Maintenance1132−2/A1

Winterthur Gas & Diesel Ltd.

8/ 14

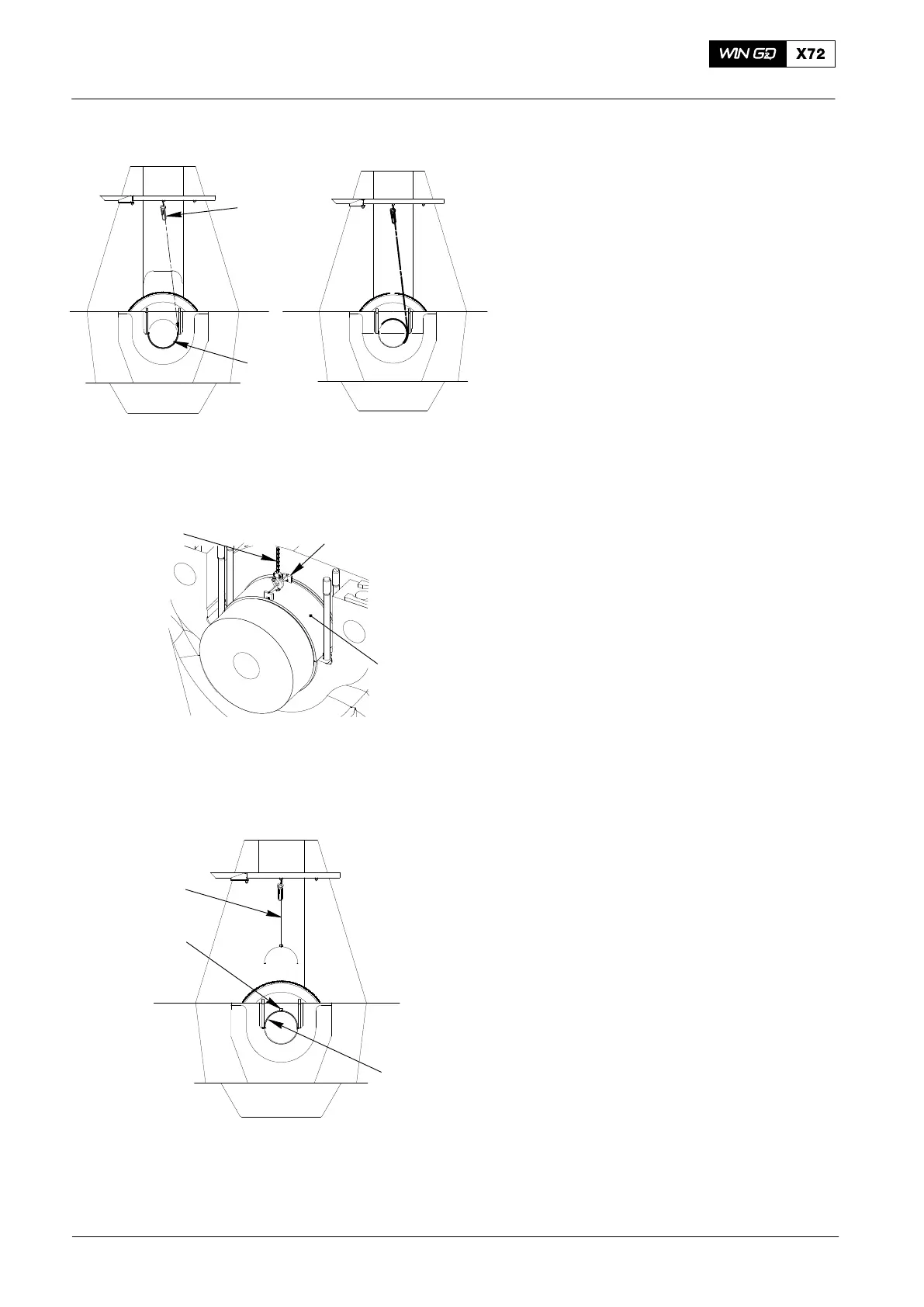

8) Operate the spur-geared chain block

(94017-006, Fig. 17) to turn the bearing

shell (1) as shown in Fig. 18 and

Fig. 19.

Note: If the bearing shell (1) does not

move, the lifting plate (94119,

Fig. 16) must be attached to the

other side of the dismantling tool

(94118A). The bearing shell must

be moved back to its initial

condition and you must do the

removal procedure done again.

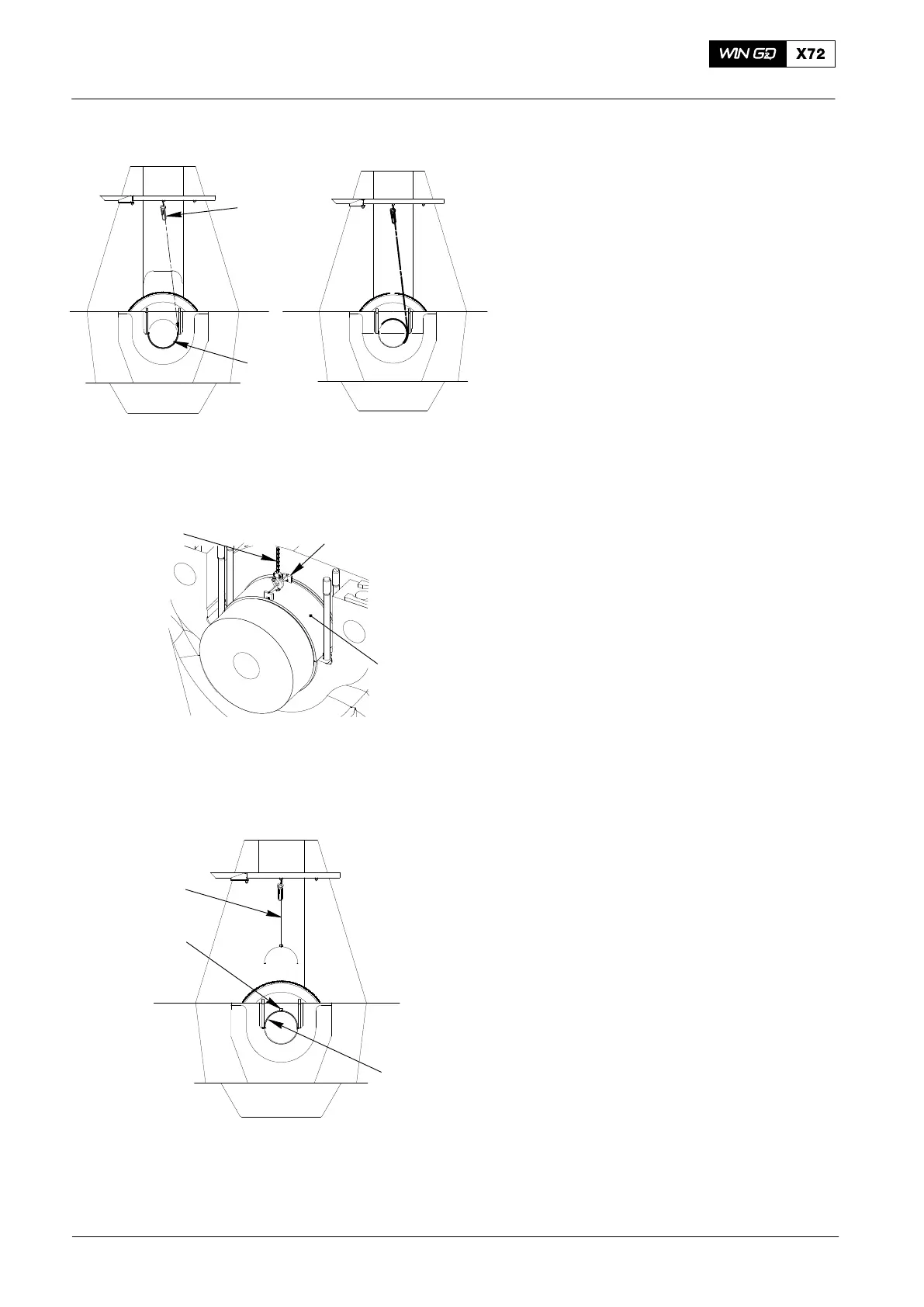

9) Remove the bearing shell (1, Fig. 19)

out as shown in Fig. 20.

10) Remove the dismantling device

(94118A).

11) Install the lifting tool (94116B) to the

bearing shell (1).

12) Remove the spur-geared chain block

(94017−005) from the lifting plate

(94119).

13) Attach the spur-geared chain block

(94017−005) to the lifting tool (94116B).

14) Remove the lifting plate (94119).

15) Operate the spur-geared chain block

(94017−006) to lift the bearing shell (1).

16) Move the bearing shell (1) to an area

where you can operate the engine

room crane.

17) Attach the engine room crane to the

bearing shell.

18) Remove the spur-geared chain block

(94017−006).

19) Operate the engine room crane to

move the bearing shell to a safe area.

2015

Main Bearing − Removal and Installation

1

94017−006

1

94116B

94116B

94017−006

94017−006

Fig. 17

Fig. 18

Fig. 19

Fig. 20

1

Loading...

Loading...