smart.Turn units | Units – Threads

2

166

HEIDENHAIN | User's Manual smart.Turn and DIN Programming | 12/2017

API thread unit

This unit cuts a single or multi-start API thread. The Thread depth

decreases at the overrun at the end of thread.

Unit name: G352_API / cycle: G352

Further information: "Tapered API thread G352", Page 357

Thread form:

O: Thread location:

0: Internal thread (infeed in +X)

1: External thread (infeed in -X)

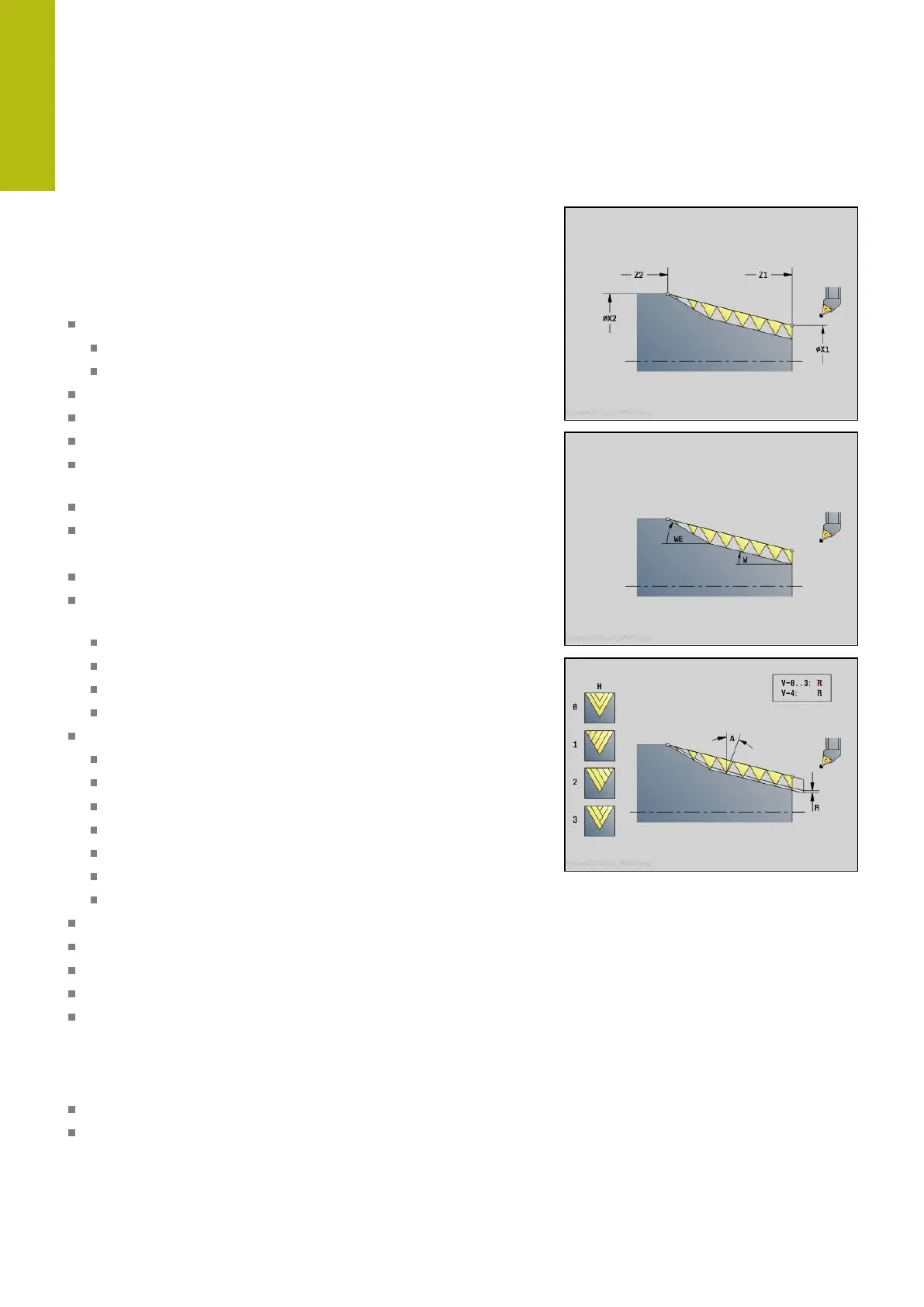

X1, Z1: Start point thread

X2, Z2: End point thread

W: Taper angle (range: –45° < W < 45°)

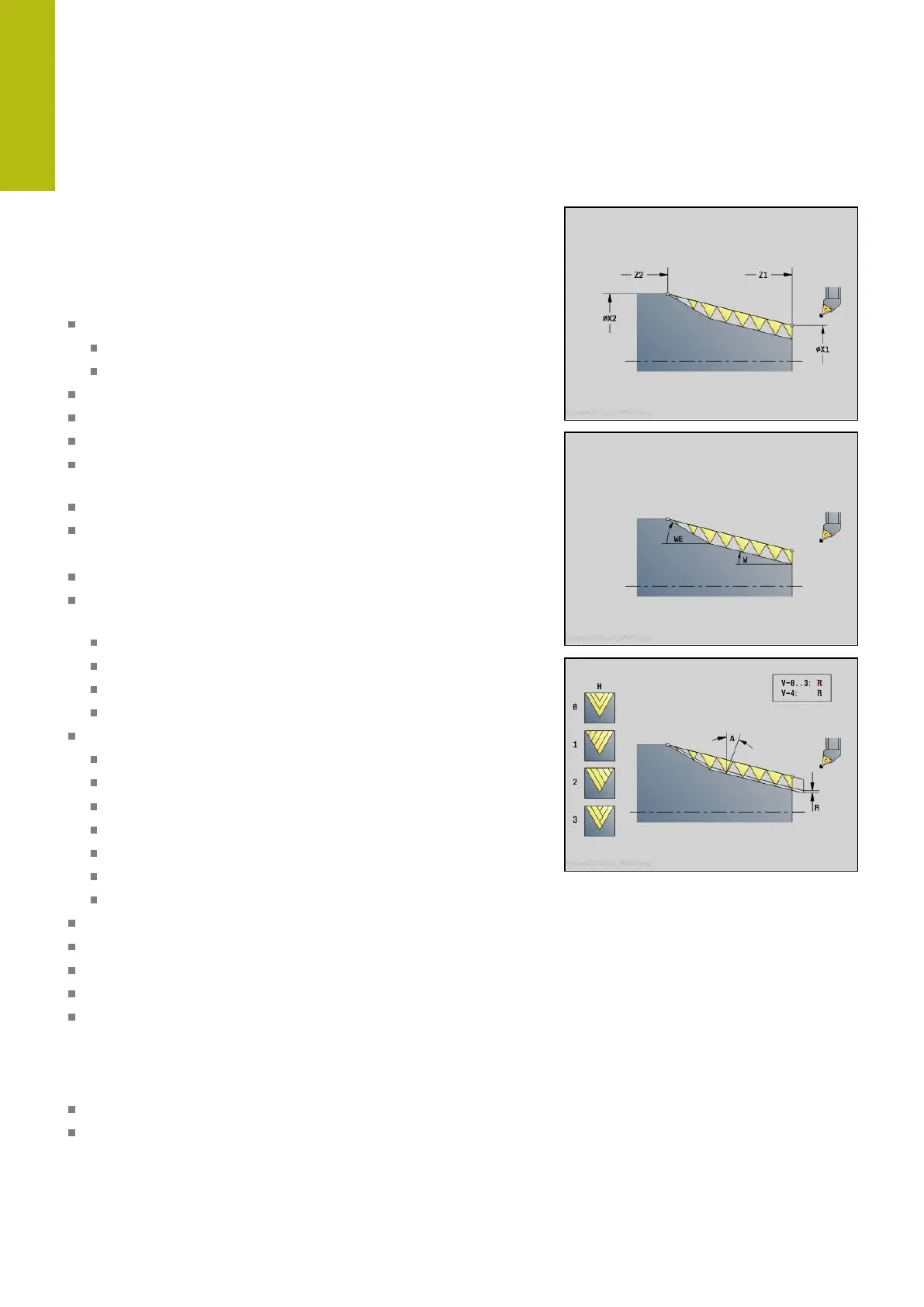

WE: Run-out angle (reference: Z axis; 0° < WE < 90°; default:

12°)

F1: Thread pitch

U: Thread depth

Cycle form:

I: Max. approach

H: Type of offset – offset between the individual infeeds in the

cutting direction

0: Without offset

1: From left

2: From right

3: Alternating left/right

V: Type of infeed

0: Const. mach. X-section

1: Const. infeed

2: EPL with distrib. of cuts

3: EPL w/o distrib. of cuts

4: MANUALplus 4110

5: Constant infeed (4290)

6: Const. w/ distrib. (4290)

A: Approach ang. (range: –60° < A < 60°; default: 30°)

R: Remaining cut depth (V=4)

C: Start angle

D: No.gears

Q: Number no-load.

Further forms:

Further information: "smart.Turn unit", Page 78

Access to the technology database:

Machining operation: Thread cutting

Affected parameters: F, S

Loading...

Loading...