5 SUPPLEMENT

5-54

Coordinates of the origin of feature coordinate

system. To be specified with its absolute values in

the currently active workpiece coordinate system.

±99999.9999 (mm)

±9999.99999 (in)

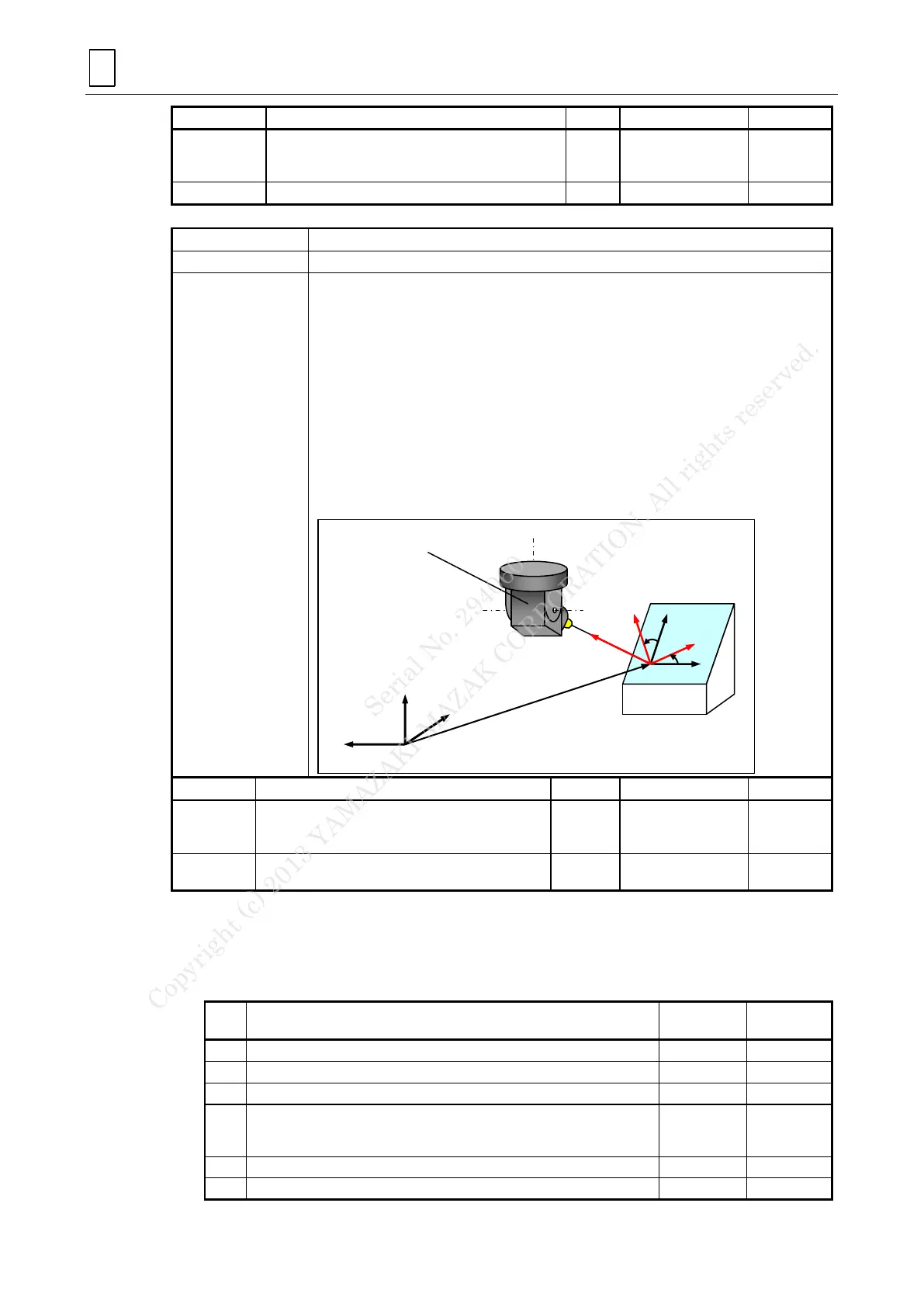

(Setting with tool-axis direction)

Point (x, y, z) in the current workpiece coordinate system is set as a new origin.

The feature coordinate system’s X-, Y-, and Z-axis are determined as follows.

The feature coordinate system’s Z-axis is set to be parallel with the current direction of

the tool axis.

The X-axis is inclined, with reference to the workpiece coordinate system, so as to

correspond with the angular positions of the tool. (The X-axis is, therefore, orientated in

parallel with the original one if the machine coordinates of the tool on its rotational axes

are 0°.)

The Y-axis is inclined, with reference to the workpiece coordinate system, so as to

correspond with the angular positions of the tool. (The Y-axis is, therefore, orientated in

parallel with the original one if the machine coordinates of the tool on its rotational axes

are 0°.)

Finally, the feature coordinate system is rotated around the Z-axis by an angle of °.

Coordinates of the origin of feature coordinate

system. To be specified with its absolute values in

the currently active workpiece coordinate system.

±99999.9999 (mm)

±9999.99999(in)

Angle of rotation around the Z-axis of the feature

coordinate system.

2. Notes

There are two programming types provided for inclined-plane machining (the selection

between which is to be done with parameter F34 bit 4): type A for combined use with

the other five-axis machining functions, and type B allowing various types of

interruption. This document mainly expounds upon Type A.

Combined use with the tool tip point control (G43.4/G43.5)

Combined use with the workpiece setup error correction (G54.4)

Combined use with the tool radius compensation for five-axis machining

Resumption of automatic operation after interruption without having

restored the positional conditions (in the use of manual interruption or

TPS function)

Changing the position on a rotational axis during interruption

Interruption using the manual pulse handle

Conversion by means of

tool axis direction

Workpiece coordinate system

1) Translation of the system

2) Orientation of the system

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...