Manitowoc Published 08-12-19, Control # 224-13_v2 4-65

MLC650 OPERATOR MANUAL SET-UP AND INSTALLATION

Installing the First Crawler (continued)

See Figure 4-52 for the following procedure:

Figure shown without lifting jack cylinders for clarity.

NOTE: The crawler pins (4) are shipped in the retracted

position to meet shipping width requirements.

The collars (1a) are stored on the carbody and are

secured with retaining pins (2a) and hair-pin cotter

or safety pins (3a).

Reference Table 4-3

for swing limits during crane assembly

and disassembly.

14. Slowly lower the crawler, mast up, and swing to engage

the crawler hooks (5) with the carbody pins (6).

15. Stop lowering when the crawler hooks are fully engaged

and the carbody pins and the connecting holes are

aligned.

16. Using the remote control, deploy the crawler pin (4).

17. Secure the crawler pin with collar (1b), the retaining pin

(2b), and the cotter pin (3b) on the front and rear of the

crawler.

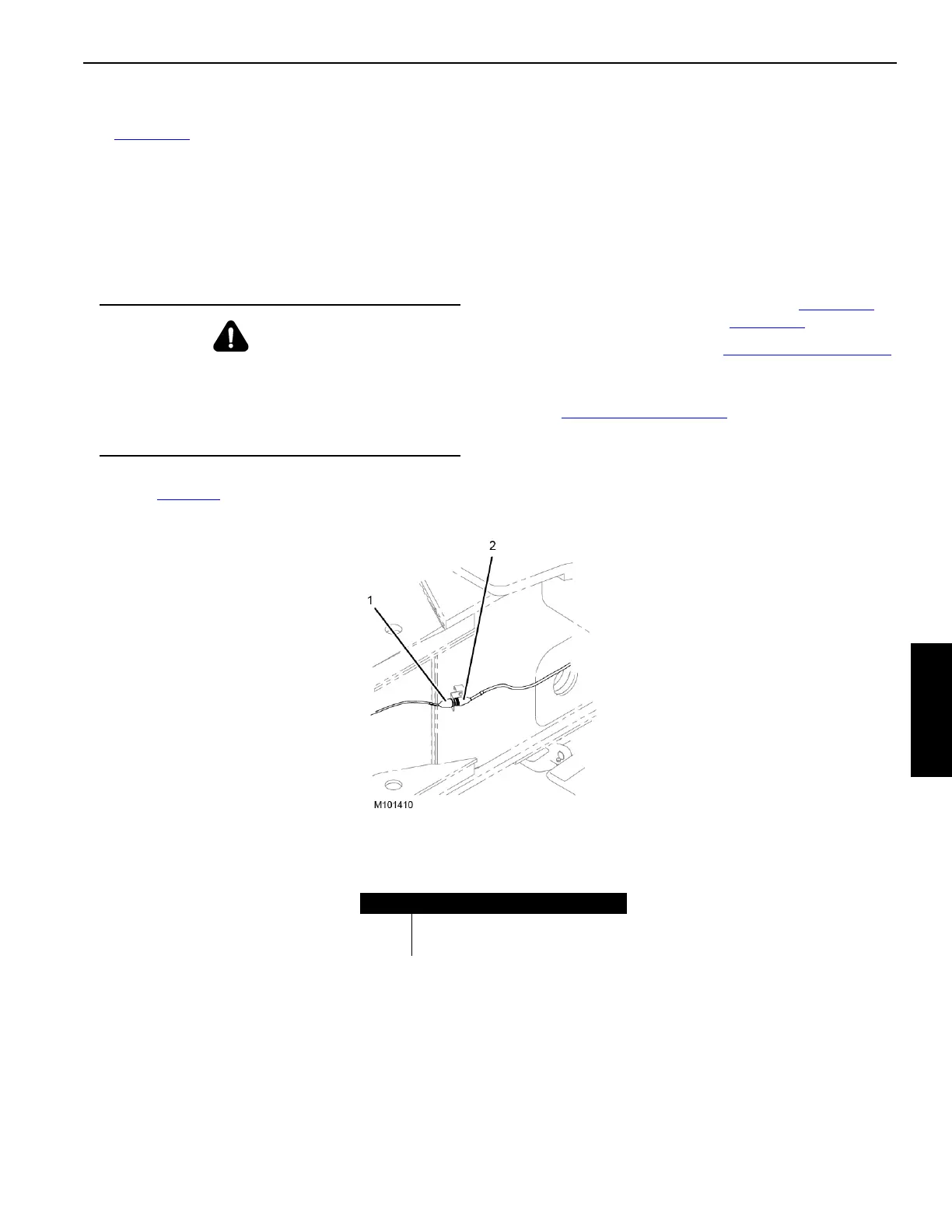

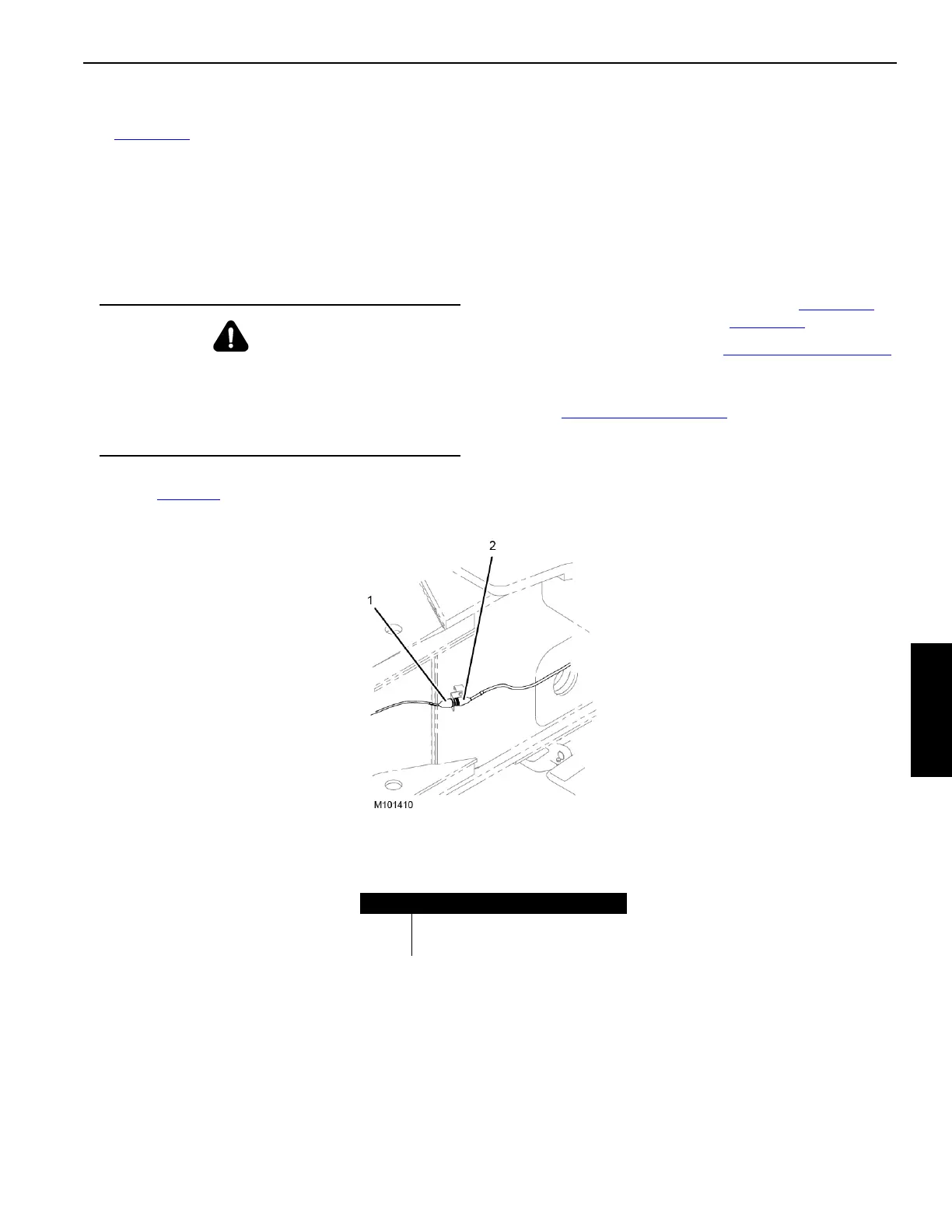

18. Connect the carbody electrical cable (1, Figure 4-53

) to

the crawler electrical cable (2, Figure 4-53

).

19. Remove the slings (2 and 3, Figure 4-50 on page 4-62

)

from the lifting brackets on the crawler frame.

20. Remove the pins from the crawler lifting brackets

(6a, Figure 4-50 on page 4-62

), place the lifting brackets

into the stored position, and secure them with pins and

safety pins.

WARNING

Crane Tipping Hazard!

To avoid serious or fatal crushing injury, do not

exceed operating radii and capacities given in the

Liftcrane Mast Handling Capacities Chart. Structural

failure or crane tipping will occur.

FIGURE 4-53

Item Description

1 Carbody Electrical Cable (WLC2)

2 Crawler Electrical Cable (WLL1-P1)

Shown Without Lifting Jack Cylinders for Clarity

Loading...

Loading...