GAPS - User Guide

10.1.4 MAINTAINING SUBCONN CONNECTORS

System:GAPS Preventive Maintenance

Sub-system: SUBCONN connector Reference: PM01 Page: 1/1

Subject: Cleaning and greasing

SUBCONNconnectors

Maintenance level: 1

Periodicity: Every time before mating

Duration: 5 minutes

Equipment

Isopropyl alcohol, Loctite 8021 medium grease

Precaution

Disconnect by pulling straight, not at an angle.

Do not pull on the cable and avoid sharp bends at cable entry.

When using a bulkhead connector ensure that there are no angular loads.

Do not over tighten the bulkhead nuts.

SUBCONN connectors should not be exposed to extended periods of heat or direct sunlight. If

a connector becomes very dry, it should be soaked in fresh water before use.

We recommend to replace the SUBCONN connector every 4 years.

Preliminary

Steps

None

1. Remove any accumulated sand or mud on the connector using spray based contact cleaner

(isopropyl alcohol).

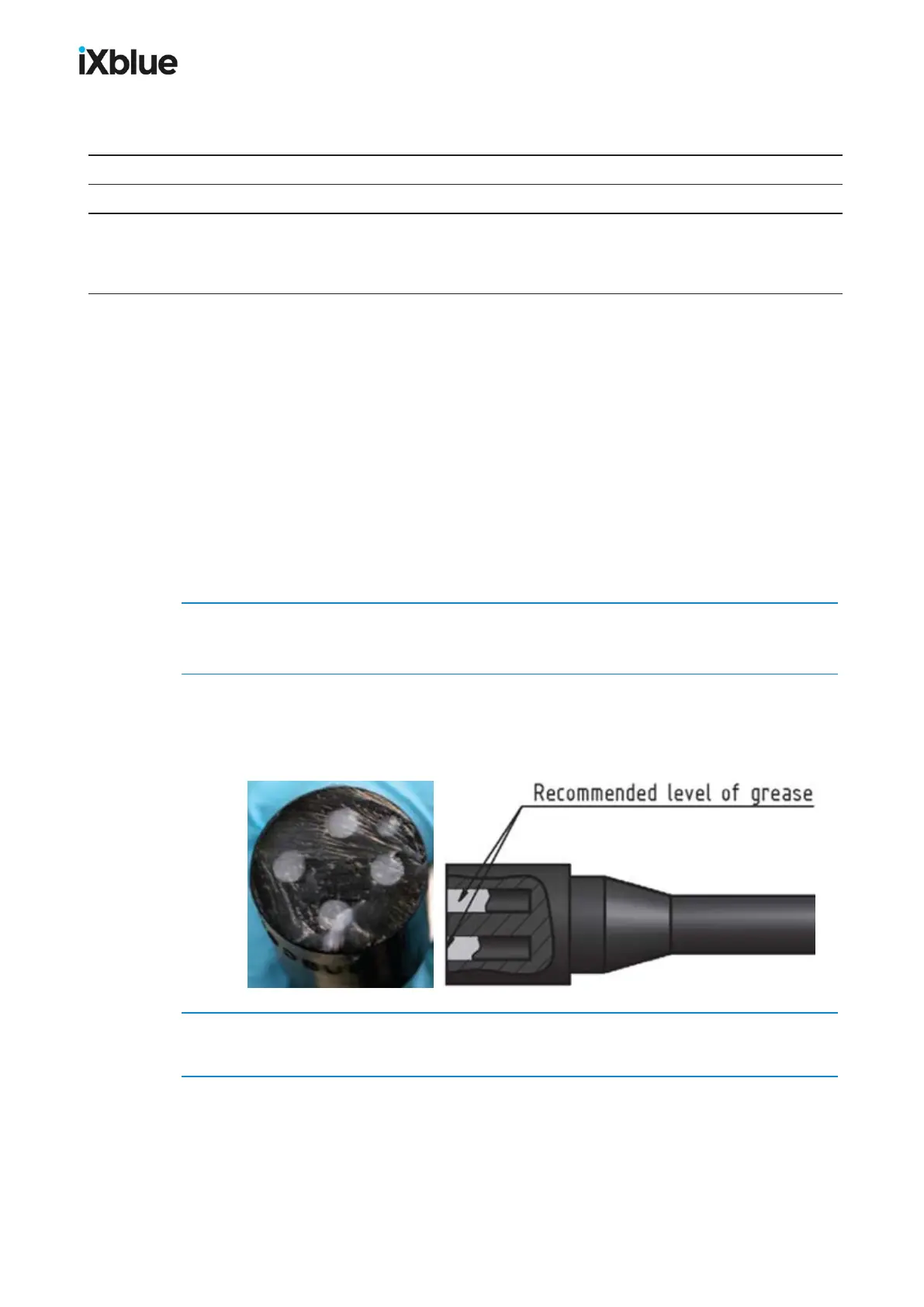

2. Apply a layer of grease corresponding to approximately 1/3 of socket depth to the female

connector.

All sockets should be completely sealed, and transparent layer of grease left visible on the

face of the connector.

3. After greasing, fully mate the male and female connector and remove any excess grease from

the connector joint.

160 MU-GAPS-AN-005-H - November 2019

Loading...

Loading...