10.16.4 Identify the correction planes

You can balance a rotor system exactly in N+2 planes (where N = the number of shaft

criticals below operating speed). Most mechanical systems are designed to operate below

their first shaft critical, so use 0 + 2 = 2 planes. Virtually all systems operate below their

fourth critical, so use 3 + 2 = 5 planes. Sometimes a single shaft has only two balance

planes, which normally allows an acceptable balance compromise, even if not exact.

Consider the following:

• The vendor may supply standard positions, such as balance rings.

• For a uniform rotor operating below the first critical, locate a single plane anywhere

for an adequate balance.

• If the rotor operates above the first critical and you use two-plane balancing, locate

the correction planes 25 percent of the distance between bearings.

• For non-uniform rotors, apply the correction weights first to the planes with the

greatest mass moments of inertia.

• Do not add correction weights at any location that affects the rotor stiffness or

modifies the aerodynamics or flow of the system.

10.16.5 Troubleshooting balancing

When field balancing does not give the desired results, it may be due to measurement

errors, weigh placement errors, vibration caused by something other than imbalance, or

lack of understanding of rotor dynamics of system.

If any of the following items occur during the balance procedure, you may not be able to

balance the equipment.

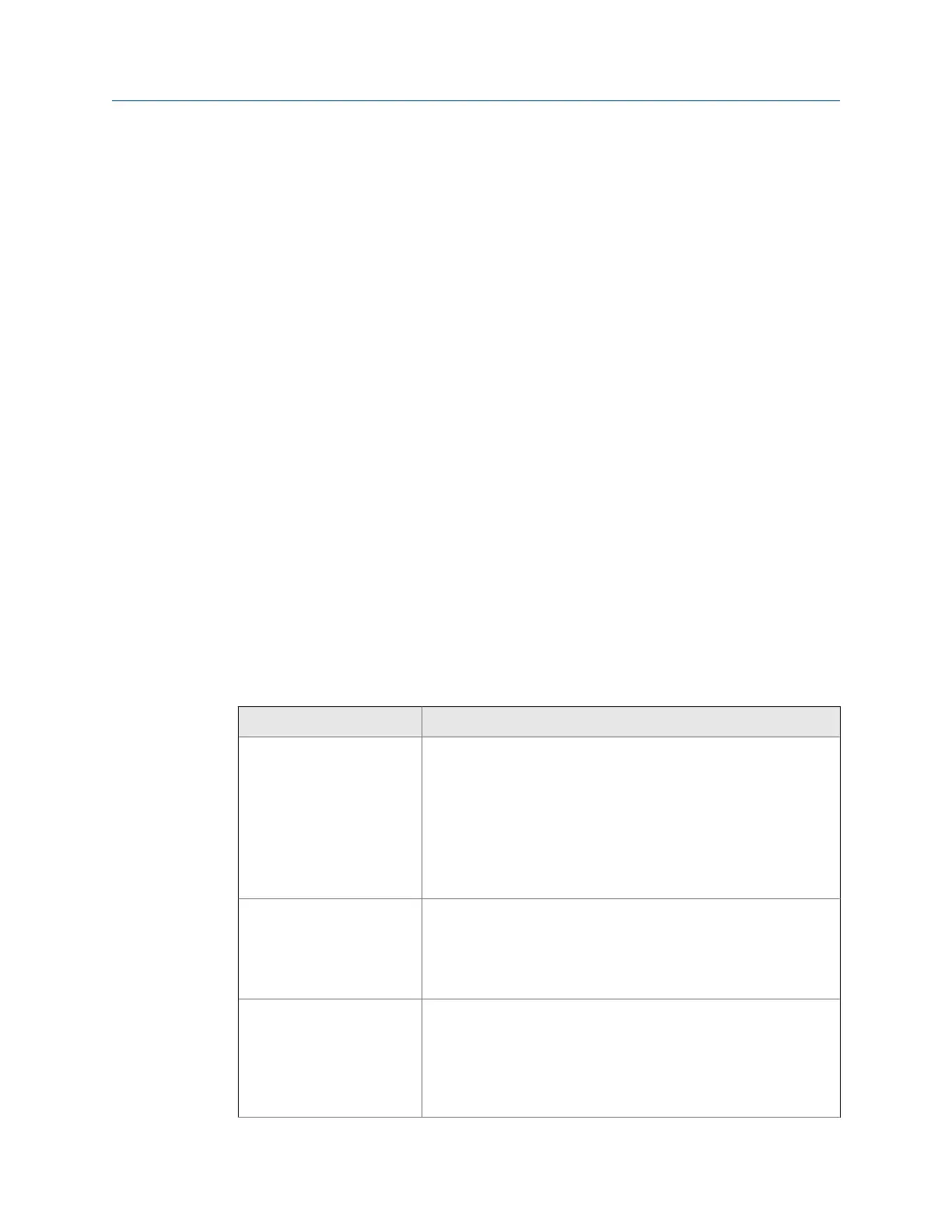

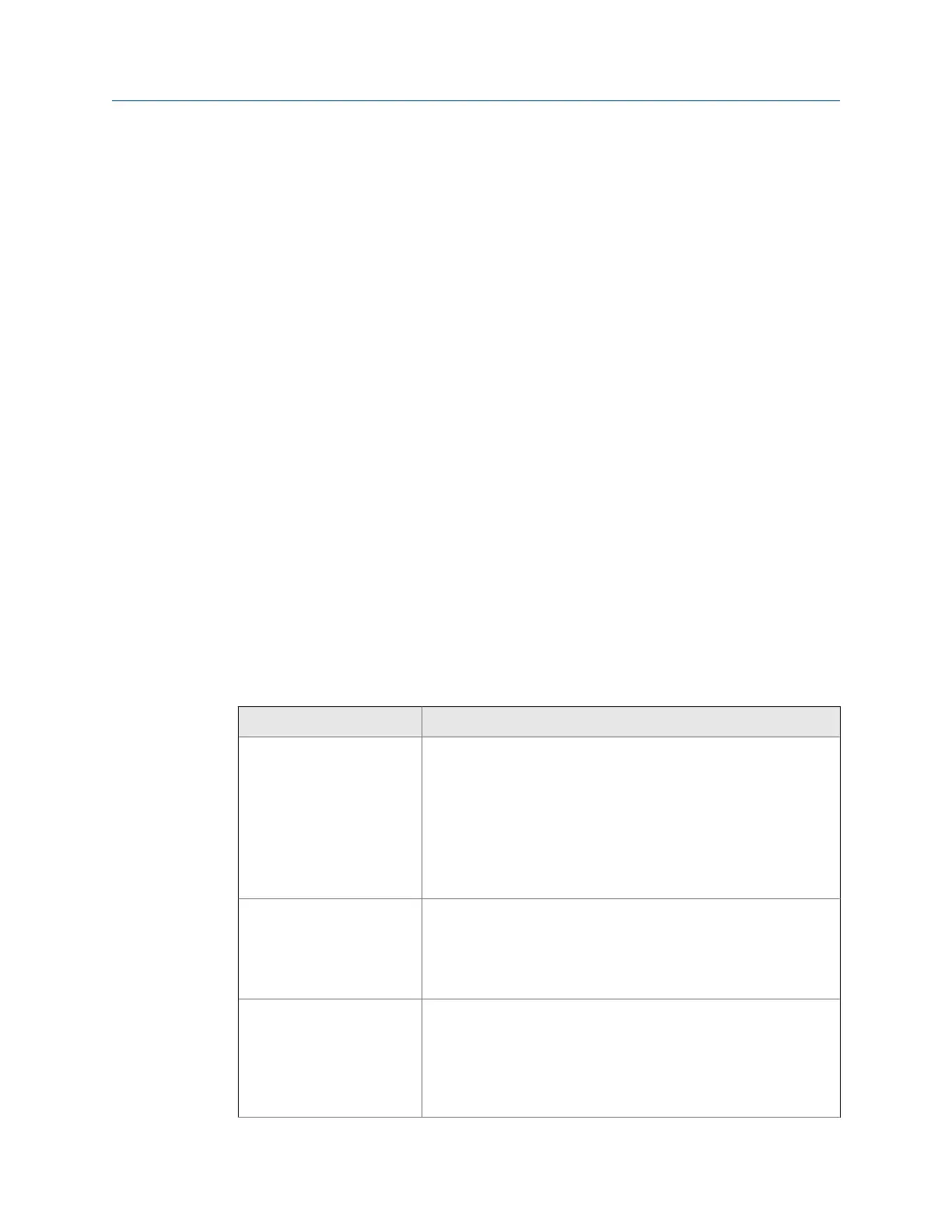

Issue Potential solution

Tachometer readings are

unsteady.

Possible causes:

• Poor speed control of the driving unit.

• Process-related changes, such as fluctuating load.

• A faulty speed reference, such as a poorly aligned photo tach.

• A magnetic pickup placed too far from the shaft.

Because the imbalance force varies with speed, the calculated

influence coefficients may be inaccurate. It is impossible to separate

force changes due to weight placement from those due to speed.

Trial run weights do not

produce at least a 30

percent change in the

imbalance vector for at least

one measurement location.

Use a heavier trial weight or different trial weight location to

increase the percentage change. Changes less than 30 percent can

cause incorrect correction weight calculations.

1xRPM magnitude and

phase do not average to the

same value after repeated

attempts, even with long

averaging times (several

minutes).

Get a synchronous average of the peak or acquire a high resolution

spectra to confirm the peak is 1xRPM. If the readings are not

consistent and repeatable, the calculated balance correction is

invalid.

Loose parts may cause this issue.

Balance

MHM-97432 Rev 7 359

Loading...

Loading...