inner bolts (2, Fig. 3)

from the support 1).

15) Use turning gear to turn crank slowly to

TDC while pushing out piston rod gland

(7).

16) Make sure that the two distance

holders (94230) stay in line with the

gland box.

17) Clean the threads of the piston

suspension device (94341) with water.

18) Put oil on the threads and the surfaces

of the four screws (1).

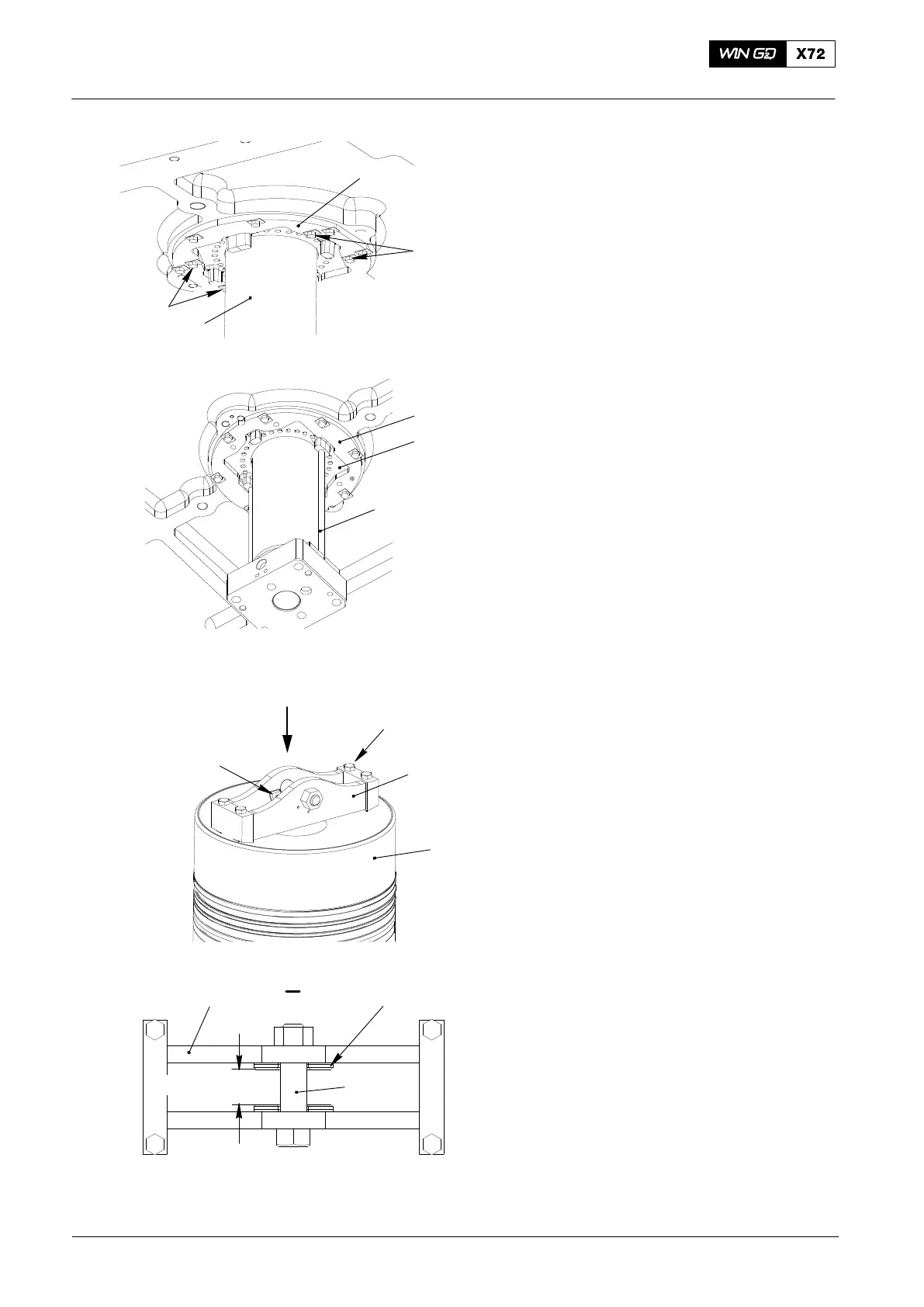

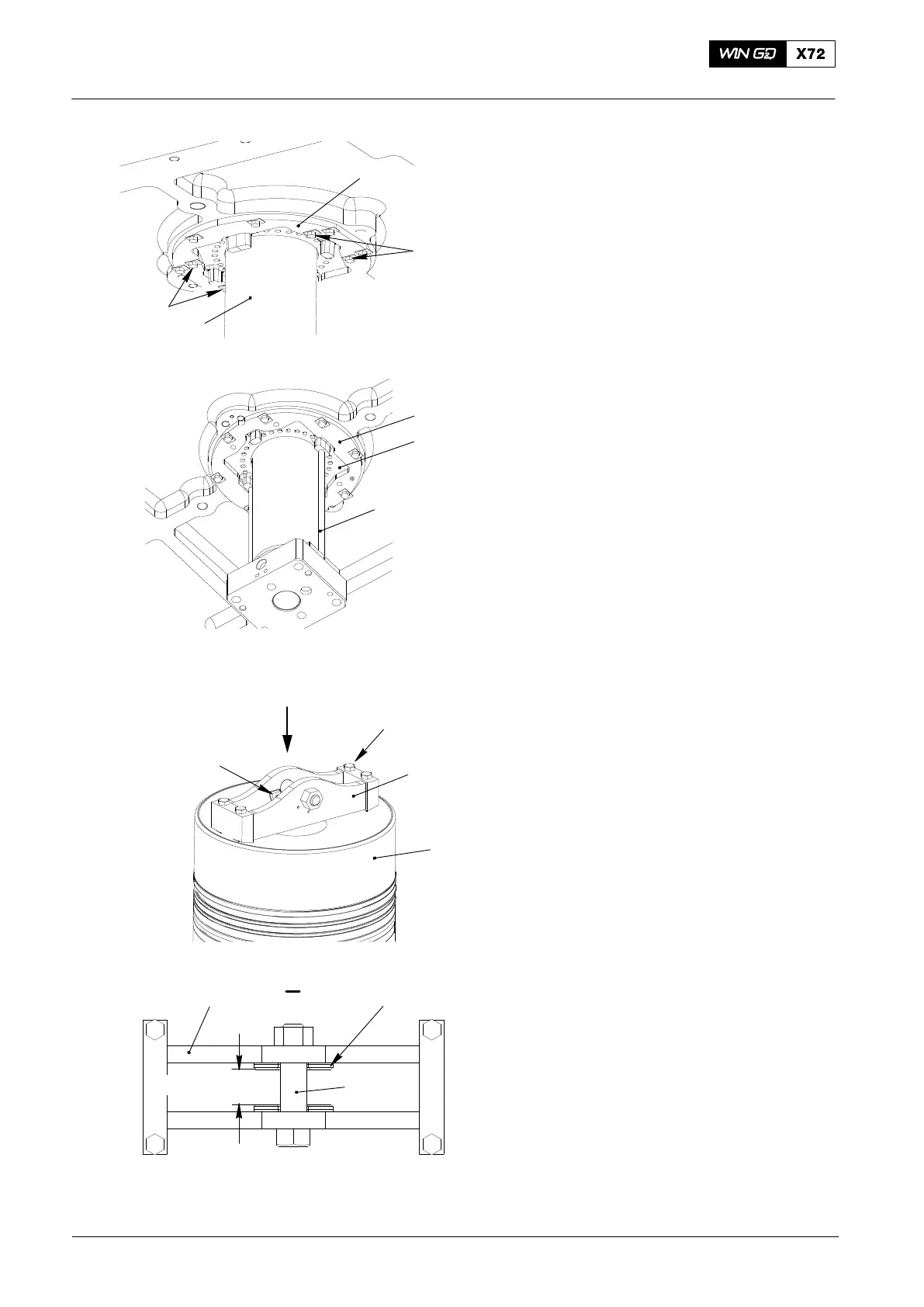

19) Attach the piston suspension device

(94341) to the piston (2) with the four

screws (1).

20) Torque the screws (1) to 60 Nm.

Note: Before you use the suspension

device (94341) for the first time,

the axial clearance between the

crane hook and suspension device

must be adjusted.

Note: The axial clearance between the

plates of the suspension device is

related to the size of the crane

hook. You use the plates (94341A)

to adjust this clearance.

21) Put the applicable quantity of plates

(94341A) in position to get the axial

clearance to between 2.0 mm and

5.0 mm.

22) Connect the crane hook to the piston

suspension device (94341).

23) Measure the clearance between the

crane hook and the shaft (3) of the

suspension device (94341). Make sure

that the clearance is between 2 mm

and 5 mm.

2015

Piston: Removal and Installation

Fig. 3

WCH02456

94341

94341A

Fig. 4

WCH02600

94230

1

2

I

94341

94341A

I

32 mm to 5 mm

WCH02435

1

2

2

3

1

2

Fig. 5

Loading...

Loading...