©2025 Copeland LP.

026-1803 R13 Supervisor I&O User Guide 9 - 49

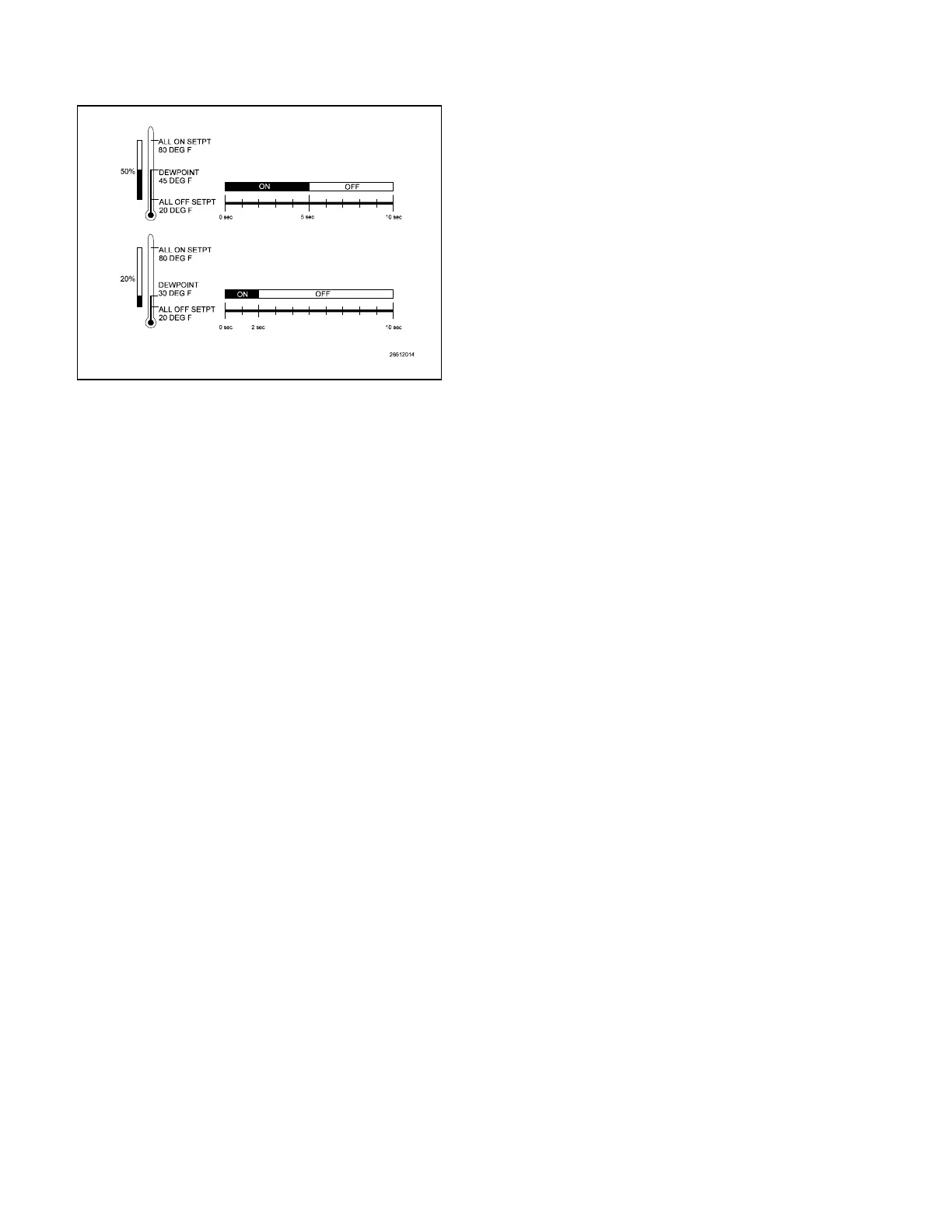

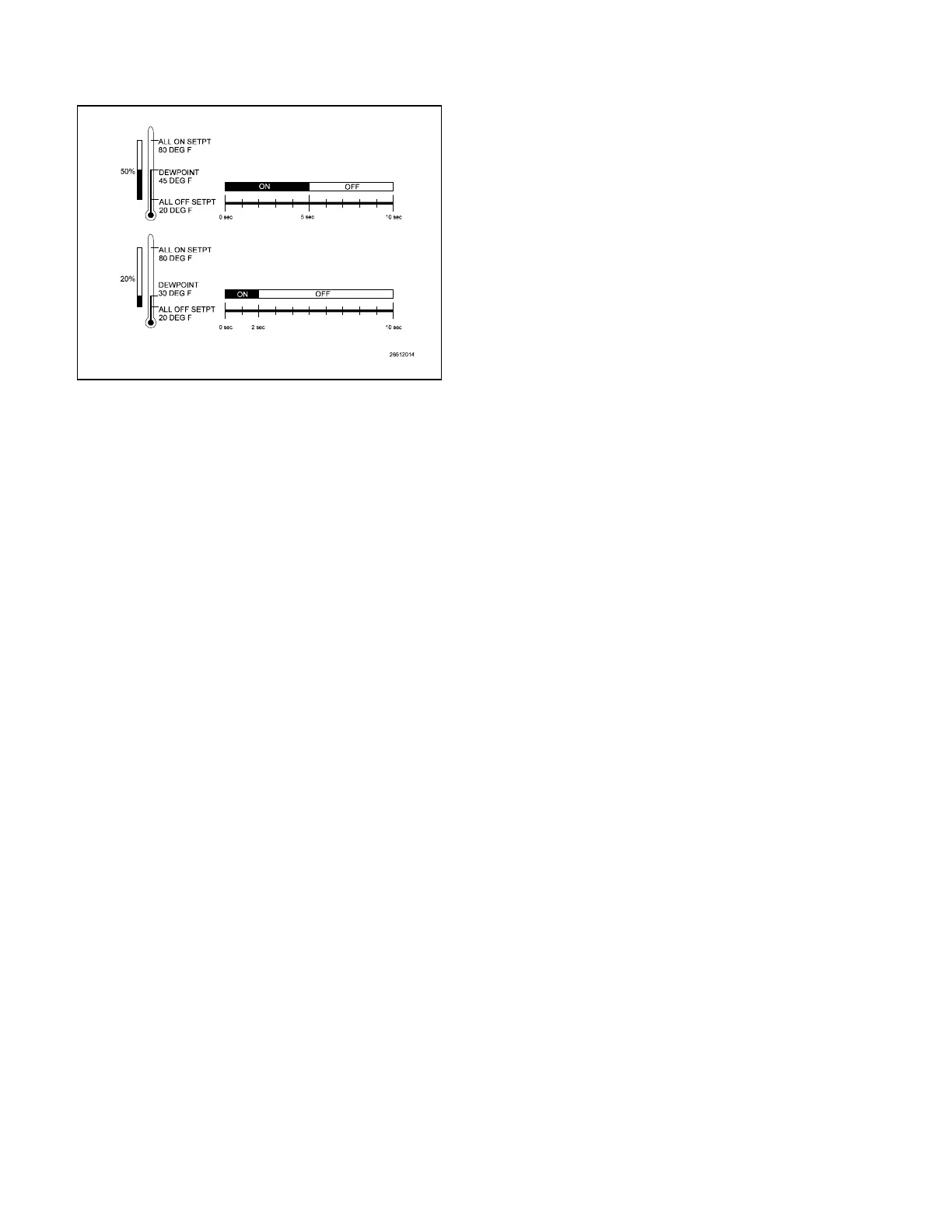

the percentage will lower to 20%, and the heaters will be on

only 2 seconds out of every 10.

9.36 Condenser Control

An air-cooled condenser consists of one or more fans that

blow air across a manifold of tubing to cool heated refrigerant

and condense it into a liquid. In an evaporative condenser,

water is sprayed across a condenser coil, which cools the

refrigerant as water is evaporated. Control of the evaporative

condenser is similar in ways to the air cooled strategy in that

the Condenser Control application uses PID control to

activate or deactivate fans (thus increasing or decreasing the

amount of evaporative cooling).

Air Cooled Condensers

An air-cooled condenser consists of one or more fans that

blow air across a manifold of tubing to cool heated refrigerant

and condense it into a liquid. The Site Supervisor controls

condensers by activating or deactivating fans in order to

maintain discharge pressure or temperature at or below a

chosen setpoint.

A Condenser Control application may use either of two

strategies to operate air cooled condensers: an air-cooled

strategy, or a temperature differential (T-D) strategy.

9.36.0.1 Air Cooled Strategy

The air cooled strategy uses a simple PID control loop that

compares a single Control In input to a PID setpoint. The

resulting percentage is used to activate the condenser fan(s)

necessary to bring the input value down below the setpoint.

Control inputs for air cooled strategies most commonly come

from a pressure transducer mounted on either the discharge

line, the condenser inlet, or the condenser outlet. However,

temperature sensor values will also be accepted.

9.36.0.2 Temperature Differential

Strategy

The temperature differential strategy attempts to keep a

minimum amount of difference between the temperature of

the refrigerant and the ambient outside temperature.

This strategy begins by determining the temperature of the

refrigerant coming into the condenser. This can be supplied

by either a temperature sensor or pressure transducer located

near the condenser inlet; if it is a pressure transducer, its value

will automatically be converted to a temperature value based

upon the type of refrigerant.

The refrigerant temperature is subtracted from the value of an

ambient air temperature sensor. The result is the temperature

differential. It is this differential value that is compared to the

PID setpoint for the purpose of determining the amount of

total fan capacity to activate.

9.36.1 Evaporative Condensers

In an evaporative condenser, water is sprayed across a

condenser coil, which cools the refrigerant as water is

evaporated. Control of the evaporative condenser is similar in

ways to the air cooled strategy in that the Condenser Control

application uses PID control to activate or deactivate fans

(thus increasing or decreasing the amount of evaporative

cooling).

Like air-cooled condensers, evaporative condensers may be

controlled by discharge pressure or temperature. They may

also be controlled by water sump temperature. In addition,

each evaporative condenser may have up to 16 “override”

sensors (either temperature or pressure) that allow the

condenser to be overridden to fast recovery mode.

9.36.2 Fan Control

Condenser Control applications can control three different

kinds of fans: single-speed fans (up to 12 stages), two-speed

fans, and variable-speed fans. All fan types are controlled by

PID control; in other words, the Condenser Control

application generates a percentage from 0% to 100% that

corresponds to the amount of total fan power that should be

active.

Single-speed fans translate the PID percentage into a

percentage of total fan capacity. For example, if the PID

percentage is 75%, then 75% of all condenser fan stages will

be ON.

Two-speed fans use Cut In/Cut Out setpoints to translate the

percentage into an OFF, LO, or HI fan state.

Figure 9-22 - Illustration of Anti-Sweat Control

Loading...

Loading...