• Live plot - Select Instant Spectrum or Average Spectrum to view the last measurement or

the average of all the measurements.

• Type of average - Set the method to calculate the average. The sections below list

the type of averages available.

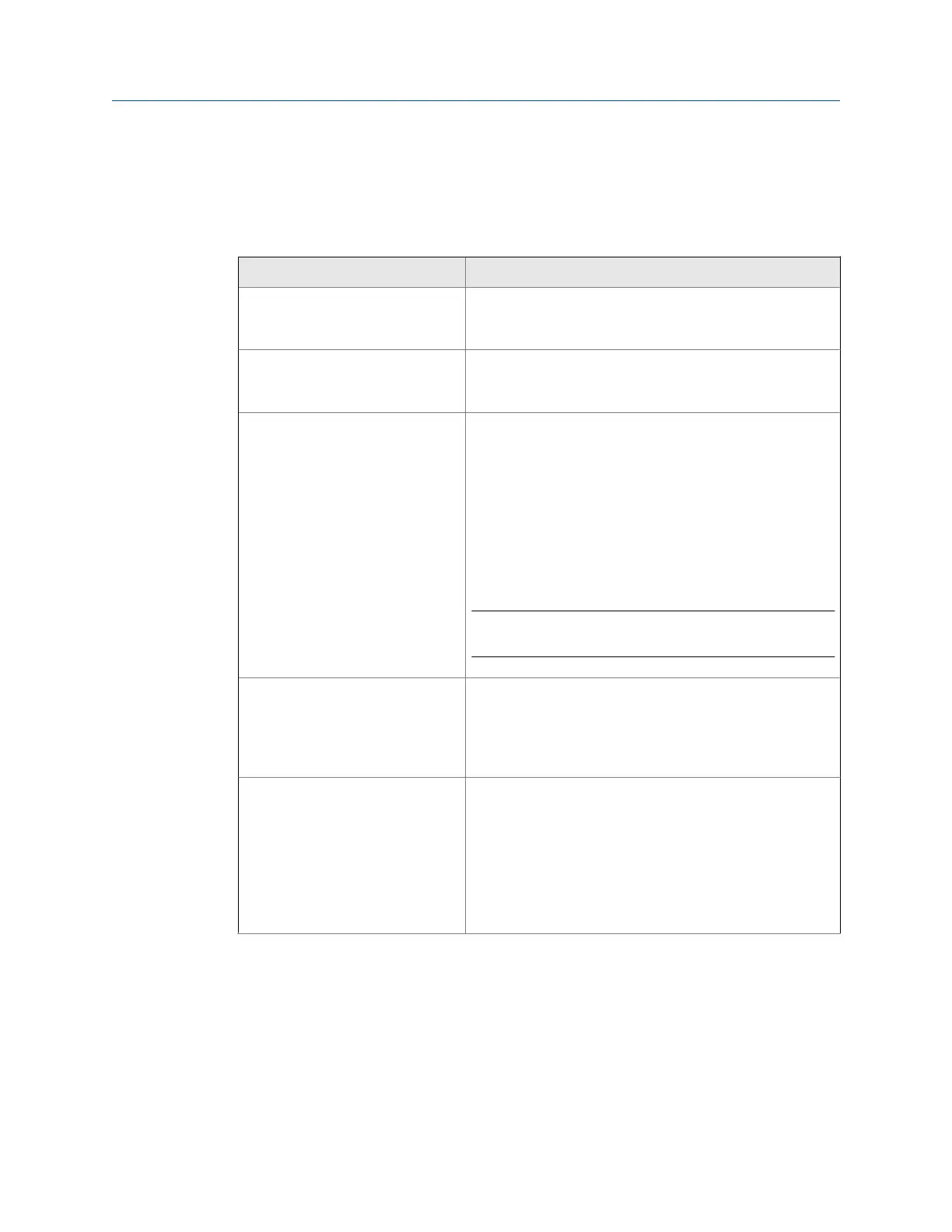

Option Description

Normal Average Add the power in each frequency line and divide by the

number of averages. Normal Average is suitable for most

measurements.

Peak Hold Average Display the largest amplitude of each spectral line. Use this

option during a machine coast down or to monitor random

fluctuations such as steam whirl or oil whirl.

Synchronous Time Remove the vibration of other machines from the signal, so

only the vibration from the reference machine remains. The

analyzer synchronizes each data sample with a tachometer

pulse, computes the average, and creates the spectrum

from the averaged waveform.

Use Synchronous Time when you need data directly related to

the turning speed of a specific shaft, or when several

machines or shafts on one machine turn at slightly different

speeds.

Note

A tachometer is required with this mode.

Order Tracking Monitor machines where the speed is changing during data

collection. Order Tracking helps normalize data so it does not

look smeared. You must use a tachometer and a reference

pulse. A tachometer pulse controls the data acquisition rate

to account for variations in machine RPM.

Negative Average Dynamically subtract one spectra from another while the

machine runs. Negative Average reduces the number of

spectra and compares the results with the results of a

normal averaging or with bump test data to help isolate

potential problems. The larger the number of spectra used

for averaging, the more the noise spikes in vibration signals

are reduced, and the more accurately true spectral peaks are

represented.

Analyze and Advanced Analyze

120 MHM-97432 Rev 7

Loading...

Loading...