4 MACHINING PROGRAM

4-36

B. Program composition

C. Parameter setting

The main parameter of processing is described.

The table shows the standard parameter and setting set in this manual.

Parameter setting

High-speed smoothing control valid

(No deceleration at very slightly stepped sections)

Tool tip point control scheme Joint interpolation

Rotational axis shape correction Valid

Moving axes by using G49 (tool length offset cancel) in G43 (tool

length offset) mode Invalid

Note : See 4-4-5: 5-axis machining program for the tool tip point control (G43.4).

G61.1

M108

G90G53Bb

G90G00Cc.

G90G43G00XxYyZzBbCcHhP1

B107

G05P2

G01XxYyFf

(Machining pattern)

G00XxZz

G05P0

G64

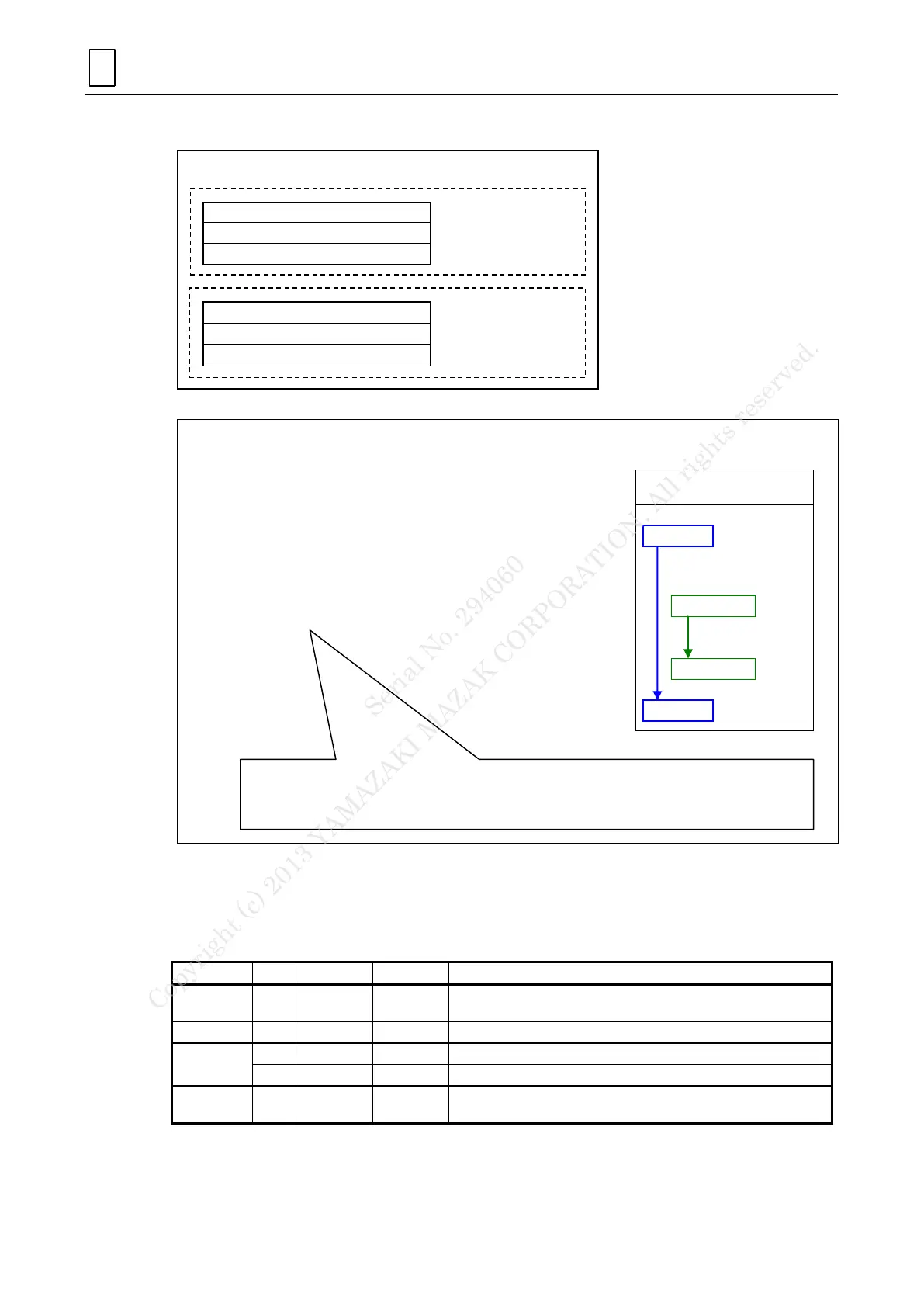

Machining motion of program composition -4-axis machining-

Note: Feed rate based on work may differ from F command if there are rotation commands in the

blocks.

Use G43.4 tool tip point control function if possible. (Reference: 4-4-5 5-axis machining

program)

--- Geometry compensation

--- B-axes unclamping

--- B-axis positioning

--- C-axis positioning

--- Tool length offset (P1)

--- B-axes clamping

--- High-speed machining mode ON

--- Head block for machining contour

--- Machining pattern

--- Escape

--- High-speed machining mode OFF

--- Geometry compensation OFF

High-speed

machining mode

The figure below indicates

setting of each mode

Instruction in

machining motion

Instruction in

preparation motion

for machining

High-speed machining mode

Program composition element

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...