©2025 Copeland LP.

026-1803 R13 Supervisor I&O User Guide 9 - 63

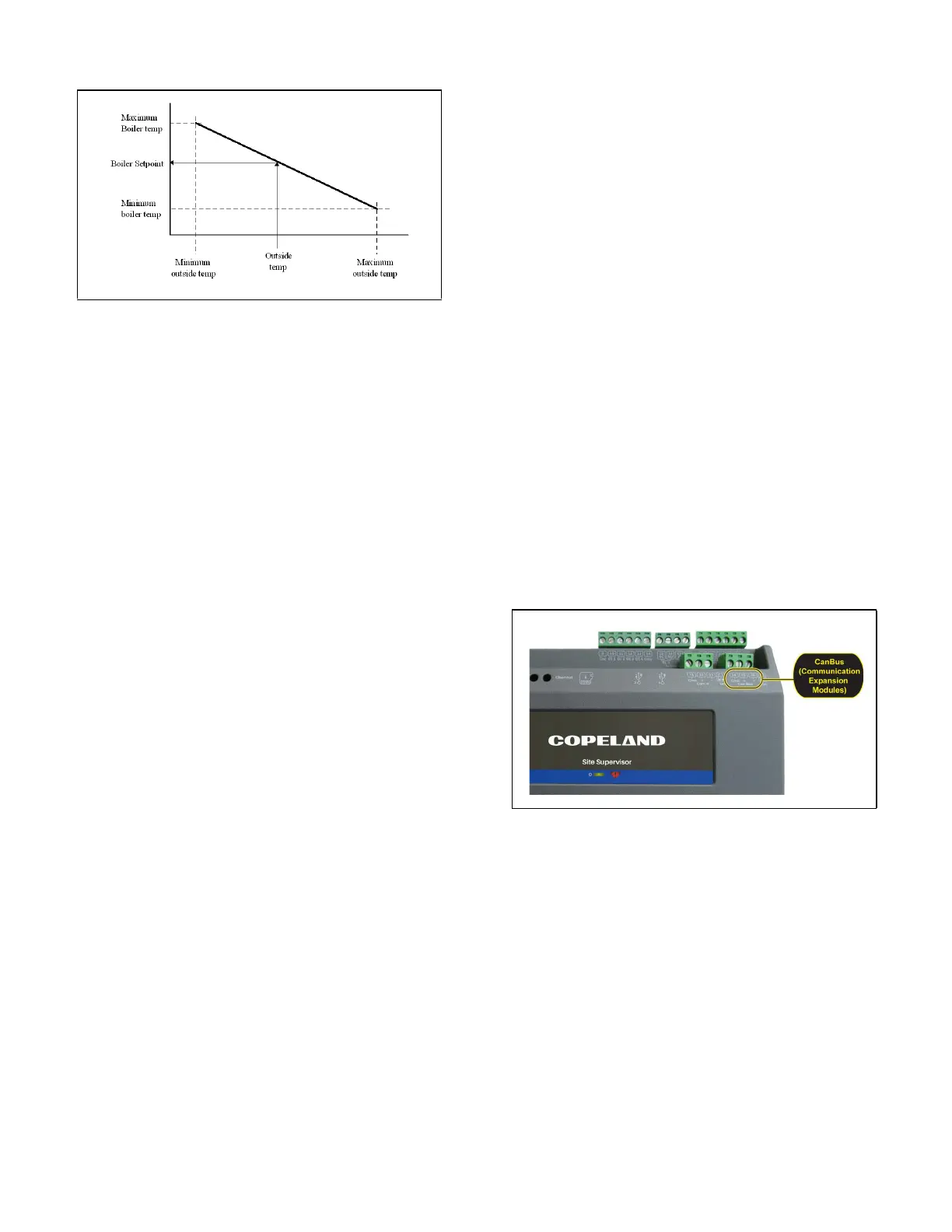

9.45 Boiler

The Boiler can be controlled two ways, via the boiler

temperature or the boiler pressure. Current outside air

temperature calculates a new boiler control setpoint. If the

boiler temperature (or boiler pressure) is less than the

setpoint value, the boiler is turned ON. Otherwise it is turned

OFF. The algorithm will work in an inverted fashion if the

Minimum Outside Air Temperature is greater than the

Maximum Outside Air Temperature. An Outside Air

Temperature Boiler On and an Outside Air Temperature Boiler

Off can be defined. If the outside air temperature is lower than

the Outside Air Temperature Boiler On, the boiler is turned ON.

If the outside air temperature is higher than the Outside Air

Temperature Boiler Off, the boiler is turned OFF. If defined, the

Outside Air Temperature Boiler Off must be greater than the

Outside Air Temperature Boiler On.

Boiler Alarms

There are four advisories generated by the Boiler

Application:

• High Temperature

• Low Temperature

• High Pressure

• Low Pressure

Each advisory will have an associated type, priority, and

delay.

9.46 XJ Condensing Unit

The XJ Condensing Unit is a device for controlling the XJ

Condensing Unit, also known as the XJ Scroll Unit. The

Supervisory Controller will perform tasks for coordination,

logging, alarming, and access for configuration and status.

The XJ Scroll Unit follows the typical MODBUS

commissioning method. In the XJ Scroll Unit, the device

address is determined using dip switches on the device itself.

The range of allowable addresses is 1 through 255.

Copeland Scroll™ outdoor condensing units provide scroll

compressor technology with advanced diagnostic controls

to ensure reliable performance and operation in food service

applications. Protection and diagnostic features are

controlled by an electronic integrated control board. This

control board provides base control functions related to

temperature controller, defrost, evaporator fan control,

compressor protection (for example, current overload, phase

reversal, liquid/vapor injection control, self diagnostics and

warnings). These error codes can be seen by an LED display

for troubleshooting and maintenance. Medium and low

temperature units are available in single and three phase 208/

230 volts. The -002 and -012 BOM product is approved for

operation in ambients from120°F to -10°F. For more

information, refer to the Copeland Scroll™ Outdoor

Condensing Unit literature P/N AE5-1377 R3.

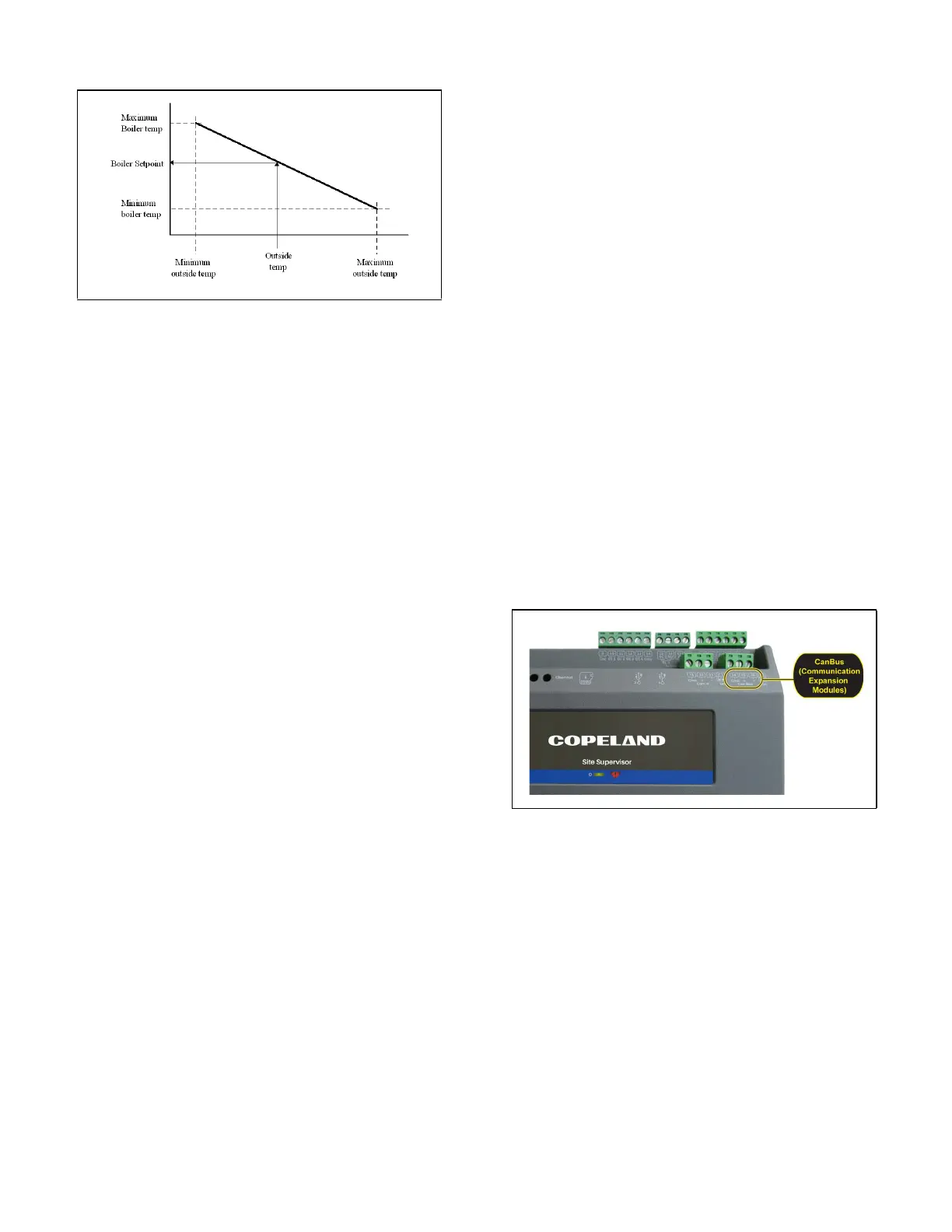

9.47 CAN Bus - IPX (Expansion Module)

The IPX boards provide expansion I/O for the Supervisor.

Pulsing logic is now supported. When selecting Digital, the

relay works as normal. When Pulse is selected, relay pulsing

logic is applied. The relay will cycle periodically (turns ON and

keeps ON for a specified period of time), and the CfgRL0x

Period; CfgRL0x_OnTime parameters become available.

For the CfgRL01 OnTime parameter, when Pulse is selected,

this parameter specifies the duty cycle (the ON percentage of

the cycle period with a range from 0 to 100%). For the

CfgRL01 Period parameter, when Pulse is selected, this

parameter specifies the entire cycle period.

Figure 9-26 - Temperature Ranges

Figure 9-27 - Can Bus Expansion Module

Loading...

Loading...