CNC 8070

13

·239·

(REF: 1709)

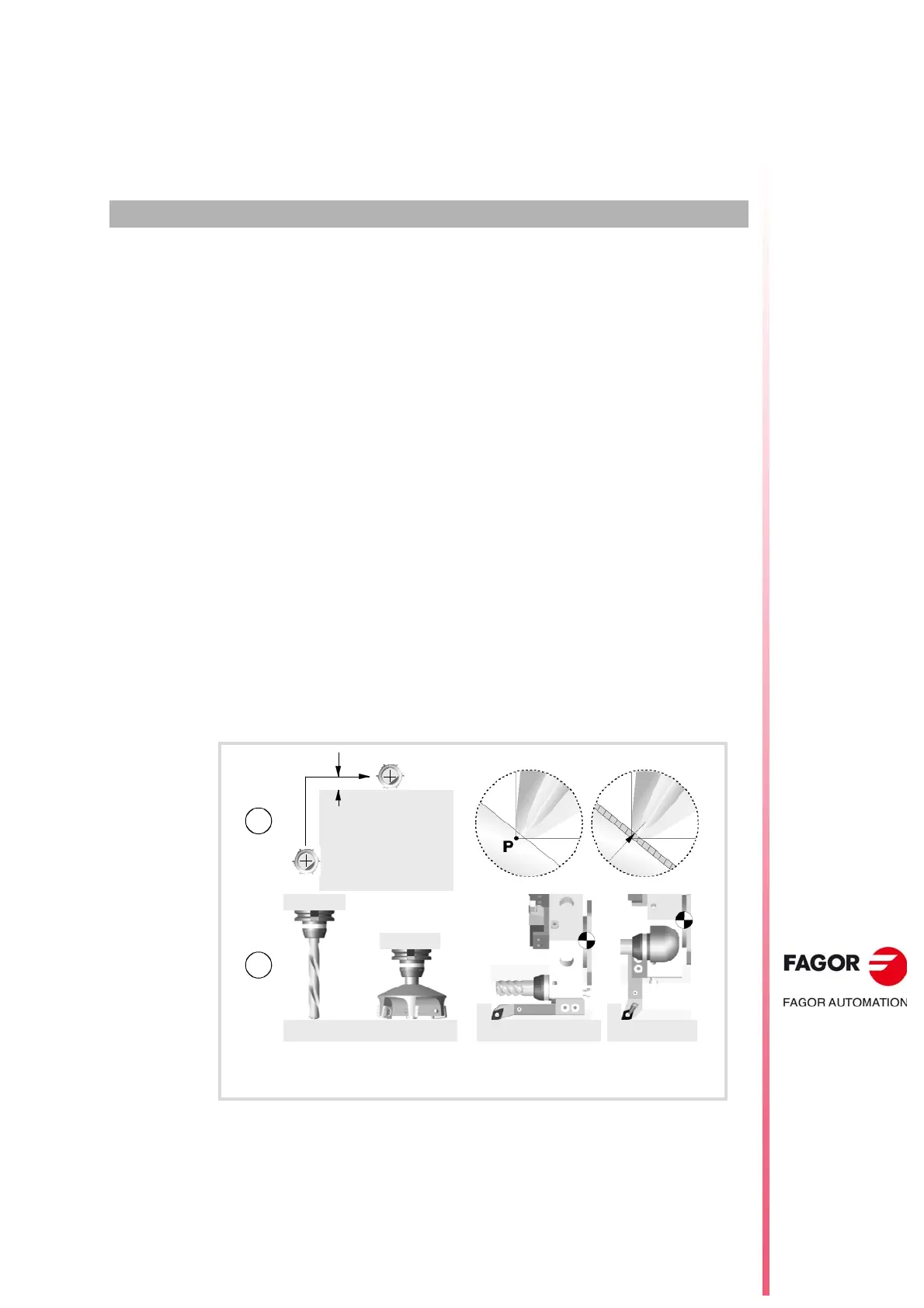

TOOL COMPENSATION

Tool compensation allows programming the contour to be machined based on part

dimensions and without taking into account the dimensions of the tool that will be used later

on. This way, there is no need to calculate and redefine the tool path depending on the radius

and length of each tool.

Types of compensation

Tool radius compensation (milling).

When working with tool radius compensation, the tool center follows the programmed path

at a distance equal to the tool radius. Thus obtaining the right dimensions of the programmed

part.

Tool radius compensation (lathe).

The CNC assumes as theoretical tool tip (P) the result of the sides used when calibrating

the tool. Without tool radius compensation, the theoretical tool tip (P) travels the programmed

path leaving machining ridges in incline and curved sections. With tool radius compensation,

it takes into account the tool tip radius and the location code (shape) or type of tool obtaining

the dimensions of the programmed part.

Tool length compensation.

When working with tool length compensation, the CNC compensates for the length

difference between the different programmed tools.

(A)Compensación de radio.

(B)Tool length compensation.

Loading...

Loading...