000 299 119 5 - BA ROLLANT 240 - 250 - 254 - 255 14.2.1

Maintenance

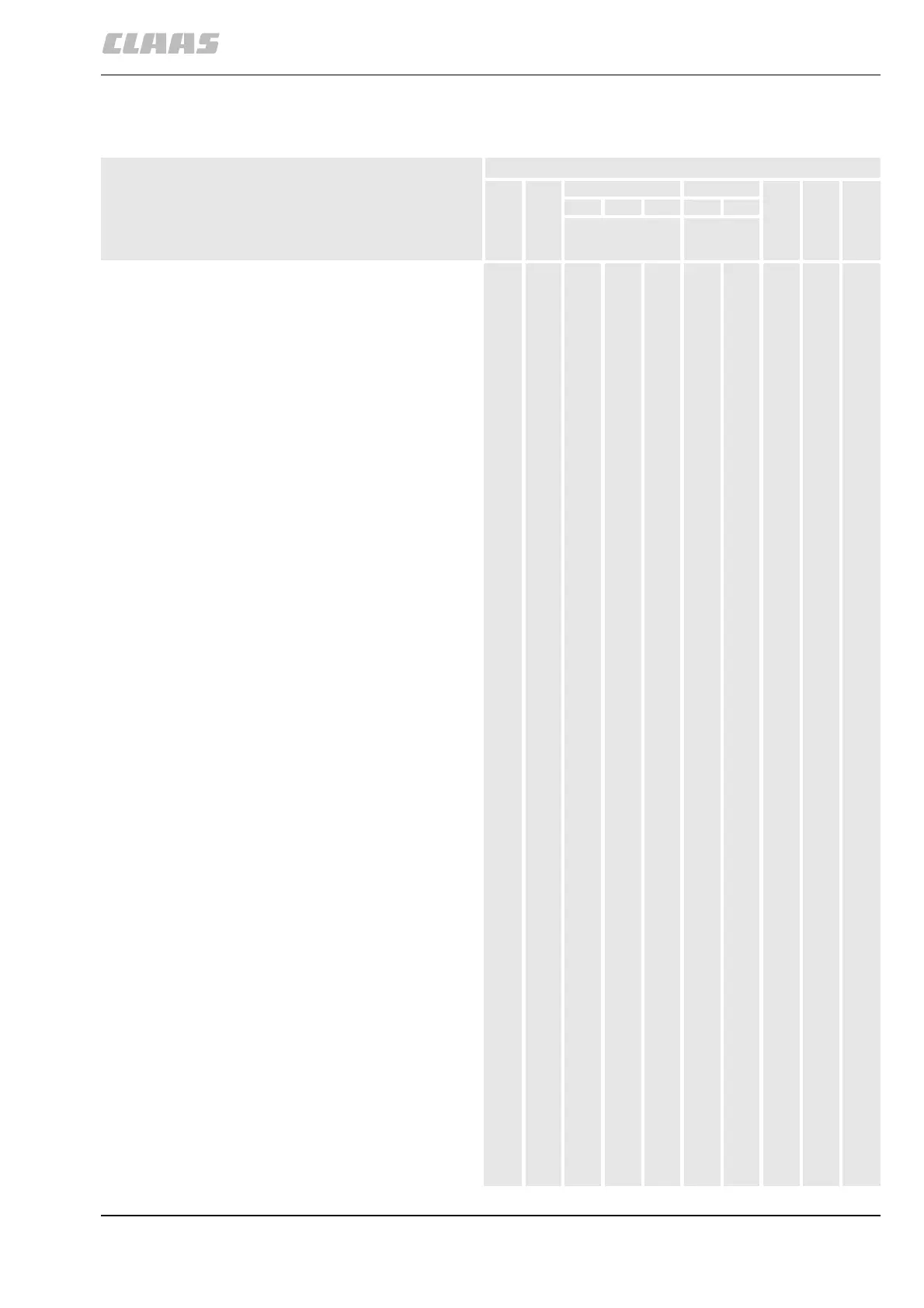

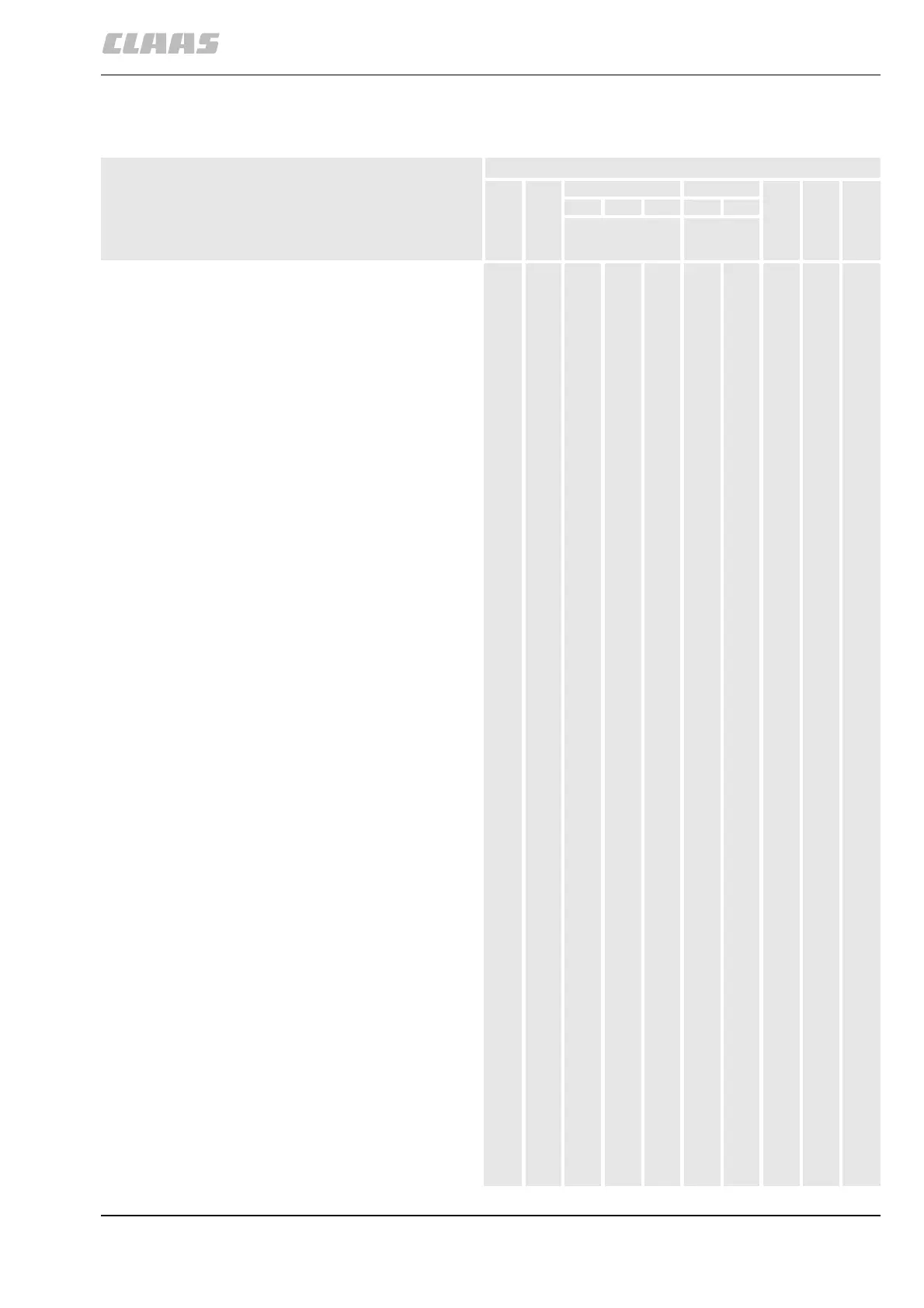

MAINTENANCE AND LUBRICANT TABLES

Maintenance table

Maintenance Operations Maintenance intervals

Daily

Before

starting up

After the first Every

Annually = every

500 hours of

operation.

As necessary

See page

10-15 50 150 50 100

hours of operation

hours of

operation

Angle drive gearboxes

– Check oil level _____________________________________________________________________

● __________________14.3.2

– Oil change ____________________________________________________________

● ____________________ ● _______14.3.2

Hydraulic oil filter

– Change the filter insert _________________________________________________________

● ______________ ● _______14.6.1

Drive chains

– Check tension, readjust if necessary ____________________________________________________

● __________________14.3.3

Wheels and tires

– Check hub clearance, adjust if necessary ____________________________________

● ______________ ● ________ ●

– Check the condition of the wheels and tires _______________________________________________ ●

– Check that air pressure of the tires is correct

(air pressure – see “Specifications”)_______________________ when using machine for the first time

● ______________ ●

Bolts

– Retighten wheel nuts

(torque settings – see “Specifications”) ________________________________

● ______________ ●

– Check clamping bolts of the hitch eye and drawbar,

tighten if necessary (torque settings – see “Specifications”) ________________

● ______________ ●

Check condition of the compressed air tubes and coupling heads ___________●

Clean dirt and pieces of straw from the baler,

especially the wrapping units _________________________________

●

Parts to be greased – see “Lubrication Plan”

Clean the rollers (Rollant 255)______________________________________________________________

● _________________ 14.7.1

Cleaning roller openings __________________________________________________________________

●

Maintenance

Loading...

Loading...