MACHINING PROGRAM 4

4-41

Note 2: Coordinate system for controlling the tool tip point is defined as follows.

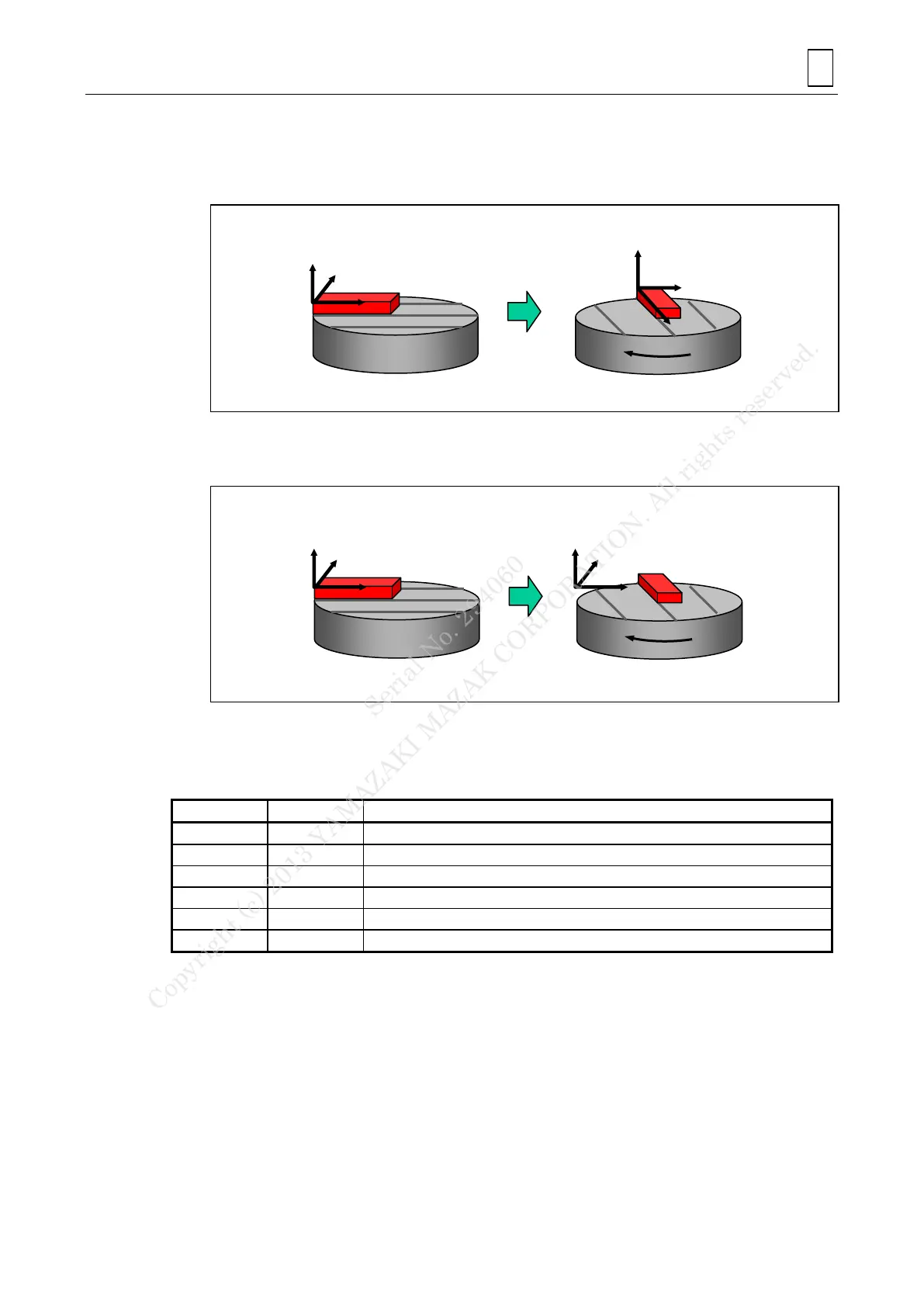

The TABLE coordinate system (F85 bit 2: 0)

The table coordinate system will rotate as the table rotates.

But the tool axis rotation (e.g. the B axis for INTE) does not rotate the coordinate.

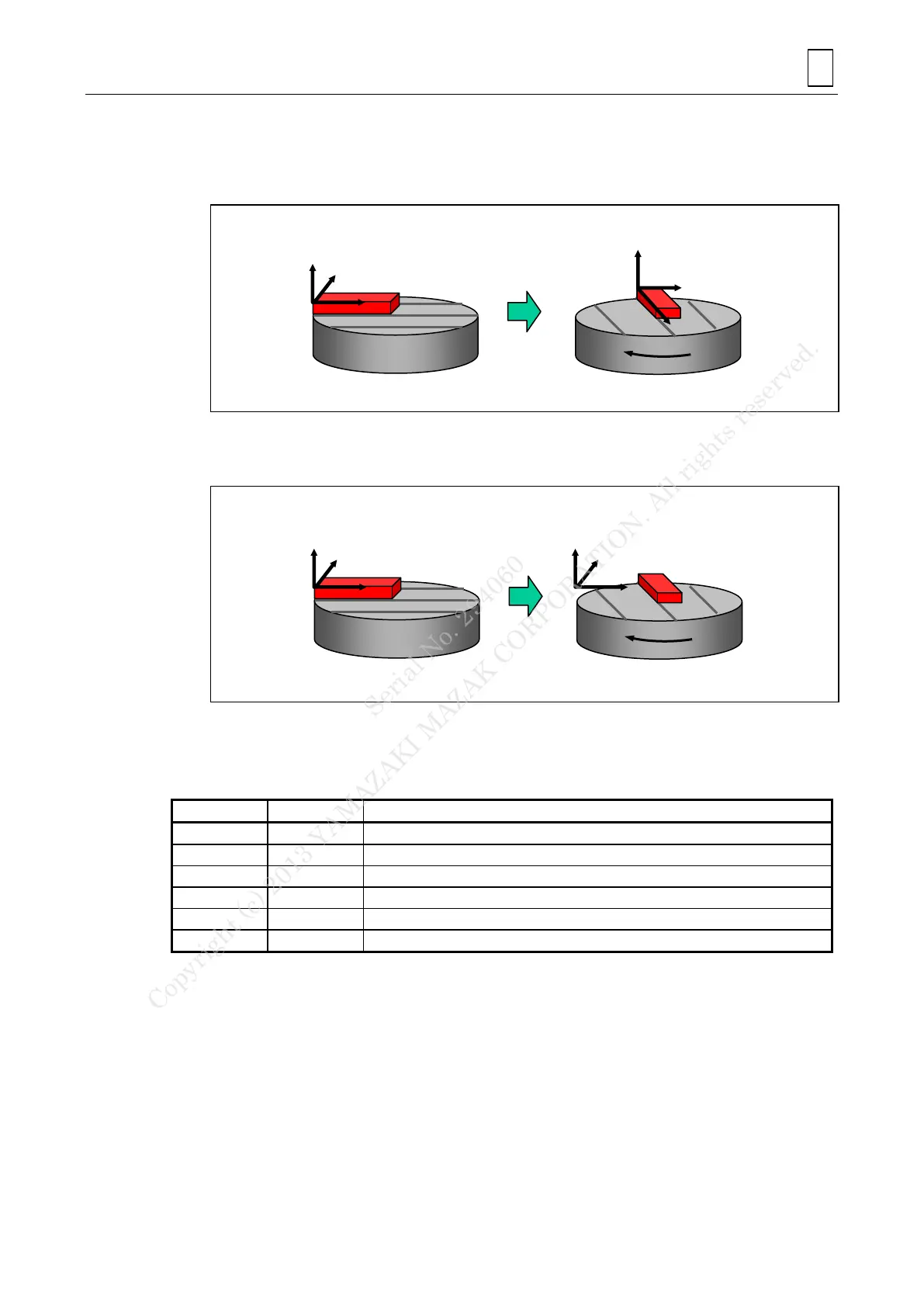

The WORK PIECE coordinate system (F85 bit 2: 1)

The current workpiece coordinate is the programming coordinate system which is fixed in

the orthogonal coordinate and does not rotate with the table.

D. G-codes/M-codes

See the document [99 Supplement] for details.

G-codes

High-speed machining mode OFF

High-speed machining mode ON

Tool tip point control (Type 1) ON

High-accuracy mode (Geometry compensation)

Note 1: The geometry compensation reduces geometry errors caused by the delay in the

smoothing circuits and servo systems.

Note 2: The high-speed machining mode features high-speed execution of free form programs

such as die and mold machining approximated by fine increments data.

Combined with the geometrical correction function, it produces high quality surface

finish.

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...