68 4 Tool Table

4.1 Tool Table

4.1 Tool Table

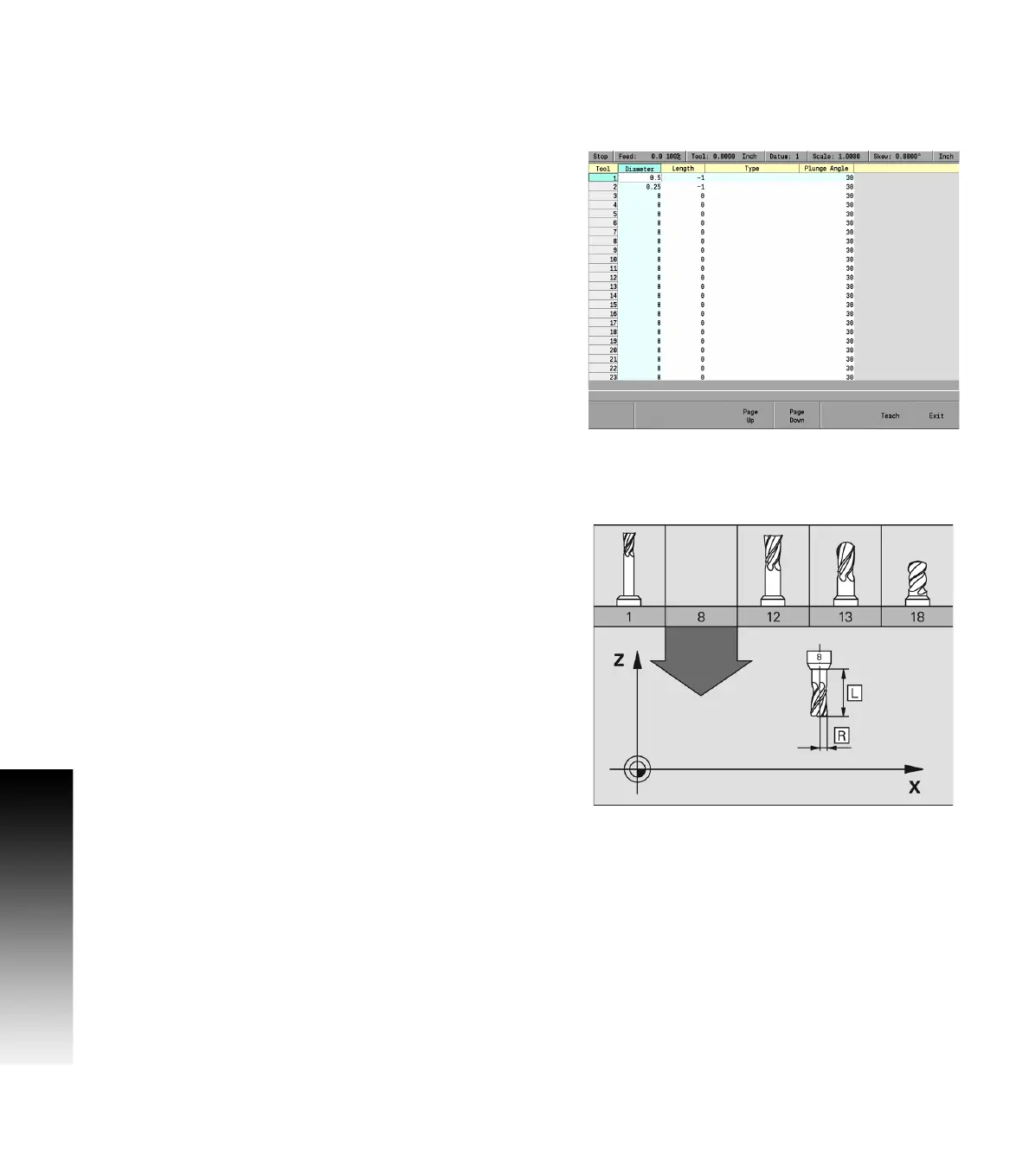

Overview

When the MILLPWR

G2

runs a program step that activates a tool, it

only activates the diameter, and length values on that row of the Tool

Table. The tool number, or tool type are not activated in dialogues that

have these fields.

Tool Table values are automatically converted to their inch or

millimeter equivalents when the MILLPWR

G2

mode is changed. All

typed values must match the current unit mode of the MILLPWR

G2

.

Define and store up to 99 tools on the tool table. Type of data stored

on the Tool Table is information specific to each tool.

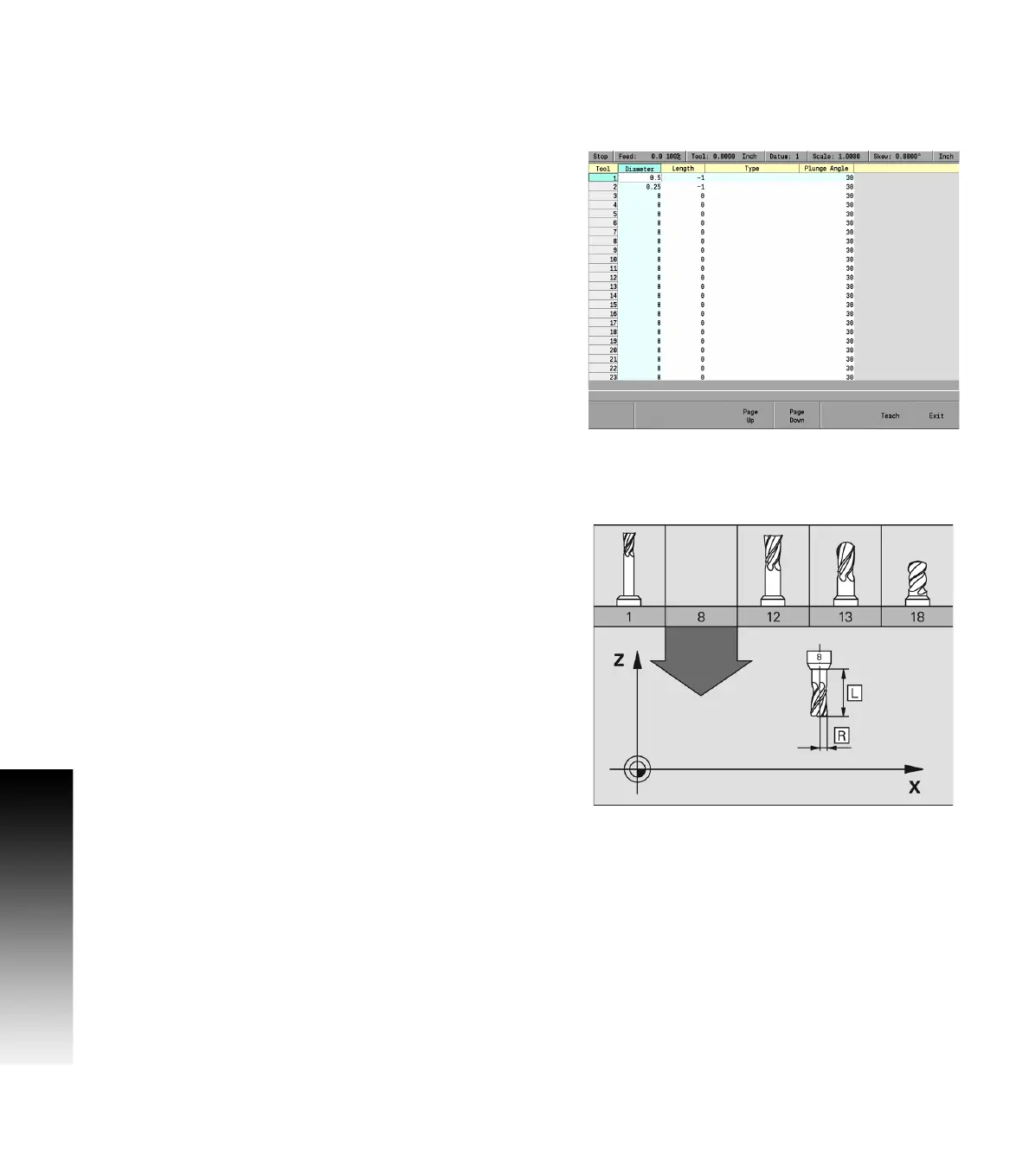

Tool compensation required data

You usually program the coordinates of path contours as they are

dimensioned on the work piece drawing. To allow the MILLPWR

G2

to

calculate the tool center path, e.g. the tool compensation, you must

also enter the diameter of each tool you are using.

Tool data can be entered either directly in the part program or

separately in the Tool Table. In the Tool Table, you can also enter

additional data for the specific tool. The MILLPWR

G2

will consider all

the data entered for the tool when running the part program.

Loading...

Loading...