©2025 Copeland LP.

026-1803 R13 Supervisor I&O User Guide 9 - 58

9.41 Loop/Sequence Control

The Loop Sequence Control application’s main function is to read the value of an analog input, compare the value to a setpoint,

and generate a single analog output value. This output value is represented in three different forms: a single analog value from

0% to 100%, up to eight digital stage outputs, and a digital pulse width modulation output.

The output value(s) are generated by a PID Control cell, which takes into account both the input’s instantaneous value and its

rate and direction of change. The PID Control algorithm is similar to the PID algorithm used by Pressure Control, except the Loop

Sequence Control application is designed to be used in a wider array of applications.

How To Add a Loop/Sequence Control Device on the Supervisor:

1. From the Home screen, click the Control Inventory icon (box). Click the drop-down arrow for Add Control in the appropriate

category and select from the list.

2. Select the Control or Application Type - Loop/Sequence Ctrl, enter the Quantity, Control Name and Serial Type. Note that

Serial Type information can be enter later. Click Save to add the application.

3. A Confirmation box will appear saying that the application is successfully added to the system, click Close or Edit these

controls.

4. The system will display the new application(s) on the Site Summary screen.

5. Click the Loop/Sequence Control application panel box to view the application.

6. The system will display the Loop/Sequence Control application parameters.

7. The user can view and configure the properties of the application by setting the Edit Mode to ON on the screen drop-down

arrow on the upper right of the screen.

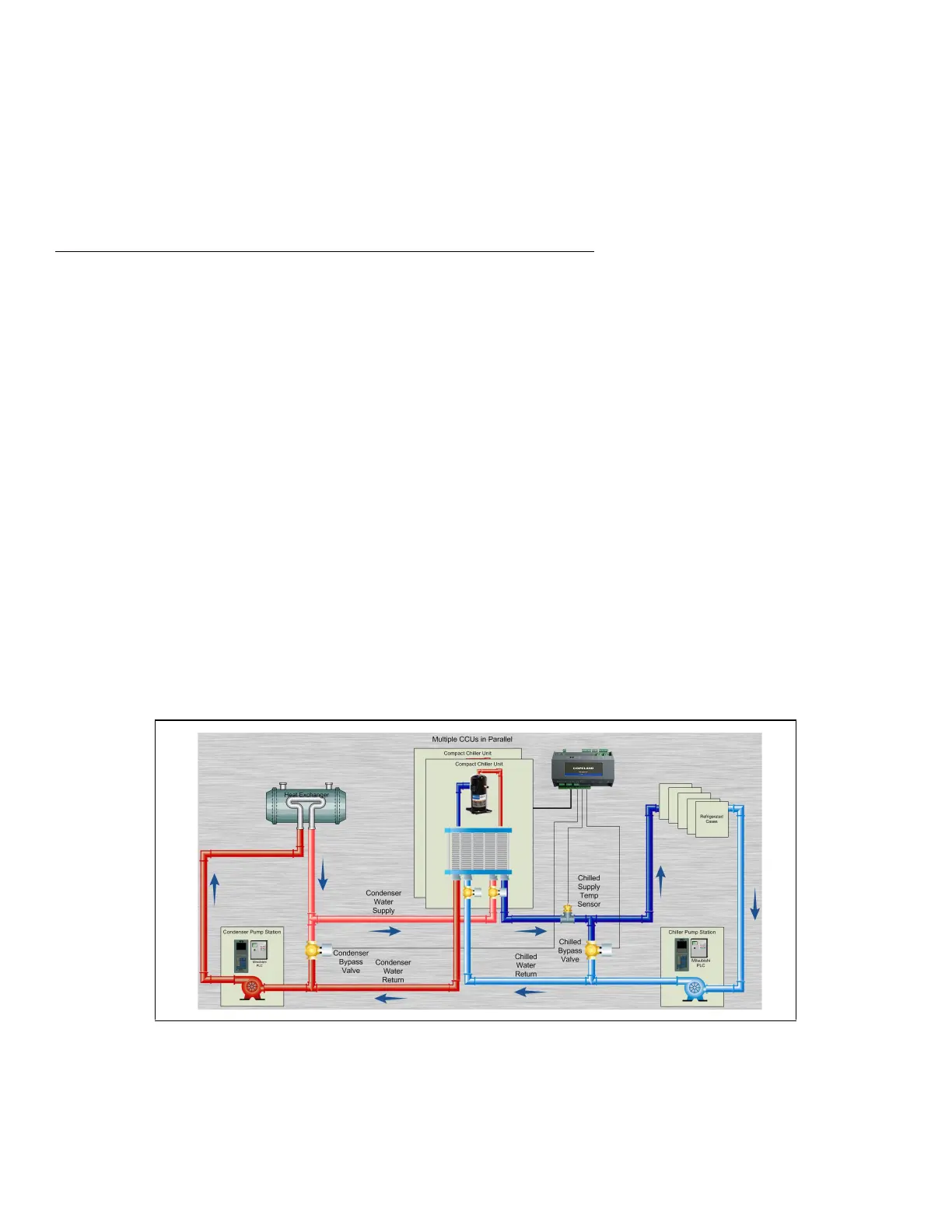

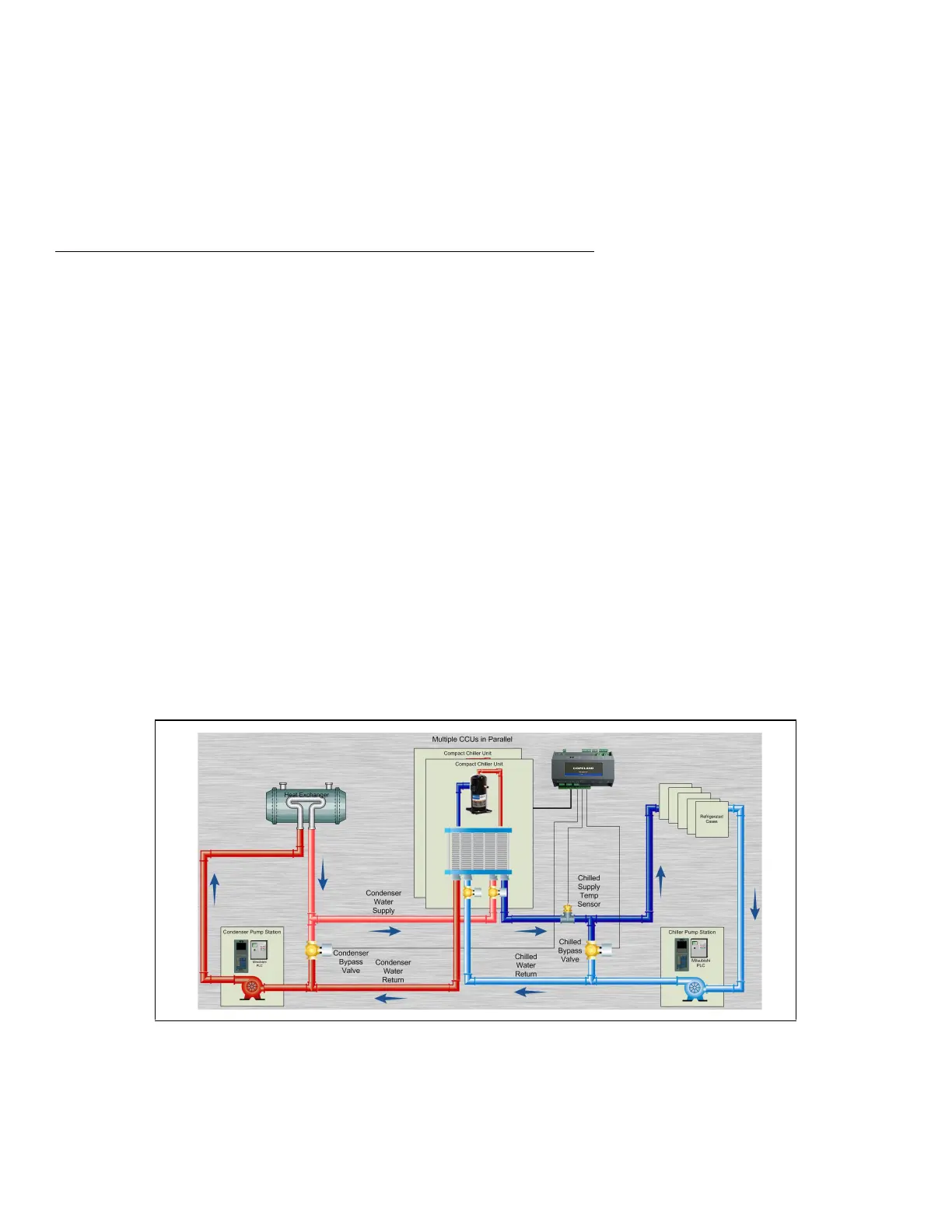

9.42 Modular Chiller Control

The Modular Chiller Control is available for the Supervisory Controller version 2.12 and above.

A Modular Chiller Control is made up of a single compressor connected to a brazed plate heat exchanger that provides a chilled

water and glycol mixture for cooling display cases and coolers. Multiple Modular Chillers are connected together to meet the

capacity requirements of the system.

Modular Chillers are designed to provide cooling by paralleling the hydronics side of the secondary system instead of the

refrigeration side of the system. These units also use a water and glycol mixture as a condensing fluid for compressor heat of

rejection. This design eliminates the long refrigerant piping runs thereby significantly reducing refrigerant charge.

Figure 9-25 - Compact Chiller System

Loading...

Loading...