Version 16.10 AF-6600 AF-5000 Series Install Manual 44

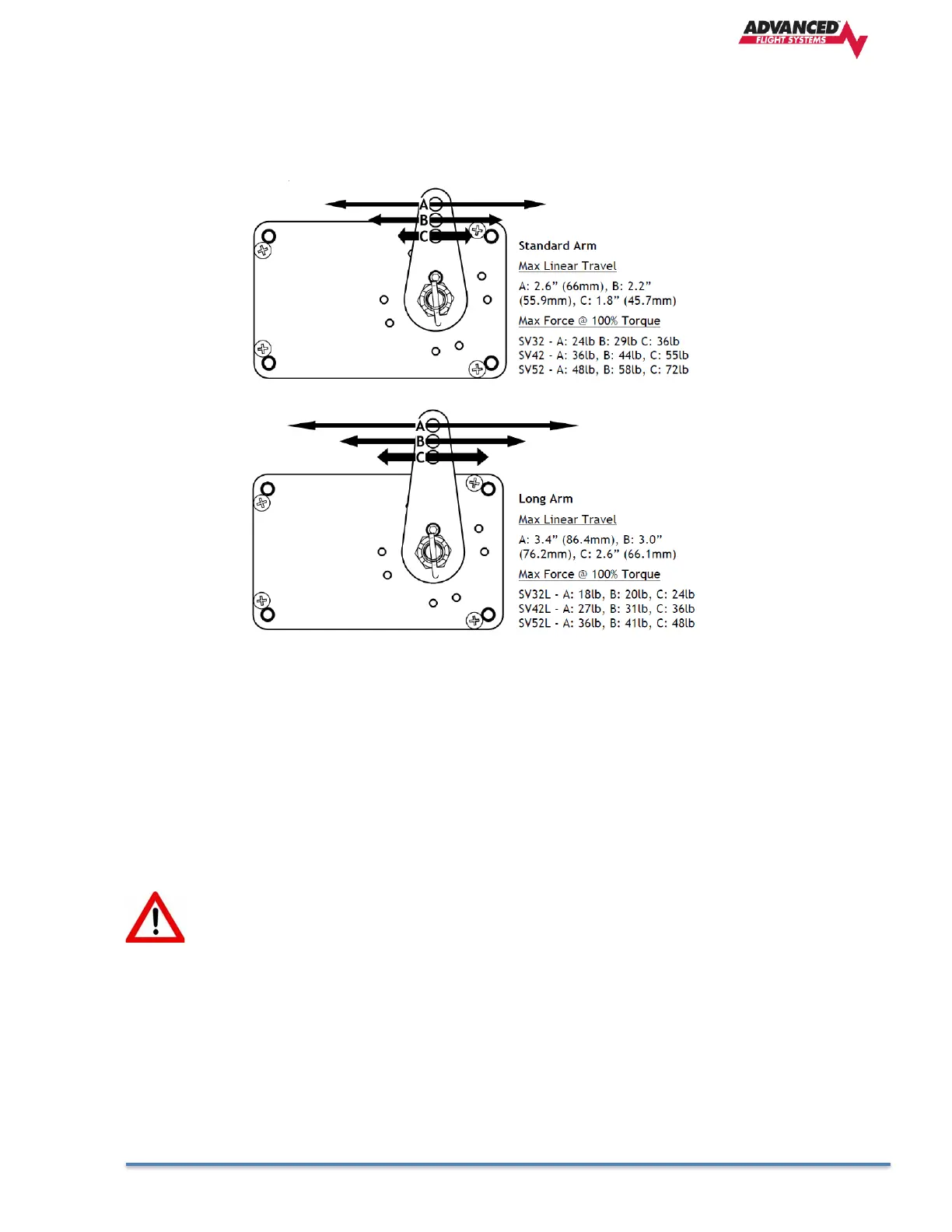

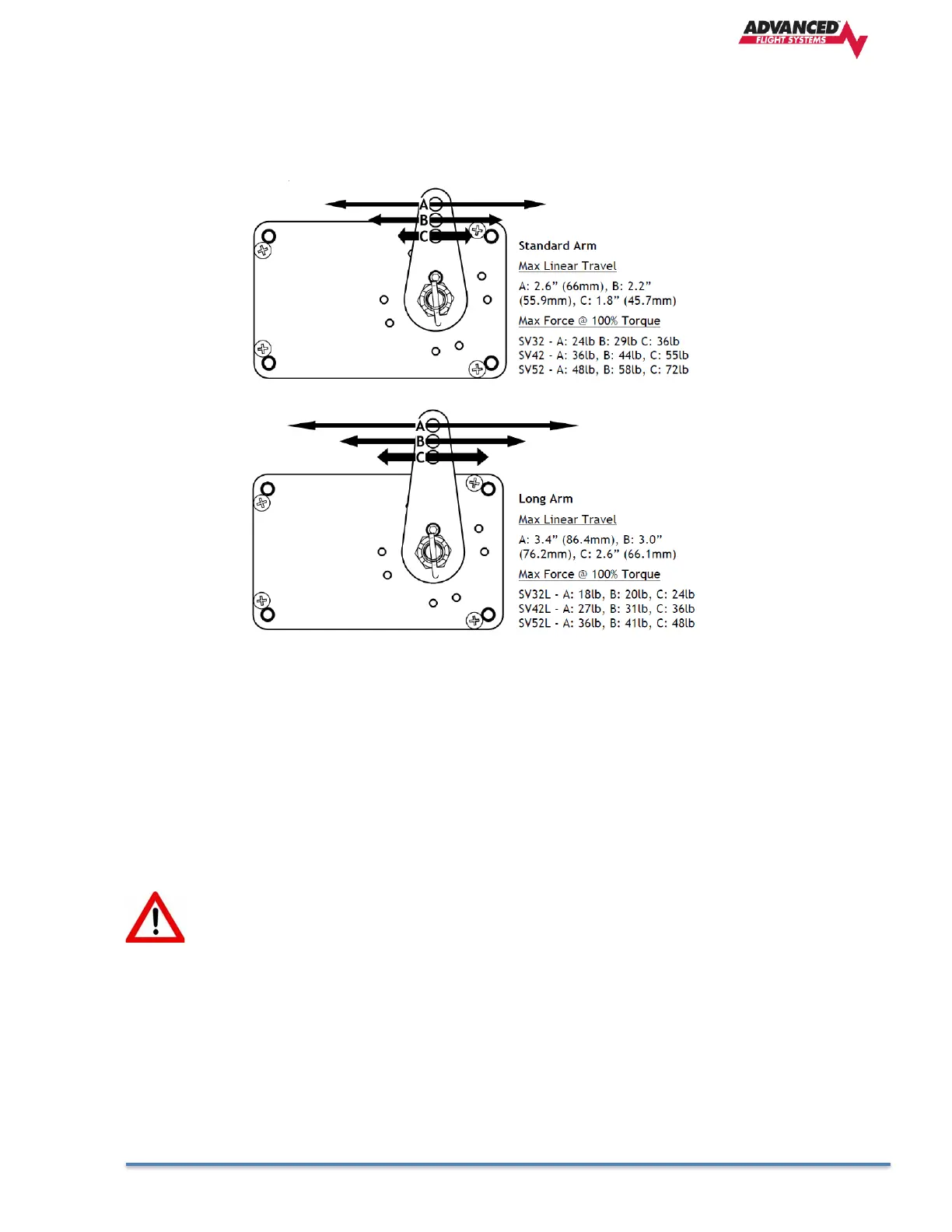

Linkage Mount Position Force and Travel

The two diagrams below illustrate the maximum travel and force available at each linkage mounting

point. As can be seen, the closer you mount the linkage to the shaft, the more force the servo can

deliver. However, this also means the travel of the arm is shorter.

Again, ensure that the servo arm is nowhere near going over-center throughout the entire range of the

control system.

The maximum linear travel specifications called out above denote the distance traveled by the location

on the arm such that it is 60° from center at maximum distance in either direction (e.g., the A hole on

the standard servo arm can linearly travel 1.3”(33mm) from center in either direction).

During installation, the linkage hardware must be connected to the servo arm such that the servo can

actuate the connected control surface while approaching, but not exceeding the called out maximum

linear travel specification. If too much slippage occurs during servo flight testing, it may be necessary

to use a stronger servo.

Each Dynon Avionics servo includes a precision-machined brass shear screw that pins the

servo arm to the servo arm attachment, providing an ultimate manual override. Servo

shear screws will break at the application of 100 inch-pounds of torque, at which point

the servo arm will travel freely. If the brass shear screw is broken during autopilot

installation or usage, do not replace it with a standard screw– contact Dynon Technical

Support (contact information at the beginning of this manual) for a replacement shear

screw. Instruction for replacing the shear screw can be found at

http://docs.dynonavionics.com.

Loading...

Loading...