4 MACHINING PROGRAM

4-44

B. Program composition

Machining motion of program composition

-Tool radius compensation for 5-axis machining-

G61.1

M108

G90G53Bb

G90G00Cc

G43.4G00XxYyZzBbCcHh

G41.5Dd

G01XxYyZzFf

(Machining pattern)

G0XxYyZz

G40

G49

G64

--- Geometry compensation ON

--- B-axis unclamping

--- B-axis positioning

--- C-axis positioning

--- Tool tip point control ON

--- Tool radius compensation for

5-axis machining

--- Head block for machining

contour F-code

--- Machining pattern

--- Escape

--- Tool radius compensation for

5-axis machining OFF

--- Tool tip point control OFF

--- Geometry compensation OFF

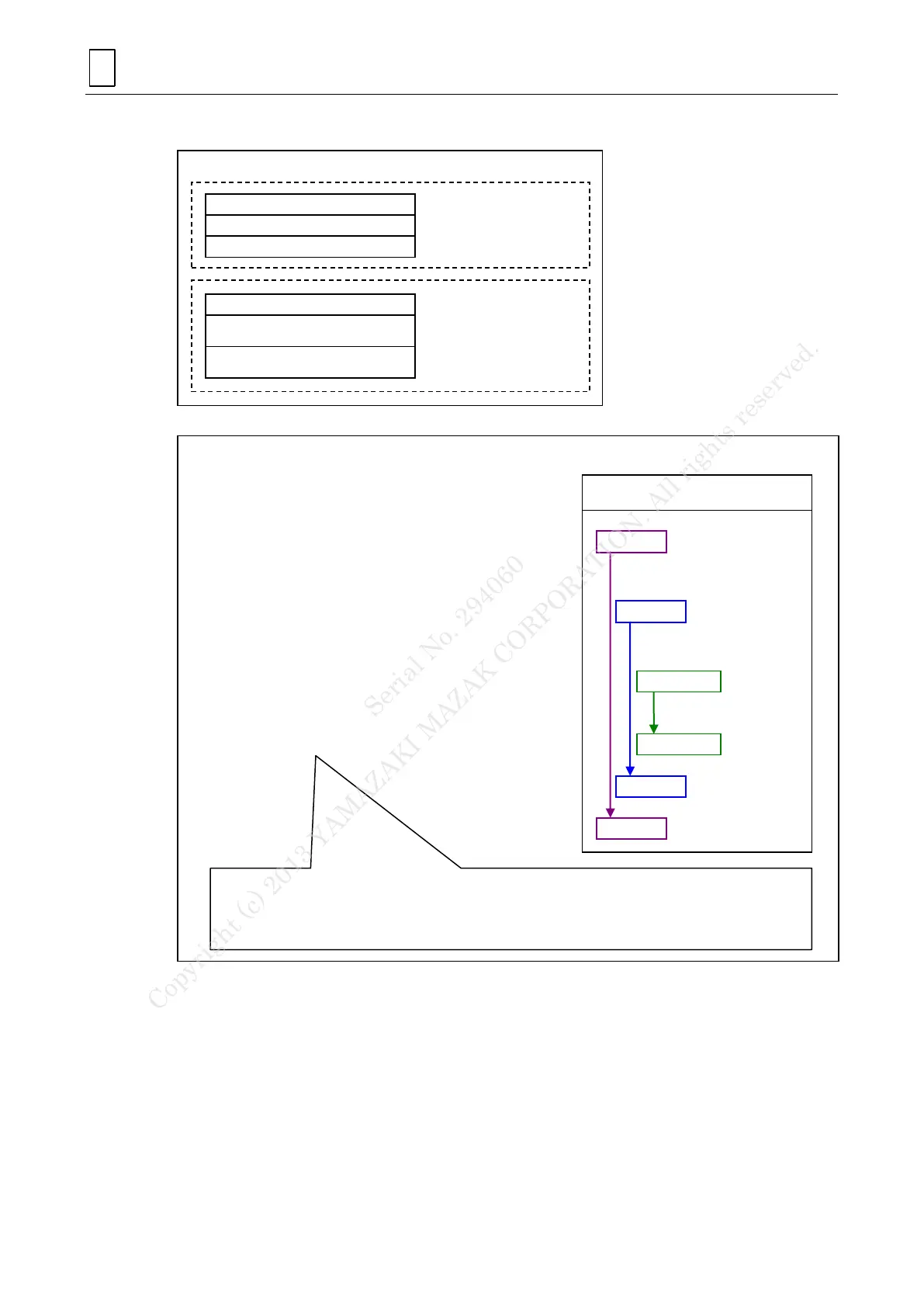

Tool radius compensation

for 5-axis machining

The figure below indicates setting of

each mode

Note 1: G43.4 should be commanded after the positioning of B and C axis, otherwise a large C axis motion

will cause unexpected motion.

Note 2: Giving a command for high-speed machining will lead to an alarm (807 ILLEGAL FORMAT) under

a combined use of tool radius compensation for five-axis machining with tool tip point control

(Reference: EIA manual 29-3-5.2)

Instruction in

machining motion

Instruction in

preparation motion

for machining

Tool radius compensation for

5-axis machining

Tool tip point control

Table coordinate system

Program composition element

Serial No. 294060

Copyright (c) 2013 YAMAZAKI MAZAK CORPORATION. All rights reserved.

Loading...

Loading...