Programming manual.

CNC 8070

CREATING A PROGRAM.

1.

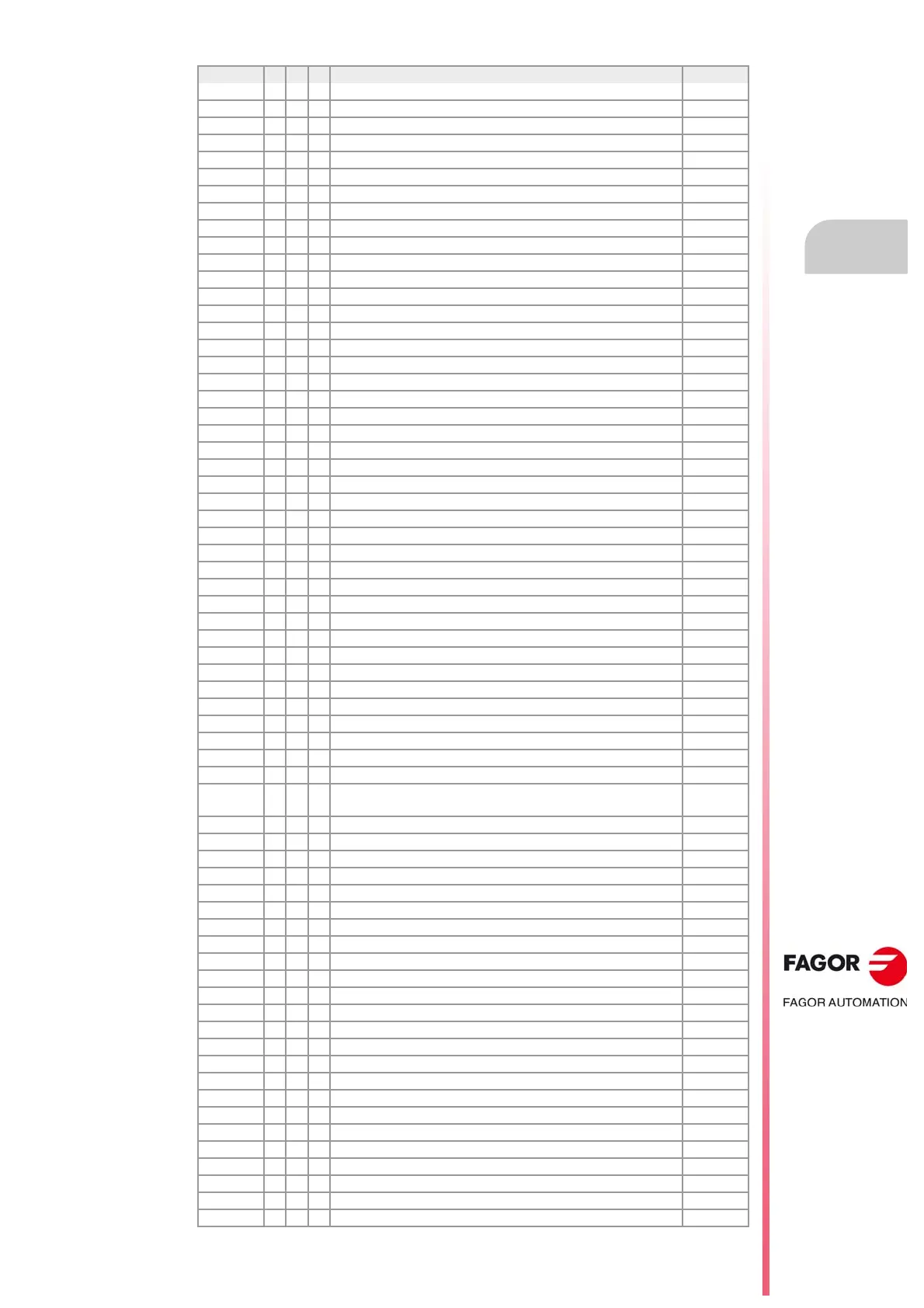

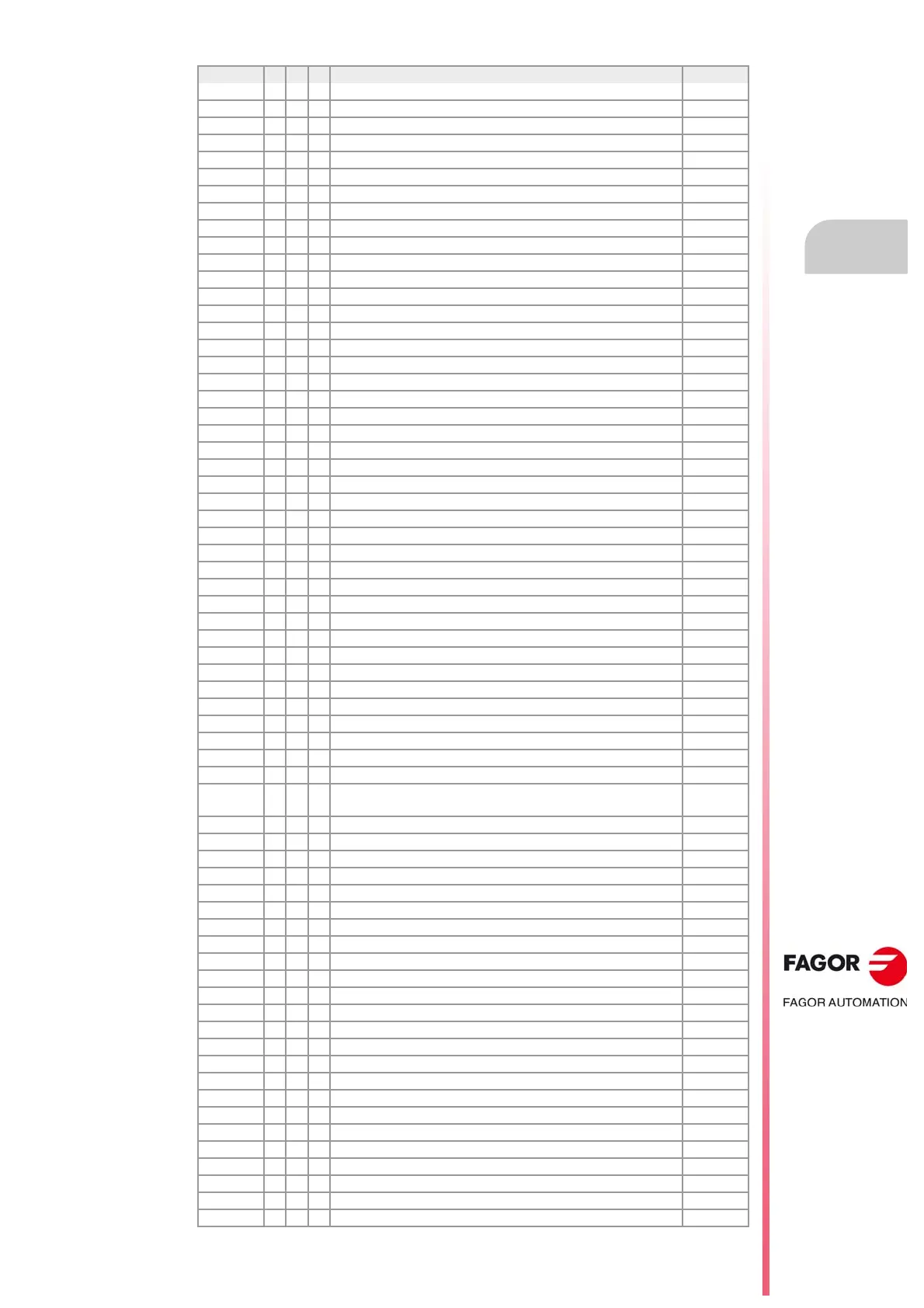

List of "G" functions.

·41·

(REF: 1709)

G57 ! * Absolute zero offset 4. 5.5

G58 ! * Absolute zero offset 5. 5.5

G59 ! * Absolute zero offset 6. 5.5

G60 * Square corner (not modal). 11.1

G61 * Controlled corner rounding (not modal). 11.3

G63 * * Rigid tapping. 10.3

G66 * (·T· model). Pattern repeat canned cycle. - - -

G68 * (·T· model). Stock removal cycle along X axis. - - -

G69 * (·T· model). Stock removal canned cycle along Z axis. - - -

G70 * ? * Programming in inches. 3.1

G71 * ? Programming in millimeters. 3.1

G72 * Scaling factor. 11.10

G73 * * Rotation of the coordinate system. 11.9

G74 * Machine reference zero (home) search. 2.4

G80 * * (·M· model). Canned cycle cancellation. - - -

G81 * * (·M· model). Drilling canned cycle. - - -

G81 * (·T· model). Turning canned cycle for straight sections. - - -

G82 * * (·M· model). Drilling canned cycle with a variable peck. - - -

G82 * (·T· model). Facing canned cycle for straight sections. - - -

G83 * * (·M· model). Deep-hole drilling canned cycle with constant peck. - - -

G83 * (·T· model). Drilling / tapping canned cycle. - - -

G84 * * (·M· model). Tapping canned cycle. - - -

G84 * (·T· model). Turning canned cycle for curved sections. - - -

G85 * * (·M· model). Reaming canned cycle. - - -

G85 * (·T· model). Facing canned cycle for curved sections. - - -

G86 * * (·M· model). Boring canned cycle. - - -

G86 * (·T· model). Longitudinal threading canned cycle. - - -

G87 * * (·M· model). Rectangular pocket canned cycle. - - -

G87 * (·T· model). Face threading canned cycle. - - -

G88 * * (·M· model). Circular pocket canned cycle. - - -

G88 * (·T· model). Grooving canned cycle along the X axis. - - -

G89 * (·T· model). Z axis grooving canned cycle. - - -

G90 * ? Programming in absolute coordinates. 3.2

G91 * ? * Programming in incremental coordinates. 3.2

G92 ! * Coordinate preset. 5.4

G93 * * Setting machining time in seconds. 6.2.1

G94 * ? Feedrate in millimeters/minute (inches/minute). 6.2.1

G95 * ? * Feedrate in millimeters/revolution (inches/revolution). 6.2.1

G96 * * Constant surface speed. 7.2.2

G97 * * Constant turning speed. 7.2.2

G98 * * (·M· model). Withdrawal to the starting plane. - - -

G99 * * (·M· model). Withdrawal to the reference plane at the end of the

canned cycle.

- - -

G100 * Probing until making contact. - - -

G101 * Include probe offset. - - -

G102 * Exclude probe offset. - - -

G103 * Probing until not making contact. - - -

G104 Probe movement up to the programmed position. - - -

G108 * * Feedrate blending at the beginning of the block. 6.2.2

G109 * Feedrate blending at the end of the block. 6.2.2

G112 * Changing of parameter range of an axis. 12.4

G120 ! Set lower linear limits of the work zone. 11.11.2

G121 ! Set upper linear limits of the work zone. 11.11.2

G122 * Enable/disable the work zones. 11.11.3

G123 ! Set circular limits of the work zone. 11.11.2

G130 * * Percentage of acceleration to be applied per axis or spindle. 6.2.5

G131 * * Percentage of acceleration to be applied, global. 6.2.5

G132 * * Percentage of jerk to be applied per axis or spindle. 6.2.6

G133 * * Percentage of jerk to be applied, global. 6.2.6

G134 * * Percentage of Feed-Forward to be applied. 6.2.7

G135 * * Percentage of AC-Forward to be applied. 6.2.8

G136 * * Circular transition between blocks. 13.1.2

G137 * * Linear transition between blocks. 13.1.2

G138 * * Direct activation/cancellation of tool compensation. 13.1.2

G139 * * Indirect activation/cancellation of tool compensation.

13.1.2

G145 Freeze tangential control. 18.2

G151 * * * Programming in diameters. 3.1

Function M D V Meaning

Loading...

Loading...