Version 16.10 AF-6600 AF-5000 Series Install Manual 43

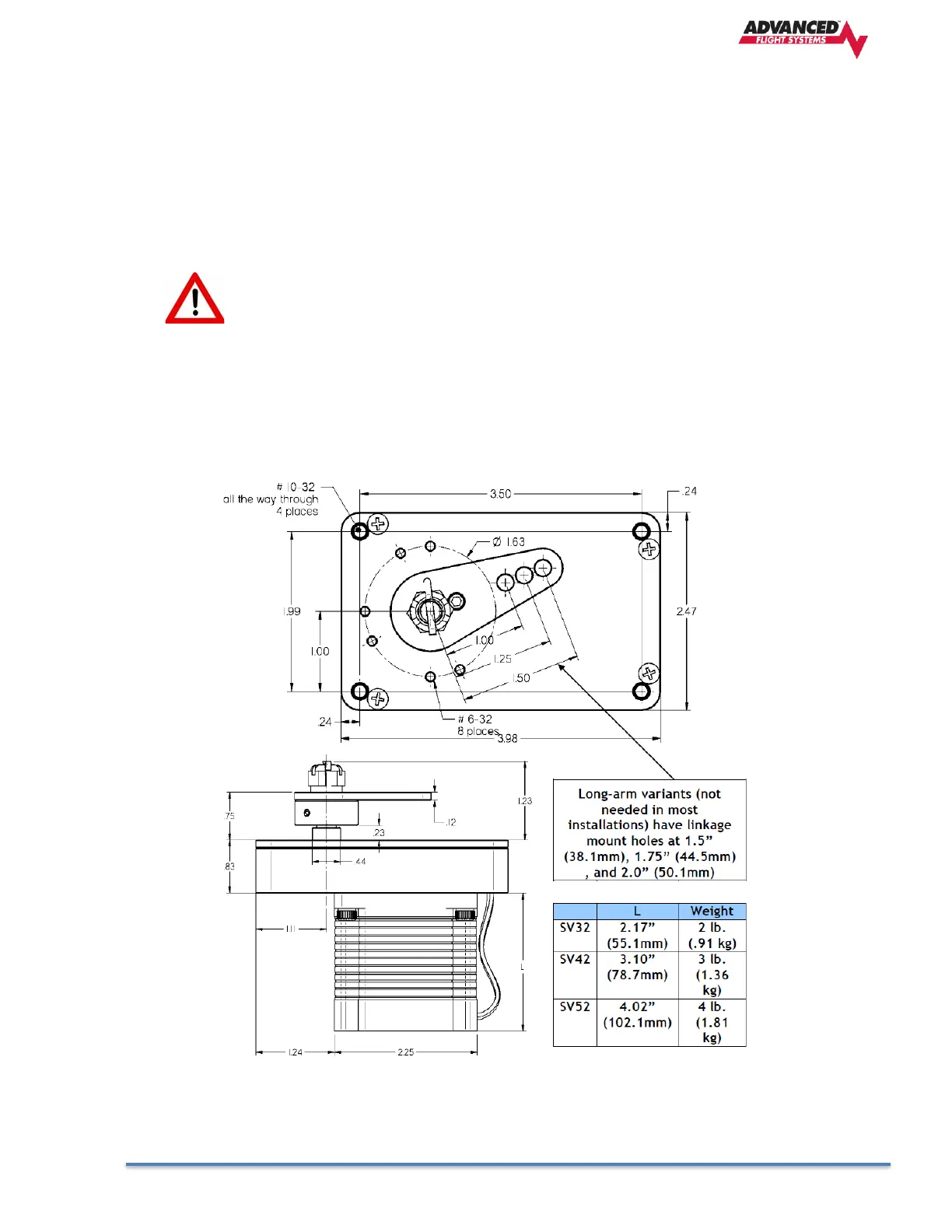

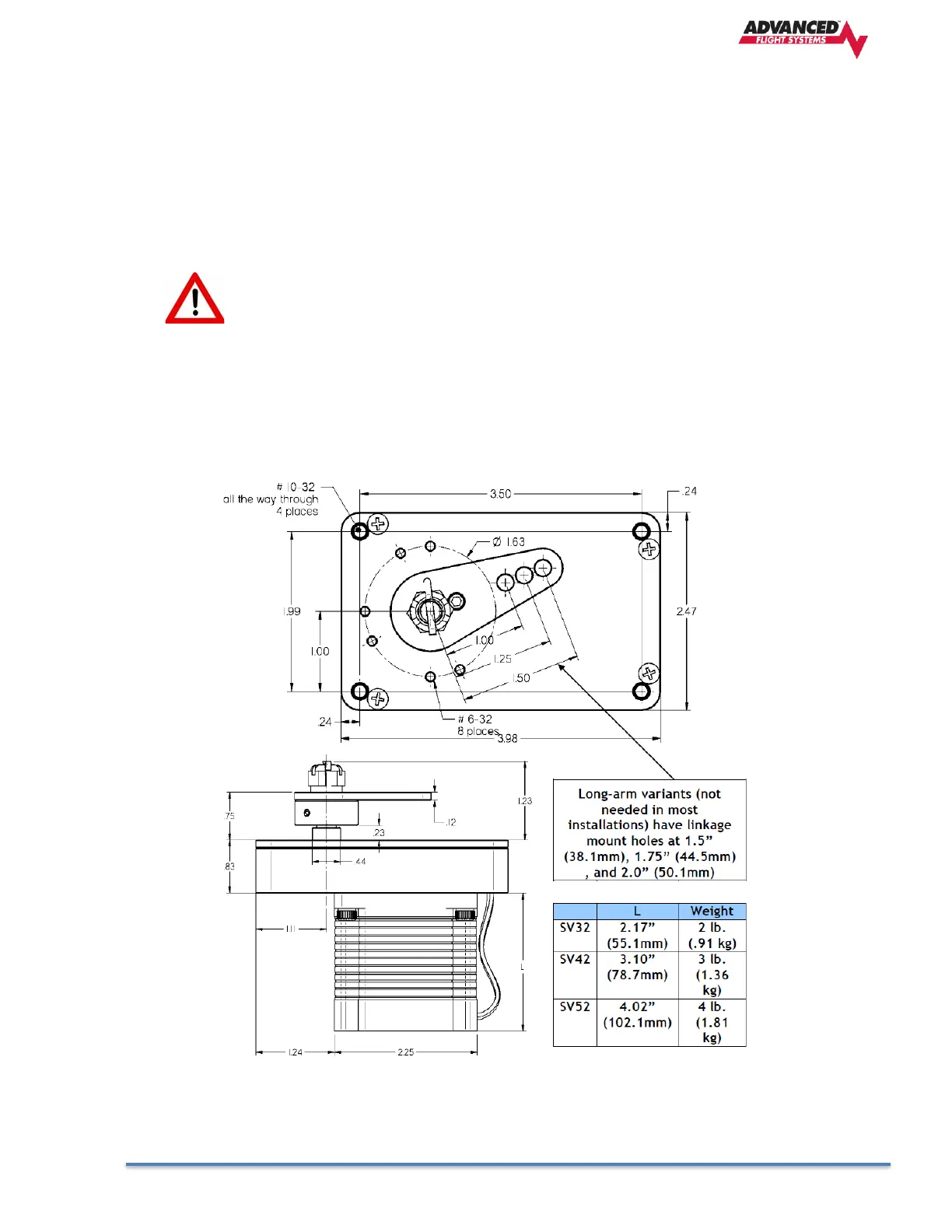

Once a suitable mounting point for each servo has been determined, the next step is

to fabricate a mount for the servo to attach to the aircraft. Generally this will be a

bracket made of sheet metal or corner stock. Dynon recommends using 6061 T6

aluminum with a minimum thickness of 0.050” for the best balance of strength to

weight. When fabricating a mounting bracket, refer to the servo dimensions below. Be

sure to leave ample room for the arm and attached linkage to move through a

complete range of motion without interference.

In normal operation, autopilot servos can reach temperatures that can be very

uncomfortable to, and perhaps cause burns to unprotected skin. Thus, servos

should be mounted in an area, or in such a manner to prevent accidental skin

contact. If mounting the servo in an exposed area is necessary, a shroud should be

installed (that doesn’t restrict ventilation) that protects against accidental skin

contact with the servos.

Push-Pull Servo Dimensions

Use the following dimensions (in inches) for reference when planning and implementing your

installation.

Loading...

Loading...