©2025 Copeland LP.

026-1803 R13 Supervisor I&O User Guide 7 - 4

7.2.3.1 I/O Network and MultiFlex RTU

Setup on Serial Port

1. Navigate to serial port configuration screen, select an

unused port and configure it as an I/O network port.

2. Configure the baud rate of the I/O network port, then

select MultiFlex RTU from the supported board types for

this port. Set the number of board needed to setup, click

Save to add the RTU devices. RTU board status will

appear “Online”.

3. Navigate to the “HVAC - RTU_0X” device status screen

through the site map, the status screen

displays the following sections:

• General

• Inputs

• Outputs

• RTU Outputs

4. Click Details on the status screen, the system will display

the properties of the RTU board by the properties group.

You can now view and configure the properties of the

RTU board.

5. After configuring the properties, the new values can be

sent to RTU application on the Supervisory Controller

and RTU board on the I/O network. The RTU board can

now work correctly on the controller.

7.2.3.2 Creating an Instance of RTU

Application

You can create an instance of RTU application even if the

RTU board is not connected to the Supervisory Controller,

however the board status is displayed “Offline”.

If the RTU board is connected to the supervisory controller

through the I/O network, the supervisory controller should

find the RTU board and its property values and should be

read on the controller through the I/O network.

7.2.3.3 Deleting/Checking Status of RTU

Board

You can navigate to Network Summary screen to do the

following operations:

1. View all the devices connected to the Site Supervisor

from the I/O network and its online status.

2. Delete a device.

3. View the I/O network traffic status.

4. Navigate to the summary screen of a specific device.

7.2.3.4 Zone Management

You can associate an RTU application with a zone. Zone is a

group of RTUs and/or AHU (air handling unit) applications

that shares the same heating, cooling, dehumidification

setpoints, and other control parameters. The primary purpose

of zone control is to maintain a specific temperature and

humidity level throughout a wide area using multiple rooftop

units.

When an RTU application is associated with a zone, some

inputs of RTU application should use the output values from

zone. These are the property mapping list:

7.2.3.5 Scheduling

Daily (from Monday to Sunday) schedules of Occupied/

Unoccupied state can be set and send to the RTU board.

7.2.3.6 Alarming

Alarms generated from RTU board will be received and

reported by Alarm management in Site Supervisor. You can

configure the attribution, type and category of the alarms

generated from RTU board.

Any reset or clear actions performed on the UI is forwarded to

the RTU board.

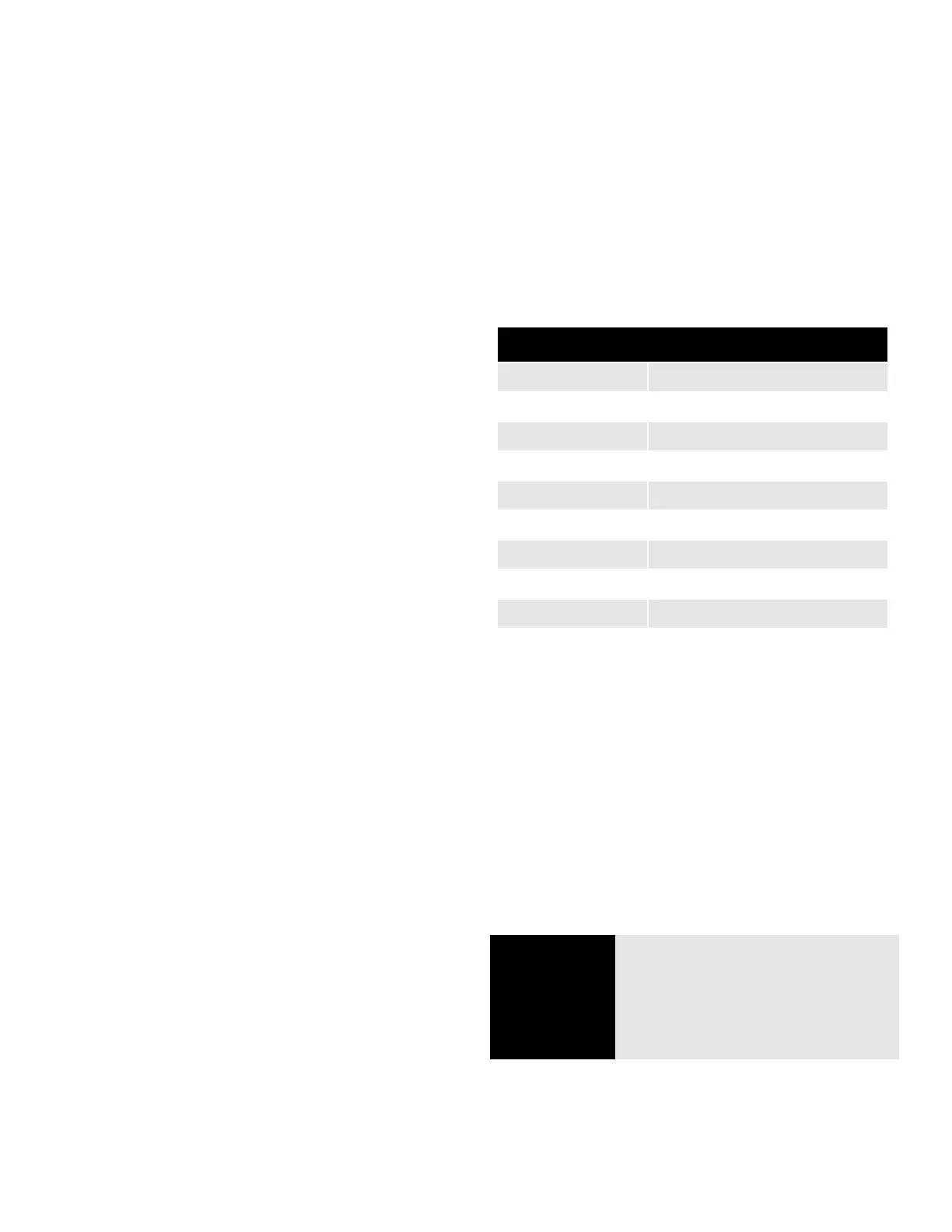

Table 7-3- RTU and Zone Property Mapping List

RTU Inputs Zone Outputs

ZONE OCC ZONE_OCC_STATE

ZONE TEMP ZONE_TEMP_OUT

ECONMIZE ZONE ECON OK

DEHUMDIFY ZONE DEHUM ACTIVE

OCC HEAT ZONE HEAT OCC OUT

UNOCC HEAT ZONE HEAT UOC OUT

OCC COOL ZONE COOL OCC OUT

UNOCC COOL ZONE COOL UOC OUT

OCC DEHUM ZONE FB HUMID STPT

SEASON ZONE_SUM_WIN_MODE_OUT

NOTE

NOTE: The RTU does not have the

capability of resetting individual

alarms. All alarms on the RTU will be

reset or cleared by the RTU if anyone

resets or clears the alarms in the

Supervisory Controller.

Loading...

Loading...